(Many thanks to Ian Roy for identifying much of the information on this page).

Shotts Sand-Lime Brickworks, Shotts, North Lanarkshire aka locally as the ‘White Brickworks’.

See also:-

Northfield Brickworks, Shotts. (Note – SBH – The 1985 publication ‘A survey of Scottish brickmarks’ suggests these were two different brickworks albeit they were situated very close together. Northfield – NS884600. Shotts Sand-Lime – NS884602).

1921 – A short history of the Shotts Iron Company Limited by Augustus Muir … (Shotts Iron Company were carrying out many improvements and extensions) … these included the completion of the turbo-blower at the ironworks, the installation of new boilers, additions to the foundry, the construction of slag brickmaking plant and many other items (P42) …

1924 – A short history of the Shotts Iron Company Limited by Augustus Muir … In view of the large stock of pig iron in the Company’s hands, an old problem once more cropped up – whether the furnaces should be damped down to avoid further losses or should be kept in blast because of the by-products plant. Although the directors decided to keep them in blast for the time being, they were compelled to damp them down before the autumn. In consequence, there was no longer any slag, so that the slag-brickworks had to be stopped, and the lime that was being supplied under contract from Clippens had to be stored until the furnaces were again working … (p 44).

06/05/1924 – The Scotsman – Electrical engineer’s visit to Shotts Works – Members of the West of Scotland branch of the Association of Mining Electrical Engineers to the number of 174 visited Shotts Works on Saturday at the invitation of the Shotts Iron Company (Ltd). The visit was instructive from the point of view of the application of electricity to the manufacture of iron, production of coal and the manufacture of bricks. The various sections of the works visited were the furnaces, the powerhouse, Northfield Colliery where all power including winding, is electric, the ore briquette works where fine ore is made into briquettes for feeding into the furnaces and the slag brickwork where a composite brick of slag and lime is made. At the luncheon, which was later provided by the board of directors, Mr Brown presided.

1925 – Scottish Valuation Rolls – 1471 – Slag Brickmaking Plant, Shotts Ironworks – Shotts Iron Company Limited and 1472 – Slag crushing sheds and machinery, Shotts Ironworks.

23/10/1925 – Carluke and Lanark Gazette – Carlukes new houses. The minute of the Public Health meeting of 21st September bore that a letter was read from Messrs Bryce & Symington, contractors for the brick work of the 84 houses to be built at Carluke, stating that they were now prepared to build these houses with Hallcraig composition bricks at the same contract price as their tender accepted for the building of the houses with Shotts slag bricks and the Committee agreed to the amendment of the contract with Messrs Bryce & Symington to allow of the substitution of Hallcraig bricks. The Committee thereafter reconsidered the contracts for the 16 houses at Law, 16 houses at Carnwath and 4 houses of three apartments at Carstairs. in each of which it had been agreed to build with Shotts brick on account of the saving of cost as compared with composition bricks. The Clerk reported that the contractors for the houses at Law were not prepared to reduce the amount of his offer for building with composition brick; that the contractors for the houses at Carnwath had already entered into a contract with the Shotts Iron Coy., for the delivery of their bricks on the job, and that the Shotts bricks for the four houses at Casatairs were already on the site and the work well advanced. In view of these circumstances, and having regard to the fact that, if any of these contracts were increased by preferring composition bricks, the price per house authorised by the Scottish Board of Health for the whole scheme would he exceeded the Committee resolved to abide by the tenders as accepted.

1926 – A short history of the Shotts Iron Company Limited by Augustus Muir … there followed the disastrous strike of 1926, which began on 1st May. The limestone miners at

Clippens followed the lead of the colliers, and foundry moulders stopped work also. The blast furnaces were blown out. Briquetting works were closed, but the manager endeavoured to keep the brickworks going … (P45).

27/05/1927 – Musselburgh News – Elizabeth Walker, (19), High Street, Shotts, employed as machine lifter at the slag brickworks, belonging to Shotts Company. Ltd., had her right arm severed between the elbow and the shoulder through being caught in a revolving shaft on Tuesday. She was removed to Glasgow Royal Infirmary.

24/06/1927 – Midlothian Advertiser – Shotts local notes … For failing to fence a revolving shaft in the slag brickworks, whereby a girl had lost an arm, Shotts Iron Company was fined £2 at the Sheriff Court. It was pointed out that it was extremely difficult to fence the shaft …

1930s – The 1985 publication ‘A survey of Scottish brickmarks’ suggests these works were operated by Shanks & McEwan during this time.

09/04/1930 – Dundee Evening Telegraph – Dundee’s new primary school … the surrounding wall of the playground on the southern side of the school and the railing walls are built of Shotts grey brick …

Below – 21/10/1932 – Midlothian Advertiser – Encouraged by the demand for Shotts bricks, Shotts Iron Company. Ltd.. have opened a new brickwork at Shotts. Employment will be provided for 50 workers.

09/09/1933 – Falkirk Herald – Falkirk foundry men’s visit of inspection to Shotts Works – Faith in the Future … The visitors then had an inspection of the two brickworks and they viewed the making of composition and grey brick from the company’s? products, the two works having a capacity of nearly 60,000 per day. Adjourning to the work offices, which are built entirely of Shotts grey bricks the visitors had the opportunity of witnessing an exhibit of the company’s various products – many varieties of coal, ironstone, pig iron, limestone, bricks, hydrated lime, grit etc … Mr Matthew Brown, Managing Director of the Company.

16/07/1936 – The Scotsman – The stoppage of work at the Shotts Brickwork, belonging to the Shotts Iron Company ( Ltd . ), entered its third day yesterday. The strike affects about 50 workers, mostly youths, who are making a demand for increased wages. The management refuse to discuss their claims until a resumption of work is made. (Note – SBH – I am uncertain which Shotts brickworks this refers to – could be Northfield).

18/07/1936 – The Scotsman – The strike at Shotts Brickworks, belonging to the Shotts Iron Company ( Ltd . ), ended yesterday in the return of the strikers to work unconditionally. The strike which commenced last Monday morning, affected fifty workers, who demanded increased wages. (Note – SBH – I am uncertain which Shotts brickworks this refers to – could be Northfield).

18/12/1937 – The Scotsman – Shotts Iron Company Limited … from the furnaces there is of course, also a large production of slag, much of which is now made into slag bricks and the balance is treated for road purposes. In addition to these slag bricks, the company has in operation at Shotts a composition brick making plant which has been producing 12 million bricks per annum. These bricks have a ready outlet in the existing building demand. A new brickwork has been erected at Roslin Colliery and is now in operation. These new bricks are of first-rate quality and are commanding a ready market. It is the company’s intention to double the productive capacity before next June …

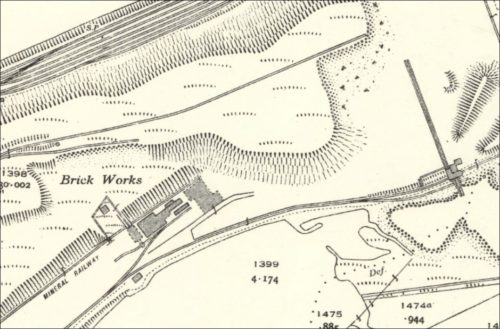

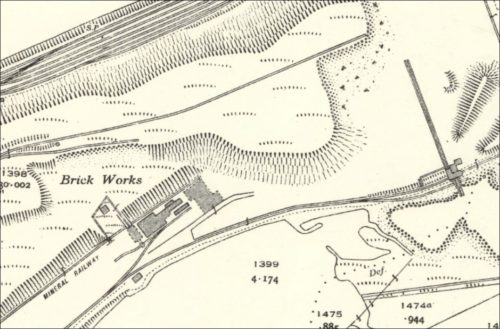

Below – 1939 – Shotts Sand-Lime Brickworks, Shotts.

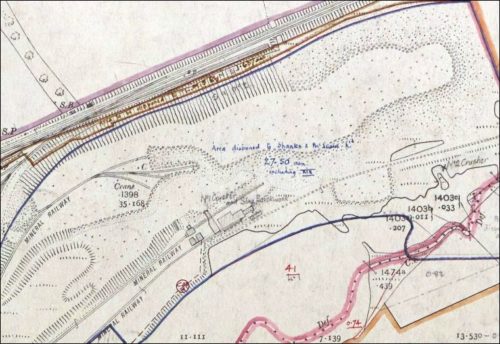

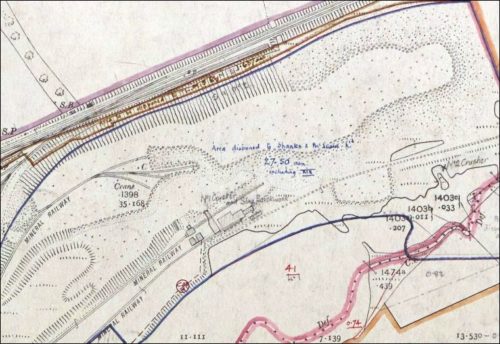

Below – A very similar map with notations by Ian Roy showing the locations of Crusher 1 and 2 associated with the brickworks.

19/10/1939 – Dundee Evening Telegraph – Super cinema for Newport, Dundee … St Mary’s Lane off Cupar Road … a colourful touch is provided externally, the frontage being of Shotts bricks with white cement facing and roof of red asbestos …

1940 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests these works were demolished by 1940.

28/10/1940 – The Scotsman – Brickmaking from slag. Alongside suggestions which have been made that blast furnace slag, should be used in the manufacture of cement, proposals have been put forward to utilise slag for brick-making. As with blast furnace slag cement, the production of slag bricks is an old story in Scotland. The Shotts Iron Co ., Ltd ., has long turned out blast furnace slag bricks, though it does not engage in cement manufacture. The basis is granulated slag, the gravel-like material produced by running the molten slag from the blast furnace into a stream of water. In brick-making, the granulated slag is pressed in steam-heated moulds, without the kiln burning, which is a feature of ordinary brick production. After weathering for several months, the bricks are ready for use. The whole process is, of course not quite so simple as all that, as care has to be taken in getting the right quality of slag and recent changes in the types of ores used in the blast furnaces have posed certain problems. Though they have been the butt of many criticisms in past years, the Scottish blast furnace operators have in fact pioneered many forms of by-product utilisation. When they introduced methods of recovering by-products from splint coal-fed blast furnaces in the early seventies of last century, they showed the way for the development of by-product coke ovens. In essence, the full utilisation of by-products depends on local conditions, and especially on the raw materials available. No universal rule can be laid down as to what can and what cannot be recovered. Certain slags may be quite useless for cement or brick-making it all depends on the compound nature of the material; for instance, the proportion of lime, silica, or alumina.

20/12/1940 – The Scotsman – Shotts Iron Company Limited – Material improvement in cash position. Chairman Mr C. Augustus Carlow. Mr Matthew Brown retiring after 25 years with the company … Brickworks – In the early months of the war, the demand for bricks was poor but in later months the position improved very materially, resulting in a total production for the financial year of approximately 14 million composition bricks in addition to which there was a substantial increase in the sale of our Shotts grey slag bricks …

24/01/1941 – The Scotsman – Richard Conway, a young brickworker, 138 Springhill Road, Shotts, was accidentally killed while at work at Shotts Brickwork. Conway slipped in front of a waggon which was being pushed forward and the wheels passed over him. (Note – SBH – I am uncertain which Shotts brickworks this refers to – could be Northfield).

Below – The Scottish Industrial Archaeology Survey published a report in 1985 entitled ” A survey of Scottish brickmarks. During the compilation of this report in which the survey officers visited working and derelict brickworks sites, many items of interest were donated or found. Many of these items were thereafter donated to the National Museum Scotland. The item below is one of these items. It is a brick, stamped very faintly with ‘Shotts’. The composition of the brick has a very sandy lime look with an additional black material. Perhaps it is a composite brick of slag and lime as referred to in the 06/05/1924 article above.

2012 – History Group Bulletin – Northfield Brickworks, Shotts – As a young boy growing up in the High Street between 1950 and 1960, I remember it was a busy thoroughfare with heavy and light transport trundling up and down from an early hour. Similarly, there was also a steady stream of workers making their way to various jobs in the foundry, workshops, Northfield Colliery and Northfield Brickwork. My interest in Northfield Brickwork was stimulated by my dad as he started as a young lad in the ‘white brickwork’ and moved to Northfield Brickwork on his return from the army. I always looked forward to our evening walks, where the ‘Voe’ was a popular destination. The remnants of the ‘white brickwork’ were still evident at this time, as was the slag hill which provided the material to produce the distinctive finished grey brick for general building. Although Northfield Brickwork was accessed from the High Street, it was located close to the bottom of Charles Street in Torbothie. At this time, Northfield Brickwork was still in production, making an orange coloured common building brick made from crushed ‘blaes’. Although I was never employed by Northfield Brickwork, as an apprentice electrician with the Central workshops I was involved with ongoing maintenance and repairs. Northfield Brickwork started off as a briquette work as far back as 1896 and was owned by the Shotts Iron Company. The then furnace manager saw a niche to make a useful product from the iron ore dust, which at that time was considered waste. Subsequently, he took out a patent to process the dust and a plant was built to produce iron ore briquettes. These briquettes were then added to the furnace, in turn, increasing the yield of iron ore. Demand for iron ore decreased and thus, the need for iron ore briquettes. Modifications to the existing machinery in the briquette work were made to enable the production of building bricks. Northfield Brickwork consisted of two pan mills, three brick presses and two kilns. The process began with ‘blaes’, a pit bing waste mainly from Northfield Colliery, which was transported by railway wagons to the two pan mills. On arrival, men would then shovel the ‘blaes’ into the pan mills where it was crushed by two large rotating rollers into a fine dust. This fine dust passed through the perforated floor of the mill into a collection pit. Bucket

elevators then collected and lifted the fine dust from the pit to an area above the press machines, known as the loft. From here the dust went down into a mixer where it was mixed with oil and water before moving onto a rotating table which gave the brick its initial rough shape. The water used for the mixing process was pumped from the Voe by a D10 Mono pump housed in a small brick building next to the by-wash. Exiting from the turntable, the rough pre-formed brick was pressed to size and the ‘Shotts’ stamp imprinted. Although they were shiny black in colour, they were termed ‘green’ bricks. From here the ‘green’ bricks were taken to the kilns where workers, known as setters, built them in a specific fashion to allow the firing flame to pass through the stacks, commencing the process of turning them into the finished brick. The kilns used in this process were modelled upon the Hoffmann design. They were fired with beans of coal and access ports of the top of the kilns provided a means to control the firing of the bricks. The brick firing areas were arched in shape and controlled by dampers linked to a ventilation fan. As the kilns had no individual chambers, this firing process was continuous.

Once the bricks were placed inside the kilns, the entrance doors were bricked up and daubed with fire clay to seal the chamber. It was then up to the kiln burner, who worked above the kilns, to observe conditions and fire it accordingly. The kiln burner was responsible for ensuring the fire passed into the next kiln of bricks ready to be fired. Interestingly, the fire was lit after the Fair holidays and continued to burn until the start of the following Fair holiday. When the flame had moved on, workers, known as strippers, removed the bricks from the kilns. This task was a hot and dusty occupation. The bricks were then loaded directly onto lorries from the kilns and transported to customers in places such as Cumbernauld, Dunblane and as far afield as Campbeltown. Surplus bricks were also stored in the stockyard, which was a good yardstick for determining the state of the building industry. In the 1960s, the internal rail network delivering the raw material was replaced by road transport necessitating improvements to the established system. A pre-crusher conveyor system was installed transporting the ‘blaes’ on conveyor belts to a crusher, which reduced its size before entering the pan mills. The internal transport of the bricks was also improved by the installation of another conveyor system, which transported the "green" bricks from the presses into the kilns. As a result of an influx of finished brick from England, the demand for common brick declined and so too did the demand for Shotts brick. The production of common brick at Northfield Brickwork slowly declined until its closure in the mid-1980s. The closure of the brickwork was a great loss to the workers, not only as a means of employment, but also the loss of friendships and social status associated with working within a local production environment. It was once said that ‘Shotts lit the world’ but it might also be said that ‘Shotts built the world’ through the production of a quality brick product.

Bobby Fleming