Canmore – Craigend Refractories Ltd, Falkirk

Craigend Brickworks Ltd was established in 1938 on the site of the drift mine at Craigend, Falkirk, leased to the company by Carron Co. The works closed in 1943 due to lack of demand for bricks but re-opened after the war. The name was changed to Craigend Refractories Ltd in February 1972 (Note – SBH – I believe this date is wrong)and the company was sold to Amalgamated Anthracite Holdings Ltd. In 1983 the Carbrook Mine and Craigend Works were closed and the remaining assets and trade names sold to the Burn Fireclay Co of Morpeth.

Canmore – Carbrook Fire Clay Mine. Closed October 1982.

*****************************

William Wilson founded the works in 1937 on the site of Whiterigg and Craigend Collieries (Carron Company). He also opened the Carbrook Mine to supply the brickworks with fireclay.

In 1964 the pit blae supply was exhausted and the works concentrated on making refractories. In 1982 the Carbrook Mine only worked in response to demand from the Craigend works. Carbrook was Scotland’s last fireclay mine and it closed in Oct 1982. The clay was transported from the Carbrook Mines by lorries hired from William Grants. Originally 100 people were employed by the mine. 1979 – 20 people worked the mine and delivered 200 tons of clay per day.

1937 – 1938 – Works started. Craigend Brickworks ltd.

1943 – Works closed during the war due to lack of demand for bricks.

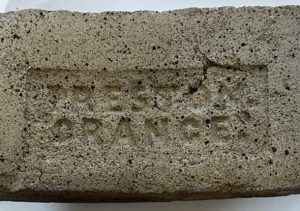

Below – 1944 – 1967 – Craigend Brickworks.

16/07/1949 – Falkirk Herald – Mr and Mrs James Rushford and son, Boxton, Avonbridge wish to thank all friends and neighbours; also the staff and employees of Craigend Brickwork for presents received and expressions of goodwill on their departure to Canada.

16/06/1951 – Falkirk Herald – Craigend Brickworks are referenced after staff sent their condolences to a fellow worker following a family death.

23/06/1951 – Falkirk Herald – A party of 175 employees and friends of the Craigend Brickworks, Ltd., held their annual excursion to Rothesay last Saturday in ideal weather conditions. Following lunch, the party sojourned to Ettrick Bay, where an arranged programme of sports for young and old was carried through. A most enjoyable time was spent by all.

26/09/1953 – Falkirk Herald – Refractories chemist. State age, experience and salary required. Craigend Brickworks Ltd, Avonbridge, Falkirk.

31/12/1955 – Falkirk Herald – Craigend Brickworks Ltd advert. General manager wanted.

Craigend Brickworks Ltd. General manager to take charge of both commercial and industrial sides of works producing high-grade refractories, as well as common bricks, in Stirlingshire required immediately. Applications, giving full particulars of training, experience and technical qualifications, will be treated with absolute confidence, and should be sent to the Secretaries, Craigend Brickworks, Ltd., 30 Glasgow Road, Denny, Stirlingshire.

Below – 1956 – Craigend Brickworks.

Below – 25/04/1957 – Edinburgh Evening News –

Bricks from Craigend are being shipped all over the world but labour for this and the Glenelrig Brickworks has to be transported from outlying districts. The managing director at Craigend, Mr William H. Wilson (inset) has done much to improve the village amenities.

Standburn wants to stay on the map – The death knell sounded for the thriving little community of Standburn more than 20 years ago … In the meantime, on the site of a worked-out colliery, one local concern is carrying the village’s name to the world market. From Craigend Brickworks, fire bricks are being shipped to furnaces, steel works and ovens throughout Europe, Canada, Australia and the Middle East, the Argentine and many other export customers. On the home market too, the Craigend firm, which started with 12 workers in 1938distributes the Standburn product to British industry at home.

500,000 fire bricks(about 1200 tonnes) are loaded on railway sidings each day but to operate his works, managing director, William H. Wilson, who lives in Standburn, has to transport men from outside the village. Lorries travel to the Maddiston, Avonbridge, California and Whitecross areas to collect labour.

In an effort to improve village amenities, Mr Wilson has had a bus shelter built for the local people, has donated playing fields and is providing ornamental garden plots. His urgent call however is for a stable labour force.

The same call echoes from the other side of the village. At Glenelrig Brickworks, production development is held up by the lack of a steady force of suitable workers. Managing director John Reilly, who took over these works and started producing composition house bricks in January of this year, estimates that there are at least 30 years of life at his works. From an early output of 30,000 bricks a week, Mr Reilly now has men working on night and day shifts to push up production to 150,000 a week. A new mixture, which results in top quality bricks is Mr Reilly’s proud boast. The product of this successful blending of local raw materials assures a steady sale on the home market. With good local labour to keep machines in full operation, production could soon be developed from 600,000 bricks a month to 1,250,000. Meanwhile, lorries must be sent to other villages to transport the available workers.

12/01/1959 – The Glasgow Herald – Canadians buy Scottish bricks – Falkirk, Scotland. A concrete demonstration of how concentrated attention to developing exports to Canada, kept an industry going at full capacity while its competitors, dependant on the home market, were laying off men and closing down, was brought to my attention when I paid a visit to this district of Scotland. The primary object of the visit was to renew my acquaintance-ship with a new friend I had met while attending the Dollar Export Council Conference in Eastbourne early in December. He was William H Wilson, owner of the Craigend Brickworks at Avonbridge, near Falkirk.

At Eastbourne, he had told me something of his success in developing export business in Canada by going out there personally and making contacts with construction companies to which he could sell the major product of his plant, a high-quality type of firebrick. He urged me at the first opportunity to come to Scotland and visit his brickworks, and that is exactly what we have been doing.

As we visited the mine from which comes the clay that is the raw material for his industry, he told how his exports to Canada had kept his men in employment. He had visited Canada in the early summer of 1958, seeking new business to keep his works going, because there was a definite decline in the domestic market for his produce. Towards the end of the summer, he was faced with closing down operations because he had a large stockpile of clay and of completed bricks. Other brickworks were closing down.

Then came a rush of orders for Canada, enough to keep his plant and its workers busy until well on into 1960. The clay mine had to be put into full operation to meet these Canadian demands, and there has been full employment at Craigend Brickworks.

Source Falkirk Museum and Archives Craigend Refractories, Craigend, Avonbridge. 1937 – c. 1982.

William Wilson founded the Company in 1937 but the WW2 caused it to close. In 1982 it was owned by Amalgamated Anthracite Holdings – AAH. Mr Stewart and Mr Forbes Hendry provided capital for the works to be built on the site of the Craigend Colliery which produced coking coal for the Carron Company. The enterprise was a private limited company and consisted of 5 shareholders and Mr Wilson who became MD. The firm managed to open for a few months in 1940 but it did not begin production until after the war. During the 1960’s Craigend Brickworks sold out to a Welsh Company and became known as Craigend Refractories. In 1964 the pit bing required to make common bricks became and the works began to manufacture firebricks with clay from the Carbrook Mine in Torwood. Bauxite was obtained from New Guinea. Some bricks were specifically produced for local firms eg fire grates for Smith and Wellstood Bonnybridge.

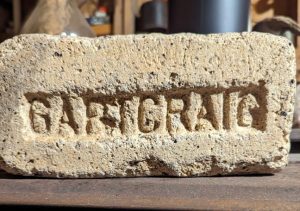

1961 – 1962 – A directory of British clay products and manufacturers – Craigend Brickworks Limited, Avonbridge, Falkirk, Stirlingshire. Tel.Polmont 244-5. Fire bricks and composition bricks. Tradename – Craigend.

c. 1964 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that Craigend Refractories Ltd were the owners.

Below – 26/09/1968 – The Scotsman – Craigend Brickworks Ltd advert … shipping throughout the world … a member of the Thistle Holdings Group.

Below – 16/10/1970 – The Scotsman – Craigend Refractories advert. Representative required. Apply to the managing director Mr C. G. Yuill.

08/11/1972 – The Scotsman – AAH have bought Craigend Refractories from Thistle Industrial Holdings for £218,000 in cash. Craigend have recently broadened their activities after the completion of a new refractory castables and cements plan on their 35-acre heritable property near Falkirk.

Below – 08/11/1973 – Birmingham Daily Post – Craigend Refractories advert. Sales rep to cover Wales and Midlands.

Below – 20/11/1975 – The Scotsman – Craigend Refractories advert. Technical services manager to take control of a small laboratory.

c. 1979 – 1983 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that Amalgamated Anthracite Holdings were the owners.

Below – 18/10/1979 – Feel Falkirk – Kilns at Craigend Refractories. Tom Astbury.

Below – 18/10/1979 – Feel Falkirk – Kilns at Craigend Refractories. Tom Astbury.

Below – 18/10/1979 – Feel Falkirk – Kilns at Craigend Refractories. Tom Astbury.

Below – 1982 – Photograph of the Works showing packed bricks ready for transport. The photo was taken by William McCall, Maddiston.

Below – 22/04/1982 – Feel Falkirk – Kilns at Craigend Brickworks. Tom Astbury.

Below – 22/04/1982 – Feel Falkirk – Kilns at Craigend Brickworks. Tom Astbury.

Below – 22/04/1982 – Feel Falkirk – Kilns at Craigend Brickworks. Oil fired burner. Tom Astbury.

Below – 22/04/1982 – Feel Falkirk – Kilns at Craigend Brickworks. Tom Astbury.

List of all photos taken at this location by Tom Astbury.

1983 – Carbrook Mine and Craigend Works were closed and the remaining assets and trade names sold to the Burn Fireclay Co of Morpeth

6/11/1985 – Edinburgh Gazette – Notice is hereby given, in accordance with Section 36(1 )(a) of the Control of Pollution Act 1974, that an application has been made to the Forth River Purification Board by Caledon Coal Company Ltd, Craigend Brickworks, Standburn by Falkirk, for consent to discharge unspecified quantities per day of treated surface water and groundwater to a tributary of the River Avon at Grid Reference NS 9078 7370 from Bogo Opencast Site, Avonbridge.

Below – Date unknown – Catalogue held by Falkirk Museum and Archives. Craigend Refractories Ltd.

Firebrick Products.

34%-42% alumina range.

Falcon 34-36% alumina.

Falcon A 36-38% alumina.

Falcon L 36% -38% alumina.

Eagle 40-42% alumina.

Ground Fireclays

Falcon fireclay – Refractoriness 1690 – Max Service temp – 1450c.

Eagle fireclay – Refractoriness 1750 – Max Service temp – 1500c.

Quantity of the above required to lay 1000 bricks (230 x 114 x 76mm- 250kg).

Craigsill 63% alumina – very suitable for resistance for alkaline attack and volume stability as required.

Eagle 50 – 50% alumina – this brick is similar to our high-grade quality firebrick but has higher refractories and greater resistance to slag attack.

Eagle 60 – 60-62% alumina – this brick because of its high alumina content and good thermal resistance is very suited for cement and lime kiln applications.

Refractory castable

Craigend 1200 – high strength and resistant to abrasion. 40% alumina content. Comes in standard or firemix.

Craigend 1300 – general-purpose castable, alumina content 38 – 40%, comes in standard or firemix.

Craigend 1400 – medium duty castable. 42 – 44% alumina content. Comes in standard or firemix.

Craigend 1500 – high duty, low iron castable. 47% alumina. Comes in standard or firemix.

Craigend 1550 D – high-density general-purpose product, 60% alumina. Comes in standard or firemix.

Craigend 1700 – high purity low iron castable. 85% alumina content, comes in standard or firemix.

Refractory gun mix

Craigend 1200 – high strength and resistance to abrasion, 40% alumina.

Craigend 1300 – general-purpose castable, 38 – 40% alumina.

Craigend 1400 – medium duty castable, 42 – 44% alumina.

Craigend 1500 D – high duty low iron castable, 47% alumina content.

Aluminous jointing cement

Craigend air set cement – refractoriness 1690 – max service temp 1650c.

Craigend heat set cement – refractoriness 1730 – max service temperature 1650c.

Craigend hydraulic cement – refractoriness 1400 – max service temp 1300c.

Craigend super cement – refractoriness 1710 – max service temp 1650c.

Info

Below – 2017 – Photographs.

.

Below – Date unknown, but believed to be pre-1970, aerial photo of the Craigend Refractories site. Kindly forwarded by Bobby Carty aka Gerry from Rumford.

Below – The Scottish Industrial Archaeology Survey published a report in 1985 entitled ” A survey of Scottish brickmarks. During the compilation of this report in which the survey officers visited working and derelict brickworks sites, many items of interest were donated or found. Many of these items were thereafter donated to the National Museum of Scotland. The item below is one of these items. A brass stamping plate marked ‘Falcon A’.