Stevenson Bros Patent Glasgow

— 16/06/2024Found in the Glasgow area by Eddie McLean. Stevenson Bros, brickmakers, Millcroft and Polmadie Brickfields, Rutherglen Rd.; also Garscadden Brick and Tile Works, Drumchapel. . . . .

(Note – SBH – I am currently working on this page to try and confirm which posts refer to which brickworks as I think several are mixed up here!).

Garscadden Brick and Tile Works, Yoker, Glasgow aka Blairdardie Brick and Tile Works. (Note – SBH – were these works also known as the Duntocher Works – I find it confusing with regards to the references to Duntocher. Duntocher was close but it does not appear to have been the closest town to the brickworks – so was there possibly any brickworks site nearer Duntocher?). When the Garscadden Brickworks closed in c. 1916 another brickworks was erected at some point just a few meters East and also called Blairdardie Brick and Tile Works. However, it appears that several brickworks in the area may have used the name Blairdardie over the decades.

Garscadden Brick and Tile Works, Canal Bank, Bowling, Glasgow. (Note – SBH – See also the Cowdenhill Brickworks which may be the same works).

**********************************

Chapter Five – Brick and Field drain Works – Written by Eric Flack and reproduced by kind permission. It is a fascinating read.

Another local industry was the manufacture of bricks. Three of the local brickworks produced terracotta type bricks and field tiles or drains in updraught kilns from locally dug red clay. These were Horn’s which was located at the Elderslie Dry-dock at the foot of the Dyke Road and the Garscadden Brick and Tile Works, which was owned by Horn’s and latterly by Stevenson Brothers. This was located on the opposite side of the canal from Keal Drive and Avenue and had an extensive pit from which red clay was dug and then pushed by hand into wooden or metal boxes to make terracotta-type bricks in updraught kilns. They also had a clay pit on the left side of Garscadden Road towards Great Western Road. In the 1860 Ordnance Survey name book for New Kirkpatrick, it notes the following. “Blairdardie Brick and Tile Works. Robert Horn, brick keeper. This place has been used for making bricks and tiles for about 20 years. It is of a permanent nature. It belongs to Garscadden Estate the property of Mr Colquhoun of Killermont”.

Terracotta bricks are considered superior to the traditional Scottish brick due to the firing process producing higher temperatures, which produced good weather resistance. The Garscadden Brickworks latterly used coal from the Baljaffrey Pit in Bearsden, which closed in 1910. These bricks are marked “Horns” and then “Stevenson Bros Drumchapel. Glasgow”.

Stevenson’s Garscadden Brickworks closed in 1916 when the red clay deposits become exhausted. The clay pit was used as a refuse coup by Clydebank Town Council with a small fee for each load couped being paid to Garscadden Estate.

Thomas Gilmore whose father ran the Kilchattan Brick and Tile Works on Bute opened the Drumchapel Brickworks. He paid a lease of £60 per year to the Cowdenhill estate. This lease was terminated on Whitsunday 1906 due to most of the suitable brick-making material being used up. It operated between Essenside Avenue and the railway next to Drumchapel No 2 colliery. This brickwork used red plastic clay dug out of the ground at this location to produce field drains (field tiles) and terracotta bricks in an updraught kiln. After Thomas Gilmour gave up the lease the brickworks were re-opened for a short time by Kings. It is understood that the manager was killed when a railway wagon door, which he was opening, fell on him. The works shut soon after this. Gilmour’s bricks are marked “G & G Glasgow”. Other smaller brickworks exploiting the red clay was Hutton’s Brickfield run by William Hutton in 1881 and Cloberhill Brickfield. Both of these were located on the south bank of the canal between the Bard Avenue bridge and the bridge at Blairdardie Road.

Peter and Mark Hurll opened the last brickworks in the area in 1903 adjacent to the railway on land now occupied by Edrington Holdings and installed a Hoffman Continuous Kiln to produce Scottish common bricks. They installed a double-track two-foot gauge tramway to Peel Glen on the trackbed of the former Garscadden Private Tramway and built an extension of the tramway to a loading dock on the canal. An export business flourished with puffers carrying Drumchapel bricks to the Western Isles and Colerain in Northern Ireland. The tramway passed under Great Western Road adjacent to the Duntreath Avenue flyover. The brickwork used the black blaes from the mine spoil tips in the Peel Glen area. The blaes were dug out and loaded into hutches, which were then screwed down onto a slow-moving continuous steel hawser powered by a large flywheel driven by a steam engine at the brickworks.

On 27th Nov 1908 Mark Hurll, due to the lack of demand, wrote to Rev Campbell Colquhoun of Garscadden House to ask him whether he would agree to allow Hurlls a period of two or three years to make up the fixed rent of £100 per year. Mr Hurll was sad that they were loading bricks at Garscadden both in railway trucks and on the canal in order to make up the fixed rent of £100 per year. On 4th March 1910 due to the poor trade, Hurlls agreed not to re-insure the Garscadden works engine. On 31st March 1911, trade had not improved and they closed the Knightswood Brickworks. On 7th April 1911, Mark Hurlls’s salary was £300 per year and John Hurlls’s was £350. On 13th August 1918, it was noted in a letter to the NB Railway Company that the existing brickwork siding cannot be worked meantime as the cables worked from the steam plant in the brickworks which used to draw wagons into the works siding from the NB railway siding is now disused. It was also noted that there was a considerable quantity of bricks lying at the works which were at present closed down. However, the company was being pressed for delivery of bricks from the Garscadden Works for urgent orders. A small length of hutch tramway was laid from the brickworks to the NB railway siding, which could only accommodate four wagons, in order to load bricks. A nominal rent of ten shillings per year was paid to the NB Railway Company for this tramway. The hutch tramway was removed on 26th May 1921. On 20th June 1920, the unsatisfactory state of the Garscadden works due to engine trouble was noted and it was agreed to replace the steam engine with an electric motor. The works were put on a care and maintenance basis due to low demand. On 22nd September 1921, it was agreed to work as quickly as possible at Garscadden to refurbish the works with the erection of a new gangway into the mill house so as to be able to store blaes for one or two days of work. Hurlls were anticipating large orders for bricks from the new housing schemes being proposed throughout the city. On 22nd September 1921, it was agreed to re-open the Garscadden Works after hearing that the contract for the Knightswood housing scheme had been fixed. It was agreed to raise the height of the chimney by 20 feet and put a lightning conductor on it. On 24th October 1923, it was agreed to write to the London and North Eastern Railway Co and ask their permission for the construction of a footpath for the use of their workers at the bottom of the fencing from the public road on the west side of Drumchapel Station (Garscadden Road ) to end at the brickworks. On 2nd September 1924, the blaes bings at Castlehill (top of Peel Glen) were purchased for £250 with a halfpenny per ton way leave paid to Garscadden Estate. On 22nd December 1924, a blaes drier was ordered from William Rowan and Sons. On 2nd July 1925, it was agreed to supply Messr’s McDonald and Niven with 2 million bricks per year (for Knightswood) at a price of fifty-two shillings and sixpence delivered. On 3rd September a contract was agreed to supply John McCandlas of Colerain. N. Ireland with bricks. These bricks were loaded onto puffers using a loading dock at lock 36. A Proctor mechanical stoker was installed at a cost of £250 in November 1925. In May 1927 it was agreed to sell 2,500,000 bricks per year to McTaggart and Mickel at forty-seven shillings and sixpence per thousand. Sale of oldest bing in Peel Glen at two shillings per ton if it could be got. Due to demand, it was agreed to install a new Hoffman kiln at Garscadden. In June 1927 in connection with the construction of Knightswood, it was agreed to supply John McDonald with 15,000 bricks per day at a cost of fifty-two and sixpence delivered on-site.

Mark Hurll had bought South Hutcheson farm to use the coal bings that were on the land from Garscube Estate. In July 1927 it was agreed to buy South Hutcheson Farm from Mark Hurll for £2,000. The tenancy of Mr Chapman who ran it as a dairy farm with a local milk round was to continue. This farm was at the top of Ladyloan Avenue adjacent to Lochgoin Avenue. In March 1939 it was noted that Garscadden Estate had been sold to Glasgow Corporation. A going rate of £60 to £120 per acre had been the agreed rate for the sale. It was agreed to sell South Hutcheson Farm to Glasgow Corporation for £7,600 on 19th June 1939. As a result of this sale on 13th June, 1940 Hurlls were able to pay off all the arrears of preference shareholders from 1st July 1931 to 21st March 1940.

The strong demand for bricks due to new housing schemes had led to the exhaustion of the local black blaes. Efforts to secure supplies from St Flannans pit bung in Kirkintilloch by road and the transport costs to be paid by the Garscadden works were agreed. On 18th July 1939 due to the strong demand for bricks at Garscadden, it was agreed to increase working to 54 hours per week. On 16th October in exceptional circumstances. On 22nd February 1940, the Garscadden night shift was stopped due to difficulties in operating in wartime with restricted lighting. Day shift to be extended to a 54-hour week. On 10th July 1941, the supply of blaes and raw materials was causing grave concern. A lot of defective bricks which had cracked on firing were being produced due to the poor quality of the local blaise. It was agreed not to build air-raid shelters until the continuity of working was secured. On the nights of the Clydebank Blitz on the 13th and 14th of March 1941, the workers at the brickworks took shelter in the Garscadden Road School. On 18th October blaes from Garscube Colliery were being supplied at 6d per ton. The additional transport costs and wartime fuel restrictions made the production of bricks uneconomic and the works were mothballed in November 1941. Most of Knightswood and Old Drumchapel were built with Hurll’s bricks. These bricks are marked “P&M Hurll” and also “P&M Hurll, Glasgow”. Some have the “S” turned the wrong way! Thus the works closed when it proved impossible to manufacture suitable bricks from the blaes left in the local spoil tips and the high transport costs along with wartime fuel restrictions making road transport of blaes uneconomic. Some of the blaes in the spoil tips in Peel Glen had burnt and turned red due to internal combustion caused by the high level of coal matter the blaes contained. Tinkers, who used to camp in the Peel Glen area, used to go round the doors in the Bearsden and Old Drumchapel area selling loads of this material from old army lorries for use on garden paths and driveways. Similar material is ground through screens and is still used as the basis of clay tennis courts.

After the brickworks closed down in November 1941 the works were used to store ammunition. A railway loading bay was built and a barrage balloon flew over the works, which by this time were fenced off with barbed wire to a height of about 15 metres. The barrage balloon once broke its moorings and floated away!

In 1945 Hurlls wrote to the Garscadden Estate factors regarding re-opening the brickworks and using blaise from a bing at Castlehill. Garscadden Wood. In 1951 because of a shortage of home-produced bricks required in the construction of the new housing estate in Glasgow, the Corporation of Glasgow Housing Committee approved the purchase of two shipments of Belgian wire cut bricks. A total of 400,000 bricks were bought at a cost of £13.50p per 1,000 delivered to the building site. The total cost was £5,4000. The cost of these bricks was almost double the cost of home-produced bricks. Due to the scarcity of building bricks, every available brickworks in Scotland was working flat out to meet demand. In 1951 the Alexandra Transport Company (part of the Tilcon group) bought the Garscadden Works. Refurbished the Hoffman kilns at Hurll’s Brickworks and re-opened the brickworks. For a time they used some local blaes from the mine spoil tip at Castlehill adjacent to Gascadden Woods next to Bearsden Golf Course. However, most of the blaes was brought in by lorry from the Cadder Area. The bricks were used in the construction of Drumchapel. In 1957 the brickwork closed, and the land was cleared and is now occupied by Edrington Holdings. The only traces of the mining industry left in the Drumchapel area are the locally produced bricks with the name of P&M Hurll, Stevenson, Horne, Gilmour marked (G&G), King and in the 1950’s ATC on them. So look out for these. There is an old coal pit air ventilation shaft still visible, on the left-hand side, at the top of Peel Glen road. Also on the left side of Peel Glen Road at its junction with Bearsden Road are the remains of an old pit. On the left-hand side at the foot of Peel Glen Road facing a mine adit can still be seen. This adit drained water from the pit at the top of Peel Glen. The foul water from it, heavily polluted with red iron oxide, was drained across the Peel Glen burn in a pipe into a small drain which led to the Cleddans Burn. Part of this drain is still visible. The residents of the old grey stone miners row in Peel Glen and the residents of the Drumchapel Row used the Peel Glen burn as a clean water supply. It was thus called “the healthy burn”

One interesting thought is that the iron plate Railway Bridge in Garscadden Road erected in 1858 and manufactured by Sommervail in the Dalmuir Ironworks from iron plate supplied by Bairds Ironworks could be made from locally mined iron! During the general strike in 1926 people from Glasgow and Clydebank used to push old prams to the pit bings and search through the colliery waste for any lumps of coal.

Subsidence associated with this mining activity is a known problem in the area. On Monday, November 7th 1994 a drilling rig attempting to seal the Garscadden No3 pit shaft discovered by Glasgow City Council in September at the junction of Lochgoin Avenue and Achamore Road crashed through the tarmac in Achamore Road and fell into the shaft which was estimated to be some 60 metres deep. In November 2002 the Coal Authority were called in to cap the mineshaft of Drumchapel No1 pit which had caved in causing a section of the gardens between numbers 3 and 7 Drumchapel Gardens to disappear into a fairly large hole which proved to be about 90 metres deep!

*********************************

R & W Horn ran a brickworks just south of Lock 35 at Drumchapel on the Forth and Clyde canal. The works were taken over by Stevensons of Drumchapel Glasgow. The works closed in 1916. They used “red” clay from an open clay pit. R & W Horn also had a small brick-making kiln where the Elderslie dock is – part of the BAE systems yard now. Formerly Yarrows of Scotston. It also used “red” clay. Garscadden Brick and Tile Works run by Robert & William Horn of Yoker (died 1875 and 1896 respectively) and latterly run as Blairdardie Brick & Tile Works by the Stevensons at Lock 35 on the Forth and Clyde Canal closed in 1916. Source

********************************

Below – Abridgements for 3 wills relating to William Horn, Robert Horn and James Horn. The first dates are the date of the will being open.

Robert Horn, 13/07/1875 Brick and tile manufacturers, Garscadden. Resided at Thirdpart Mill, Parish of New Kilpatrick, Dunbarton County of Dumbarton Sheriff Court SC65/34/20.

Possible family connection Lieut Alexander Duncan Campbell King. Died 24/05/1915 – son of Robert King, Brickmaker, Torphichen.

*********************************

Source – Bell, Hornsby & Co. – Mason and brickwork contractors – Bell, Hornsby & Co. were a building and contracting firm, and one of many brick manufacturers in the Glasgow area. From the 1860s to the 1890s, local brick was widely used for factories, and for the internal and rear walls of stone-faced commercial and domestic buildings). Of the original partners, Alexander Hamilton seems to have been the longest established, manufacturing bricks at Lilybank off Eglinton Street, on the south side of the city, from about 1852. He expanded into tile making, operating from a second brickworks at Strathbungo in 1858, before becoming a ‘silent partner’ in Bell, Hornsby. Another partner, Robert Bell, possibly ran a bricklaying firm in South Wellington Street c. 1857 (He is not to be confused with the wealthy Wishaw and Broxburn industrialist of the same name, who was also a brickmaker). Other partners were John Thomson Hornsby and Alexander Whitelaw, a Greenock based builder.

The firm of Bell, Hornsby first appears in the Glasgow Post Office Directory for 1864 as ‘brickmakers, builders and contractors’, based at Hamilton’s premises. Bell, Hornsby and Hamilton at first all lived beside their works, before moving elsewhere. They shed a partner in 1868 when Whitelaw chose to continue on his own.

By 1875, the partners had taken over Polmadie Brickworks, Rutherglen Road, with its clay pits nearby at Mallsmire Burn. Brickmaking was a seasonal activity; since clay digging was impossible in winter when the ground froze, and good weather was important for initial drying. Rather than pay for the upkeep of draft horses over winter, the brickmakers, including Bell, Hornsby, sold them off. As a supplementary activity during the closed season Bell, Hornsby erected one or two blocks of tenements at a time (probably using their own bricks) in the fast-growing working-class area of Polmadie. Of the 46 tenements built there, ‘Robert Bell, house factor, and John Bell, mason’ were proprietors, and therefore the likely builders, of five.

In 1883, Bell, Hornsby were prosecuted for a breach of the Factory Act: ‘Inspectors were very particular in enforcing the law with respect to the employment of young girls [under 16 years] in brickfields’. By the time Robert Bell retired in 1886, the firm was running an additional brickworks at Blairdardie, which was beside its own clay pits at Garscadden, and another at Govan. The business was continued into the 20th century by John Hornsby Junior, after his father’s retirement in 1896. Since the late 1860s, it had been based at 197 Pollokshaws Road, and it continued to operate from here until at least the 1920s.

**********************************

“Both sides of the burn, the story of Yoker” was published in 1966 … Yoker at one time provided the labour for no fewer than three brickworks all of which were fully engaged in the provision of material for the great building schemes in Clydebank and Yoker at the end of the last century (19th).

Two of these, King’s at Blairdardie near the children’s hospital and Mark Hurrel’s (Hurll’s) near the Boulevard west of the police station were based on the blaes or coal waste of Peel Glen and a site near Chapman’s Farm. The blaes or red shale was milled with water to form a clayey material which was then moulded in wooden boxes before being fired in brick kilns heated of course, by coal mined locally.

The third works, Horne’s, (Horn), stood near the Clyde on ground facing Elderslie Bar. It produced clay bricks, which of course, were stronger, weather-resistant and in every way superior. Barclay Curle’s Dock now occupies the site.

23/10/1857 – Glasgow Herald – Drain pipes, tiles and bricks warranted of the best quality and ready for shipment, at the Garscadden Brick and Tile Works, on the canal bank, near Bowling. Orders to be addressed to Archibald McInnes at the Works by Yoker.

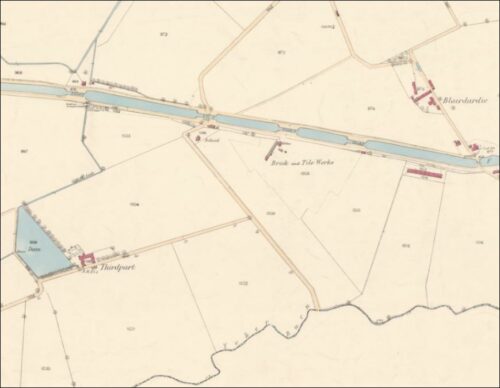

Below – 1859 – Garscadden Brick and Tile Works (Note – SBH – Although they appear not to have been named as such on the map in 1859 and may have been known as Blaidardie Brick and Tile Works at this point! – Note also ‘Thirdpart Farm where the Horns resided ).

1860 – ScotlandsPlaces – Blairdardie Brick and Tile Works. Robert Horn. This place has been used for making bricks & tiles for about 20 years. It is of a permanent nature. It belongs to Garscadden Estate the property of Mr Colquhoun of Killermont.

07/02/1861 – Glasgow Herald – Ploughing match at Dalmuir Farm occupied by Robert Morton … After the competition, upwards of sixty gentlemen sat down to diner in Mr Alexander Reid’s tavern, Dalmuir including J. Easton, T. Thyne, A. McInnes, Garscadden Tileworks.

1869 – Bell Hornsby & Co & Co, Blairdardie, New Kilpatrick.

1869 – Bell Hornsby & Co. 197 Pollokshaws Rd; Brickfields, Polmadie, Glasgow, Langlands, Govan, Blairdardie, Duntocher.

1873 – 1874 – King & Garruth – Brickmakers, Blairdardie Works by Duntocher, Glasgow. Office 150 Hope Street.

23/08/1873 – Glasgow Herald – Dumbarton – Warning to brickmakers – Robert Horn, brickmaker, Garscadden was yesterday charged before Mr Thos. Thomson and Mr Robert Buchannan, at a Justice of Peace Court, with having employed two girls under 16 years of age in his brickwork and in violation of the Factory Act. He pleaded guilty and was fined in the reduced penalty of 10s for each offence.

23/05/1874 – Paisley Herald – Death – At Thirdpart Mill Farm on the 21st inst, Robert Horn Esq, late of Garscadden Brick and Tile Works.

1874 – 1875 – King & Co, brickmakers; Works, Blairdardie, by Duntocher; office, 150 Hope Street.

1875 – 1876 – King & Co, brickmakers, Blairdardie.

1878 – Robert A King, agent for contractors, builders, and quarry masters plant of all kinds, new and secondhand, for sale or hire; agent for Plann Fire Clay Works; plant stores, 130 Waterloo Street; fire-clay goods depot, Cook street station; house, 10 Walworth Terrace, Kent road.

Robert A. King, brickmaker, Blairdardie Brickworks, by Duntocher; office, 130 Waterloo Street.

1878 – 1879 – Blairdardie Brick and Tile Works, by Duntocher. William Hardie Managing partner, Blairdardie.

1880 – 1881 – Blairdardie Brick and Tile Works, by Dunochter.

1880 – 1881 – Robert A King 130 Waterloo Street – Agent for Jospeph Cliff & Son, Wortley.

1881 – 1882 – Blairdardie Brick and Tile Works, by Dunochter.

1883 – 1885 – Invoices – R & W Horn, Garscadden Brick and Tile Works by Duntocher.

02/09/1885 – Scotsman – Breach of the Factories Act – Yesterday, before Sheriff-Substitute Cowper in the Dumbarton Sheriff Court, R & W. Horn, Garscadden Brick and Tile Works, New Kilpatrick, were charged at the instance of Mr J. S. Maitland, H.M. Inspector of Factories, with- (1) employing two boys without having certificates of fitness by the certificating surgeon of the district; and (2) with neglecting to keep the proper forms prescribed by the Act-viz, a register of young persons employed by their works. Both offences were admitted, and the sheriff imposed penalties amounting to £1, 17s. 6d. including costs, or fourteen days imprisonment.

1886 – Horn Robert & William, Garscadden & Cowdon Hill, Glasgow. p 416.

1886 – Robert and William Horn, Garscaddon and Cowden Hill, New Kilpatrick.

1886 – Bell Hornsby & Co, brick and tile maker, Blairdardie p.416.

1893 – William Horne, Brick and Tile Maker, Yoker (note spelling or Horn).

Below – 1894 – Garscadden Brick and Tile Works.

1903 – Robert and William Horn, Garscadden, Yoker, Glasgow and Rbt and Wm Horn, Garscadden and Cowden Hill, New Kilpatrick, Glasgow.

12/09/1908 – The Scotsman – New company. Peter and Mark Hurll Limited, Glasgow (private company), to purchase and take over the business of brick manufacturers carried on at Glasgow, Garnqueen, Glenboig, Knightswood and Garscadden Works near Glasgow. Capital £50,000 in 25,000 pref shares of £1 each and 25,000 ordinary shares of £1 each.

04/06/1909 – Milngavie and Bearsden Herald – Drumchapel. Firms overlook. In Dumbarton Sheriff Court last Friday an employee. representing Stevenson Bros., brick and tile merchants, Drumchapel, was charged with having failed to leave posted up at their Drumchapel Quarry an extract of the Quarries Act, 1894. The Fiscal stated that the offence had been reported by an Inspector of Mines, and probably a small fine would meet the case. Sheriff P. J. Blair imposed a fine of 10s, the option being three days’ imprisonment.

21/01/1910 – Milngavie and Bearsden Herald – Local Builders Affairs. William Stevenson, builder and brickmaker and trading inter alia as Bishopbriggs Building and Joinery Company at Bishopbriggs, Glasgow, examined in bankruptcy before Sheriff Balfour in the County Buildings, Glasgow on Monday. Bankrupt stated, in answer to Mr Walter Neilson, trustee, that he started business on his own as a builder in 1874. He took over the Bishopbriggs Company about October 1907. The capital put into that business was all borrowed, and he had since repaid the loan. He was also interested in the firm of Stevenson Brothers and in the Bishopbriggs Brick Company, he had 1000 shares and was a director. These shares had been transferred to the bank in respect of an overdraft on behalf of Stevenson Brothers. His holdings in South African and other companies had also been deposited with the bank against advances. He had an interest in a large number of properties and would supply a note of all transactions of such. The value of the furniture belonging to him in his house at 55 Dixon Avenue was £28 odds, and he had also some furniture of little value in a house of which he was a tenant at Rothesay. Bankrupt accounted for his insolvency owing to the depreciation which had taken place of late in the value of the property. The Bishopbriggs Joinery Company had been carried on at a loss. By a creditor – He had been sequestrated before, in the spring of 1889, and got a discharge. He was short of money for the last three or four years. His loss on the brick and joinery business he estimated at about £2000 and the losses on his stock exchange transactions would come about the same amount. The examination was adjourned.

1914 – The Garscadden Brickworks were closed prior to this time as this map shows the Blairdardie Brick and Tile Works situated just East of where the Garscadden Brick and Tile Works were previously located. It is believed the Stevenson Brothers were the operators at the time of closure.

(Note – SBH – Note if Garscadden Brickworks closed c. 1914 then the following references to the Garscadden Brickworks must refer to a different location but I am uncertain as to exactly which one).

24/08/1935 – Coatbridge Leader – Big order for Glenboig. Two hundred thousand bricks. Winters work assured for villagers. Messrs P. and M. Hurll Ltd., firebrick manufacturers, Gartliston Works, Glenboig announced this week that they have received an order from an overseas corporation for the supply of almost 200,000 bricks of various sizes. This latest order, it is understood, will ensure employment for many men and women throughout the winter. Contracts for ironworks in the English Midlands and Belgium have resulted in the Gartliston Works being at full pressure for some time past. It is interesting also to know that the Glenboig firm’s works at Garscadden, where building bricks are manufactured, have also been extremely busy. To cope with the rush of orders, indeed, a nightshift has had to be put on, and more than 300,000 bricks are being despatched every week for building schemes in Scotland and Ireland.

1948 – Kenneth Sanderson states in his book The Scottish Refractory Industry 1830 – 1980 – “Hurll owned building brickworks and associated clay pits at Garscube, Maryhill, Knightswood, Yoker and Garscadden, all in the Glasgow area. Garscube made sewage pipes on an early Pullen and Mann machine, using fireclays sent from Glenboig. The British Clayworker Magazine of November 1984 reported the discovery of a blue Staffordshire type of clay in the Carluke area, Lanarkshire, which was also used at Garscube for a period. The Garscube and Knightswood Works had closed by the early 1930s but the Garscadden Works continued until 1948 when it was leased to Keir and Cawder”