Burnfoot Tileworks, Ochiltree, Ayrshire aka Ochiltree Tileworks

Special thanks go to SJ and Will Galbraith, Pant Farm, Mauchline, Ayrshire for their information and goodwill which assisted greatly in the compiling of this post.

Canmore – A typical drainage tileworks, still in operation, with an L-plan range of louvred single-storey drying sheds and two kilns, one of them is circular, with a square-section brick chimney (1976)

1825 – 1881 – After James Taylor’s death in 1825 there seemed no possibility of finding a tenant for the Pottery, so Lord Bute turned to Robert Taylor (James’s son) to fill the post. Robert was aged 22 when he took over the running of the Pottery and ran the Pottery well. However, this was a slack period as trade in general at an all-time low. The Pottery was advertised for lease again in 1831, but as no tenant came forward Robert again offered to take the lease. Apart from operating the Pottery, Robert was also involved in a Tilework on farmlands at Burnfoot, Ochiltree.

1835 – The Burnfoot Tilework, which was established by the Marquis of Bute, Lord John Crichton Stewart, in 1835 with the help of Robert Boyle of Drongan, was operated very briefly by Robert Taylor. The production was also carried out at one point by the Edgar family. Shortly afterwards a tileworks operated close by at Hillside Farm. Alexander Hamilton took over Burnfoot Tileworks in 1838 and introduced the process of manufacturing firebricks on a commercial scale and built high-temperature kilns to utilise the local fireclay deposits. Experienced tile burners were required to be employed at Burnfoot, two are named as Francis McDonald, a brickmaker from Kilmarnock and the other being called William Freeborough from the tilework at Wellhill.Unknown source.

1838 – The Cumnock Pottery passed into the hands of Alexander Hamilton of Mauchline who ran it in conjunction with the Burnfoot Tileworks.

1839 – After the death of her husband Alexander, Mary Hamilton was to influence the outcomes of the business at Cumnock with regard the management of the pottery (Note – SBH – Did this include the tileworks at Burnfoot). Unknown source.

14/03/1844 – Ayr Advertiser – Adjourned meeting of the Road Trustees for the District of Ayrshire … At the above meeting, the Trustees will consider and determine upon the expediency of erecting the following check and side-bars and exacting toll duties thereat viz … 4. Check-Bars at the Turnpike Road from Ayr by Cumnock to the confines of the County. (1st) to the West of the Parish leading from said turnpike road, by Palmerston and (2d), to the East of the road leading from said turnpike road to the Burnfoot Tilework, both in the Parish Ochiltree.

1851 – 1852 – James McClownan, Tilemaker, Ochiltree, Ayrshire.

1856 – James McGavin Nicol was in control of Cumnock Pottery. He also continued the production of bricks and tiles at Burnfoot Tileworks.

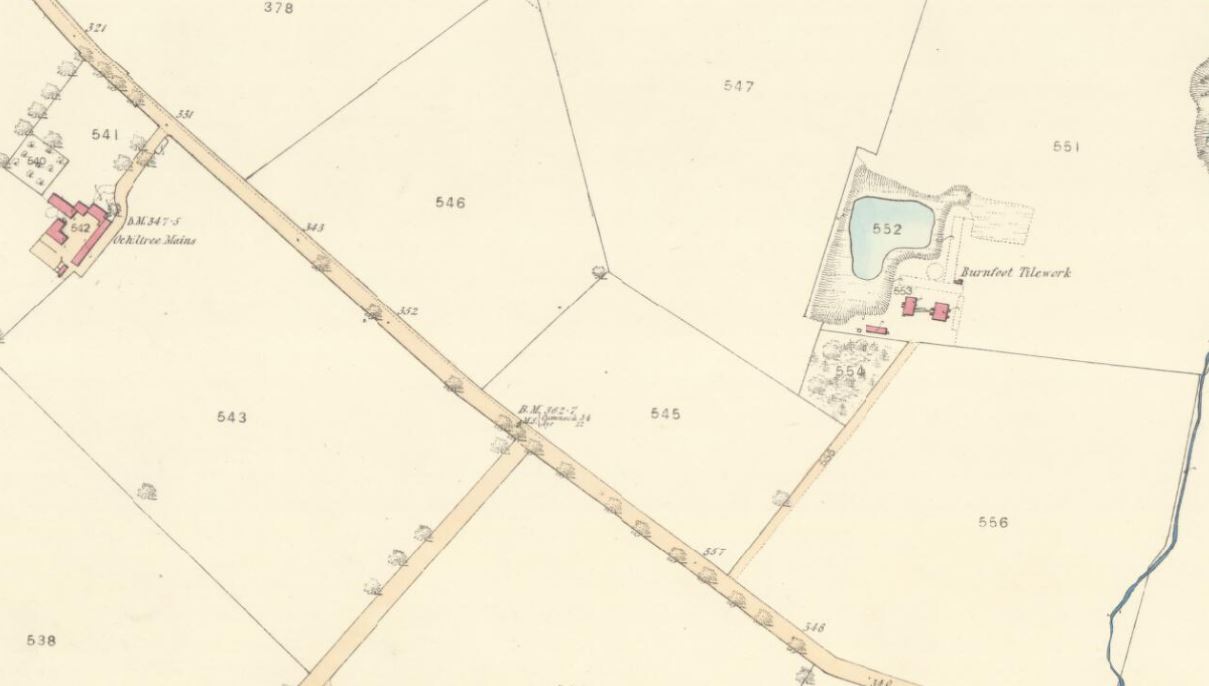

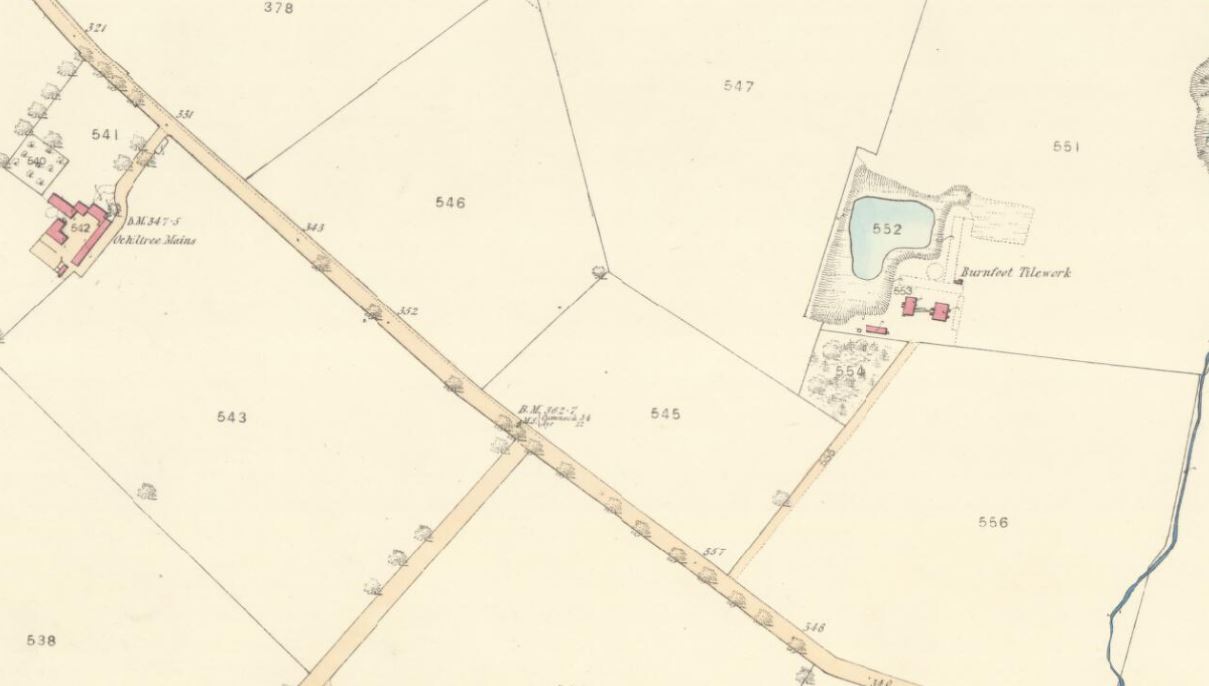

Below – 1857 – Burnfoot Tileworks, Ochiltree.

Below – 11/07/1863 – Ayrshire Express – Farms on the Dumfries Estate to be let – The farm of Ochiltree in the Parish of Ochiltree, as at present possessed by George Paterson, extending, according to Ordnance Survey, to about 190 Acres Imperial, exclusive of ground occupied by Burnfoot Tilework, and a feu to be given off. This farm is situated close to the village of Ochiltree and contains some first-class land. About 135 Acres have been drained. Entry at Martinmas …

1867 – Hugh Meikle, Brick and Tile Works, Ochiltree, Cumnock.

23/11/1872 – Ardrossan and Saltcoats Herald – Deaths – John Todd Dickie aged 20 years, youngest son of the late John Dickie, tile manufacturer, after a lingering illness, borne with much Christian meekness at Burnfoot Tileworks, Ochiltree on the 20th inst.

1886 – James McGavin Nicol, brick and tile maker, Ochiltree and Cumnock, Ayrshire.

19/07/1890 – North British Daily Mail – Industries of the West of Scotland. No 10. Old Cumnock … Cumnock Pottery Co … The same firm have Burnfoot Brick and Tile Works at Ochiltree, employing 14 hands and Wellhill Tileworks at New Cumnock employing 10 hands. They also have a lime works at New Cumnock producing the celebrated Benstone lime and a small colliery at the same place in which 9 men are employed …

1893 – James M Nicol, brick and tile maker, Ochiltree, Ayrshire.

Below – 1895 – Burnfoot Tileworks, Ochiltree

24/03/1905 – Ardrossan & Saltcoats Herald – Cumnock – lecture to farmers … now that the new tile works were being erected in Ochiltree and Cumnock parishes if the landlords would give them a supply of tiles they could make their lands better adapted for improvements …

Below – 1908 – Burnfoot Tileworks, Ochiltree.

19/12/1921 – Invoice – John S Duncan, brick and tile manufacturer, Burnfoot, Ochiltree. Burnfoot Tileworks, Ochiltree. Estimates on application. TA – Tile, Ochiltree. Drain tiles, bricks, draining, road-making, excavating etc.

22/05/1931 – Dundee Courier – East Fife Show winners – Poultry, Utility classes – A.O.V Cock … 4th, Wm Duncan, Burnfoot Tileworks, Ochiltree.

Below are some working scenes from the tileworks.

Below – Wide shot of the works showing, house, kiln, drying racks and stack of tiles

Below – Clay drainage tile extruder machine.

Below – Green tiles air drying.

Below – Tiles being sealed into kiln ready for firing.

01/05/1937 – The Scotsman – New Scottish Companies –

- Ochiltree Tile Works Limited, Ochiltree, Cumnock. Private company to carry on the business of makers of drain pipes, bricks and other clay goods etc. Capital £5000 in £1 shares. Subscribers R.W. Martin, tile manufacturer, Midsands, Racecourse Road, Ayr and T.B. Gibson, tile manufacturer, Milton Bank, Carluke.

- T.B. Gibson and Company Limited, Milton Tileworks, Carluke. A private company with objects and subscribers as in previous company. Capital £10,000 in £1 shares.

02/07/1943 – Carluke and Lanark Gazette – Death of Mr Robert W Martin – The death occurred on Tuesday at a nursing home, Ayr, of a member of a well known Carluke family in the person of Mr Robert W. Martin, Midsands, Racecourse Road, Ayr, youngest son of the late Mr Hugh Martin, engineer, Carluke. Mr Martin was identified with the firm of Hugh Martin & Sons until 1927 when he went into business for himself as a tile manufacturer at Ochiltree. Latterly he became interested in the firm of Gold & Co., tile manufacturers, Law. He leaves a widow and one son, who is at present serving with the R.A.F

1951 short film – no commentary – The manufacturing processes involved in producing clay tiles at Ochiltree Tileworks

Shotlist: Credits (.23); General views of the exterior of the tile works (.30); Shots of tiles stacked up in the yard (.34); Clay deposits near Ochiltree, Ayrshire, are suitable for making drainage tiles. General views of men digging up slabs of clay and loading them onto a wheelbarrow, which is then taken away along a plank (1.28); A skip is sent down on rails to the workforce from a building about 100 yards away. It is filled with clay and pulled back up by rope (2.02); Lime is mixed with the clay to make it more plastic. Lime is shovelled onto clay which is put into a mixer (2.25); After mixing the clay is ready to be moulded. Pieces of clay are fed into a machine (2.35); The clay is shaped by being fed through a template. One man marks out a template, then it is attached to the machine and the clay is forced through, forming tubular lengths (3.01); More shots of loading clay into machine and then at the other end as the lengths of clay are passed along conveyor where it is then sliced into short lengths (3.41); The shaped lengths are stacked for drying. Men use a three-pronged fork-like instrument to pick up the lengths and stack them onto shelves (4.27); Shot of the wall of the yard, lined with shelves of clay tubes (4.35); The dried lengths are hardened by firing in a kiln. Kiln is loaded with barrowfuls of dried pipes (5.20); The door is bricked up and sealed with a layer of cement and mortar (6.21); The fires are stoked (6.41); Shots of kiln with all chimneys belching out smoke (6.52); After three days the wicket or door is opened. The mortar is chipped away and the bricks pulled out (7.32); The tiles are removed when cold. Man loads barrow with tiles from the kiln and stacks them up in the yard (8.05); A lorry, marked on the tailboard with “Drain with Ochiltree Tiles”, is loaded with tiles (8.10); Long shot of the works as lorry pulls out of the gate with its load (8.30); The End (8.34)

Below – 1962 – William Duncan, Manager standing at the wicket of the rectangular updraft kiln. Williams son Robert Duncan also worked at the tileworks up until it closed.

Below – 1975 – 1976 – An aerial photo of Burnfoot Tileworks. The round kiln (centre) is of a downdraft design. The rectangular kiln (centre left) is an updraft kiln. The small building below the rectangular kiln is the office. The 3 buildings at the top of the photo are from left to right – A building housing the Pugmill then the restroom centre with the chimney and the toilet block is to the right.

1982 – Works closed.

You will note the cottage at the works – see the last photo – The cottage still stands today – 14/06/2015.

.

Below – Unknown date – Clay being dug by hand – possibly at Pant Farm, Mauchline

Below – 3 pronged wooden hand tool for lifting clay drainage tiles, 3 at a time (Note – SBH – I want one!)

.

Below – Lorry transporting clay tiles with the slogan on the tailgate ” Drain with Ochiltree Tiles”.

Source Cumnock History Group … After James Taylor’s death in 1825, there seemed no possibility of finding a tenant for the Pottery, so Lord Bute turned to Robert Taylor (James’s son) to fill the post. Robert was aged 22 when he took over the running of the Pottery and ran the Pottery well. However, this was a slack period as trade in general at an all-time low. The Pottery was advertised for lease again in 1831, but as no tenant came forward Robert again offered to take the lease. Apart from operating the Pottery, Robert was also involved in a Tilework on farmlands at Burnfoot, Ochiltree.

In 1838 the Cumnock Pottery passed into the hands of Alexander Hamilton of Mauchline who ran it in conjunction with the Burnfoot Tileworks. Alexander modernised the Pottery and continued making the ornamented ware developed by Robert Taylor. He extended the works which had not changed since they were built nearly 50 years before. Alexander died in 1839 aged 55 – just months after the Pottery was re-opened. The Pottery was run by the Hamilton Trustees until 1856.

***************************************

Below – The following information is from an unknown source.

John Smith b. 20/09/1837 at Ochiltree. Died 10/03/1887 in New Cumnock.

1837 – Born to David & Mary at Barlosh, Ochiltree.

1859 – Agricultural labourer of Ochiltree, Ayrshire – marriage to Catherine.

1861 – Age 23, tilemaker, living in Ochiltree (High St) with wife Catherine and 2 eldest children.

1871 – Census: age 33, foreman brickmaker at Wellhill Tileworks, New Cumnock, living with wife Catherine and 4 children.

1876 – Brickmaker at Wellhill Tileworks, New Cumnock.

1881 – Census: age 43, living with wife Catherine and 5 children, including Barbara, at Burnfoot Tileworks, New Cumnock.

1887 – Died, age 49 at Burnfoot Tileworks, New Cumnock.

1893 – James M Nicol, Brick and Tile Maker, Ochiltree, Ayrshire.

************************************

The clay used by Ochiltree Tileworks to manufacture tiles appears in the main to have been extracted from 2 locations on Pant Farm, Mauchline. The following photos show the old clay pit now waterlogged and the last claypit which was actually filled in by Wills father to prevent the Council commandeering it for a refuse dump which apparently was the plan.

Below – The original claypit

.

Below – The ‘last’ claypit – to the left of the road in the first photo below.

.

Below – The remains of 2 clay workers cottages situated between the 2 claypits at Pant Farm, Mauchline

Below – A lead box time capsule found while working on the Clay Workers cottages above – it was located behind a cornerstone.

Below – Found within the above time capsule was a lead plate bearing the inscription ” Erected by Sir Willm Miller Bart, and stone laid upon Wednesday the 19th Dec 1849″

Below – Pant Farm, Mauchline supplied the raw clay to the Ochiltree Tileworks approximately 3 miles away.

A visit to Pant Farm, Mauchline recovered the following examples of drainage pipes which are believed to have been made at the Barskimming Tileworks or made at the Ochiltree Tileworks.

A ribbed tile with a flange on each corner which means it can lie flat on any side although the opening is oval-shaped. 12″ long x 2¾” x 2½”

.

.

.

.

Below – Almost round tile but not quite. 11″ long x 3″ 2½”

.

Below – Flat bottomed oval tile – 14″ long x 4″ x 3¾”

.

.

.

Below – Almost round tile but not quite. 12″ long x 4¾” x 5″

.

Below – Flat bottomed almost round tile. 12″ long x 5″ x 4¾”

.

********************************

From an unknown book of unknown date which features Ochiltree – Dickie: The tilework was for many years carried on by Mr Dickie, a brother in law of Mr A.B. Todd, poet, novelist, journalist, auctioneer, Sheriff’s Officer, farmer and tile maker. The Dickies were all intellectual and hard working. Matthew and Andrew became Ministers in the United Presbyterian Church, the former at Sanquhar and the latter at Huntly and both retired in 1917. John died in 1872 … John Duncan carries on the tilework …

********************************

The Cumnock Pottery – James Taylor on his arrival at the pottery was put to task in carrying out a geological survey of the minerals available on the estate of the Earl Patrick of Dumfries. In 1792, Mr Taylor was the manager of all operations in extracting lime, coal, black lead (wadd), ironstone, clay and lead. Also included was the mining of Antimony. A pottery producing ‘brownware’ had previously been set up in Cumnock. A rare deposit of white porcelain clay had at various times, been worked.

The occurrence of graphite at Craigman was responsible for the pottery’s manufacture of refractory crucibles when combined with local fireclay. Production was from the early 1780s. The local fireclay deposits provided the material from which firebricks were manufactured and these were required for building and repairing the potter’s kilns.

Taylor was also responsible for the manufacture of pencils on a limited scale up to the 1840s. Pantiles and a limited number of wheel-thrown drain tiles were made at the pottery also.

When James Taylor died in 1825, the management of the pottery is leased to his son Robert, then aged 22. As a result of a depressed market, he only ran the factory for 6 years then the lease was advertised. As there was no uptake on the pottery lease it reverted back to Robert. Robert was also involved in the establishment of a tilework in the Parish of Ochiltree at Burnfoot.

From 1838 the pottery was under the control of Alexander Hamilton of Mauchline and this was combined with the Burnfoot Tileworks to form a new company. In the same year, Mr Hamilton proposed opening a new tilework at Benston. This was called Wellhill Tilework. In addition to this, a clay field was also leased in the Parish of Old Cumnock. The final period of production of the pottery was from 1886 to 1920 with control of the company being provided by the stepson of James McGavin Nicol, Mr David Dunsmor … Unknown source.

*******************************

.

.

.

.