Carluke Tileworks, Law Junction, Carluke aka the Waterlands Tileworks.

Canmore

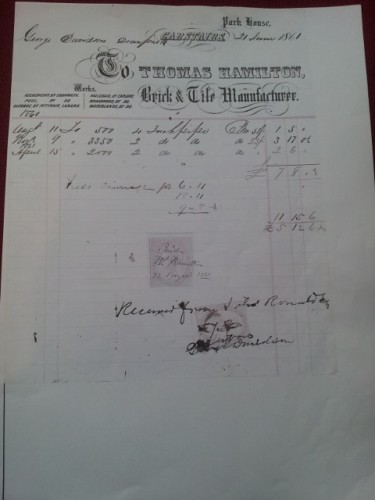

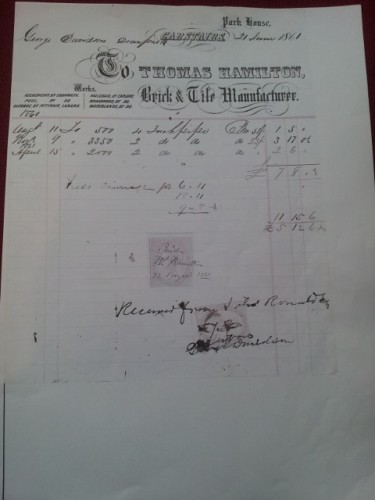

Below – 21/06/1861 – Invoice – Thomas Hamilton, brick and tile manufacturer. Park House, Carstairs.

Works Auchengray by Carnwath.

Pool by Carnwath.

Glenboe by Pittinain Lanark.

Hallcraig, Braidwood and Waterlands by Carluke.

500 4″ pipes – £1 and 5 shilling.

3350 2 inch pipes – £ and 17 shillings and 1/2d.

2000 2 ” pipes – £2 and 6 shillings.

1868 – Invoice – Thomas Hamilton, brick and tile manufacturer, Parkhouse, Carstairs. Works – Auchengray by Carnwath and Pool by Carnwath and Carmichael by Lanark and Braidwood by Carluke and Waterlands by Carluke and Corehouse by Lanark. The reference to Parkhouse, Carstairs maybe Mr Hamiltons residence and office?

1908 – In the ‘Wanted’ section was the following notice: Two good spades men and one experienced burner. Apply Thomas Fleming, Waterlands Tileworks, Law Junction.

Below – 07/06/1909 – The Scotsman – Divorce proceedings involving David Just Gold, brick and tile manufacturer, High Street, Carluke. ( Note – SBH – I have added this just in case David Gold was a business partner of Andrew Gold)

27/02/1915 – Carluke and Lanark Gazette – Operations in connection with the starting of new colliery have been commenced in Law district by Messrs Wilsons & Clyde Coal Co., Ltd. The new shaft, which will be about 35 fathoms deep, is to be sunk on the opposite side of the road from the Tileworks of Mr N. Gold at Waterlands, the Old Wishaw Road … It may be interesting to know that the upper seams of coal which this new colliery will work were worked by colliery on the opposite side of the road about forty years ago. This colliery, which was known as ‘Waterlands Pit’ was situated on that area of ground occupied by the Tileworks of Mr Gold and was the property of Messrs Loudon & Miller …

14/08/1920 – Dundee Courier – New Scottish company. Gold and Co. Capital £5000 in £1 shares (private company), to carry on the business of colliery, quarry, claywork, pottery, tilework &c owners or lessees.

21/09/1920 – Gold and Company Limited (in liquidation). Notice is hereby given, in terms of Section 195 of the Companies (Consolidation) Act, 1908, that a general meeting of Gold & Company Limited, Carluke Tilework, Law Junction, in liquidation, will be held in the office of the liquidator, 2 Candleriggs, Alloa, on Saturday, 23rd October 1920, at 10 a.m., for the purpose of receiving an account showing how the winding-up has been conducted, and the property of the company disposed of, and giving any explanations thereof; and also determining, by resolution, the manner in which the books, accounts, and documents of the company shall be disposed of. J. Reed, Liquidator. Alloa, 21st September 1920.

1929 – Gold & Co (1920) Ltd, Carluke Tileworks. Registered office 112 Bath Street, Glasgow.

1931 – 1932 – Gold & Co (1920) Ltd ( Field drain tiles), Registered office 112 Bath Street, Glasgow. Phone Douglas 3403.

1939 – 1940 – Gold & Co (1920) Ltd, Carluke Tileworks, Law Junction.

1942 -1943 – Gold & Co (1920) Ltd, Carluke Tileworks, Law Junction.

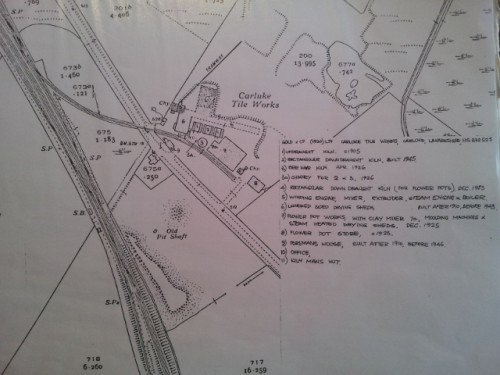

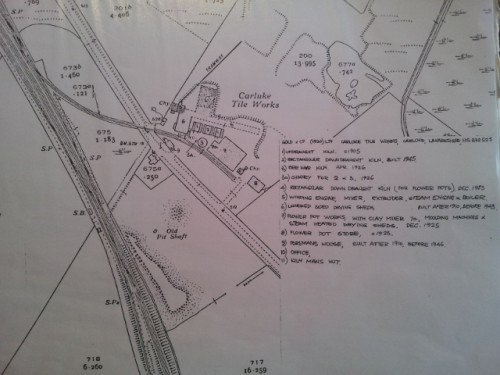

Below – 1954 – Waterlands Tile Works. The blue cross marks the position of the Law Junction Tileworks and the Carluke Tileworks aka Waterlands are underlined by 2 blue lines.

04/02/1975 – An entry in the Edinburgh gazette making reference to a change of directorship for Gold & Co (1920) Ltd, Carluke Tileworks, Law Junction.

**********************************

The following entries are recorded by the Carluke Parish Historical Society as being extracts from ‘James Blake’s notebooks … they reference Mr Gold and Waterlands.

David Crawford 23/01/42 – 7 men last year £350 extra, Coal £150 more. 2 horses £100 extra in 1 year. Oil £500 extra. Total increase £700?

20 kilns against normal 35 – 36. Output about 360,000 all sizes against 648,000 normal.

J Smellie – 40 kilns against 50 – 60 normal. Output 400,000 against 550,000 normal.

Castlehill drainers find a field of clay at Orbiston, Bellshill on Lawmuir Farm – old works here.

##

Tileworks and Clay and Clayfields.

Andrew Gold 1860 with Loudon & Russell.

Gibson about 1885.

Alex Braidwood made hollow blocks.

Castlehill drainers find a field of clay at Orbiston, Bellshill on Lawmuir Farm – old works here.

From an advert in Glasgow Herald – John Miller, Woodhead, Bothwell – clay over 80ft which J Loudon did not appear to think much of his field.

J Loudon also looked at a field on John Watson’s (coal master) ground at Neilston – this field was thoroughly pitted by United Collieries.

##

Gold’s Tileworks.

Started about 1860. Andrew Gold along with Loudon and Russell at a site near Low Crossing.

Gibson took adjoining clay field and Gold had later to move across the road to Law Village.

He took Waterlands clay field about 1904 and commenced making bricks about 1906.

Company formed in 1918. 21/06/1918 – capital 11,000 founders share of 10 shillings – £5500 Fully paid 8900 ordinary shares of £1 = £8900. Total £14,500.

Lease 30 years from? 1919.

The company wound up on 22/01/1920 and a new Company was formed called Gold & Co (1920).

10/08/1920 capital authorised £5000 – issued £4900.

Old Company assets were bought by Brown for £3200 and handed over to the new Company.

1925 New dryer erected for £529 17 shillings including floor and plant.

A new drying stove was put into commission about 1925 – 1926.

Round kiln April 1926.

Sump and pump put in during coal strike of 1926.

November 1926 capital increased to £10,000.

R D Hendry died 20/01/1927

Jeffrey resigned 19/08/1930

E D Hendrie died October 1931

28/04/1932 Mr Morrison C.A. reported works facing difficulty and prices were raised.

Sept 1932 Brown reported clay for only 2 years.

23/02/1933 reduced prices by 5 shillings.

**********************************

Below – c. 1970′s – Waterlands Tileworks, Law, Carluke.

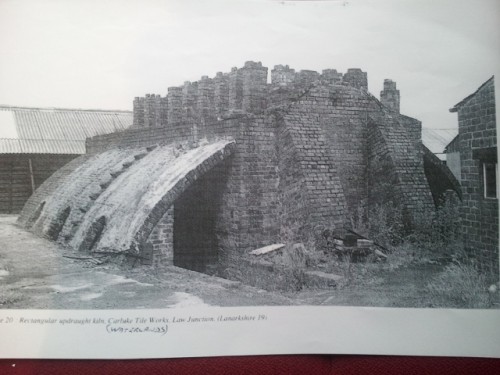

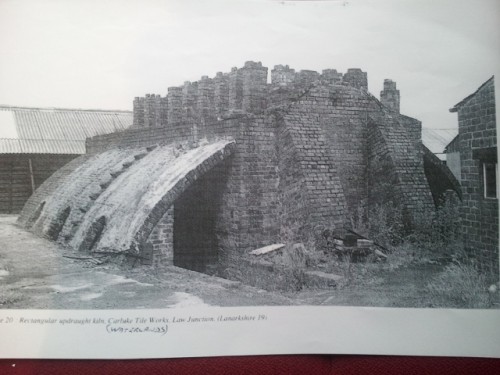

Below – Rectangular updraught kiln, Carluke Tileworks, Law Junction (Waterlands).

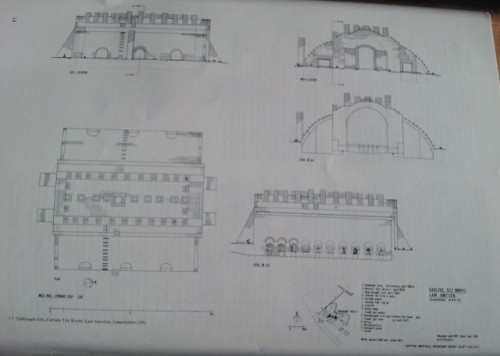

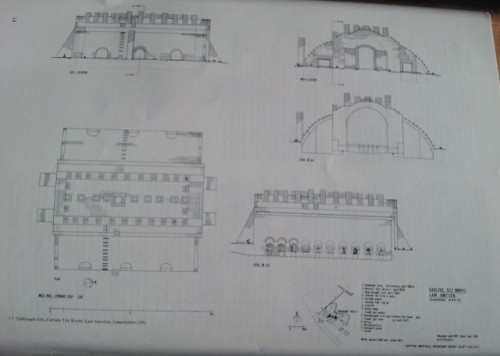

Below – Sketch of the updraught kiln, Carluke Tileworks, Law Junction, Carluke – RCAHMS. Measured and drawn by Graham Douglas in 1978.

Below – 2016 – These photographs were taken at the Carluke Tileworks.

Below – A chimney pot in the garden of the manager’s old house -the present owner states this was made at the works. It is not marked.

.

.

Below – A sandstone wheel measuring 20″ diam with the square central hole being 4″ x 4″. The current owner states it used to have a wood shaft and was turned by a thick rubber belt.

.

.

Below – A sandstone marked that originally stood on the road at the entrance to the works.

Below – The former offices of the Carluke Tileworks.

.

.

Below – This brick building was apparently a wash and shower house for use by the works employees. To the right of it is a retaining wall supported by buttresses.

.

.

Below – The interior of the wash house.

.

.

Below – This iron housing was situated just below the wash house and in a shallow pit. It would not open but may well house a water pump or similar.

.

.

Below – A pile of hollow blocks that likely formed the walls of the buildings on site. They appear to be of the same general type thought to be manufactured by the Scottish Clay Hollow Ware Company at Milton, Carluke

Below – 2 drainage tiles and a cored brick, all found on-site and highly likely to have been manufactured there. Both are probably misfires and ended up on the rubbish pile. Note the ‘bubonic plague’ look of the tiles. The tiles measure 13″ long by 2″ flat base and 3″ diam.

.

.

Below – Also found on site. It could be the top of a clay rhubarb forcer or similar although these normally had a little knob on the top to assist with removal.

12″ in diam with the internal ‘rim’ being 9″ diam. Each ‘rim’ is 1″ thick.

.

************************************

The Company traded under the name of Gold & Co. 1920 the Carluke Tileworks were known locally as the Waterlands Tileworks.

The works were opened in 1905 and closed in 1975. In spring 1978, the general condition of the works was rather poor. Parts of the main drying shed roof were off and much of the timber used for the sheds had been cut up for firewood. All machinery apart from some portable extruder’s and dies, several cutting off tables, electrically driven pug mill in the lower flower pot section and flower pot making machinery, are still in place.

The machinery for making flower pots in the 1930s and replaced in 1939 was 3 potters wheels. In 1939 the potter’s wheels were replaced by an inside stucco mould which was again replaced by a steel cap and die machine. The pot section had steam-heated drying cupboards. The pot section closed in 1965.

The winch for bringing the tubs up from the clay pit was removed in 1969. (This was a main (mane) and tail haulage system installed in the 1940s) The clay then came from the Milton Tile Works at Carluke, by road.

The Claypits – 2 worked out – the largest in 1947 – 48 and the smallest in 1968 – 69.

The extruder’s date from about the 1920s, electrically driven and could be moved about the drying sheds so that transporting the green tiles was cut to a minimum.

The pug mill in the flower pot section, originally line shaft driven from a stream engine but later fitted with an electric motor, originally had a wooden barrel. This, however, wore out and was replaced with a welded steel fabrication in the 1960s. The new barrel was made at a nearby engineering works but it also suffered from the same problem as the original. – the clay quickly wore out the bearing in the end cap and the rotary knives soon wore through the barrel.

The preparation of the clay was reasonably straightforward. It was mixed with a little water and originally shell or lump lime latterly hydrated lime, in a pug mill and then extruded into large blocks which were then taken to the portable extruders.

In all 20 were employed at the works. 7 in kiln work and the rest making tiles, The first job young lads had at the tile works was taking blocks of clay from the mill to the portable extruders. Their next move would be to placing the tiles on the shelves and finally onto kiln work.

The kilns –

Beehive – plan dimensions 1/D 7.2m, 9 fireboxes. The chimney was 2m square(outside) x approx 13.8m high. Chimney and kiln were made from brick. It used 10 tons of washed singles per burning cycle. Burning time was 72 – 84 hours approx and 17,000 mixed sizes (3″ to 6″) were fired.

Downdraught kiln – This was the largest kiln. It was built in 1945 and used 8 tons of washed singles per cycle, 72 to 84 hours and was loaded with approx 12,000 mixed sizes of tiles. The Chamber size was 3.6m wide and 9m long. 12 fireboxes. It was built with bricks and braced with steel section and used the same chimney as the beehive kiln.

Up draught kilns(2) – used about 12 – 14 tons of washed singles per cycle and again about 72 to 84 hours per cycle. 15,000 mixed sizes could be fired … All brick-built. The temperature of the kiln was usually judged by the colour of the tiles in it – also in updraught kilns, the required temperature had been reached when the hairs on the back of the hand were singed by waving it over the open flue!

Drying sheds – wooden louvred sides, asbestos sheet roof, wooden frames and brick columns and concrete and brick floors.

Tiles took between 1 and 3 weeks to dry depending on the weather and some parts of the shed were much better than others.

It is generally said that the tiles shrink 1/8″ for every 1″ of their length while drying out and up to 1/2″ max. (for the largest sizes while being fired.

Sizes made were 2 1/2″, 3″, 4″, 5″, 6″ and 9″.

Below – These flower pots are thumb pots and 1/2 pots. The thumb pots measure 2 1/4″ high x 2 1/2″ widest x 1 1/4″ bottom.

.

Thank you to the Carluke Parish Historical Society for their valuable information.

.

.

.

.

.

.

.

.

.

.

.

.