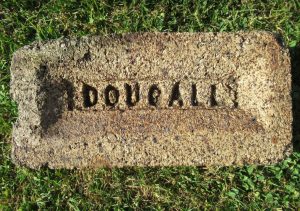

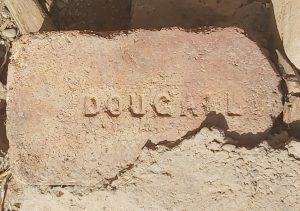

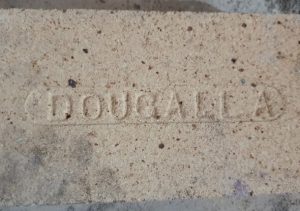

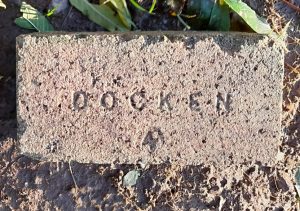

James Dougall & Sons Ltd, Bonnybridge, Scotland.

Telegraphic Address – “Gannister, Bonnybridge”

Telephone – Bonnybridge 70 and 71 (2 lines)

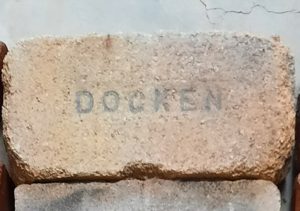

Water tube boilers – In water tube boilers, conditions are so varied that the choice of the correct refractory is of vital importance. For all conditions there is a DOUGALL quality firebrick. For a boiler working on a reasonable load with our forced draught and on a fuel without excessively corrosive ash, DOUGALL quality can be safely used throughout. For the high duty ?? raising units, where conditions are much more severe, DOCKEN quality is giving excellent service in the high temperature zones of arches and combustion chambers.

Marine boilers – In the mating type of boiler, particularly when oil fuel is used, a considerable part of the refractories are bolted to the metal casing, and for this purpose, a variety of special shapes are required. A tough firebrick of first-class shape, capable of withstanding thermal and mechanical shock is required. Under such conditions, DOUGALL quality is giving admirable service. This quality is used by both the British and foreign Admiralties. Both standard firebricks and the many intricate special shapes required are regularly supplied in DOUGALL quality for all types of marine work.

Pulverised fuel chambers – DOCKEN quality is recommended for the arches, whether these are sprung or suspended, and DIAMOND quality is recommended for the sidewalls, except where a very corrosive slag necessitates the use of DOCKEN quality for this position also, Occasionally coal-ash slags are of such nature that a semi-silica firebrick will give better resistance than even the high a luminous DOCKEN and DIAMOND qualities. In such cases J.D. Semi-silica Firebricks are recommended.

Oil fire furnaces – Although DOUGALL quality is giving consistently good results in marine type boilers, there are installations in which the oil-firing conditions are so severe that DOCKEN quality should be used. This may be particularly necessary in cases where the oil flame impinges directly upon the brickwork or where the furnace has to be rapidly cooled and reheated at frequent intervals.

Lancashire boilers – DOUGALL quality firebricks are generally supplied for this type of boiler. For the convenience of customers, stocks are carried of the following standard sizes in order that immediate deliveries may be affected:-

Boiler seating bricks . . . . . . 12″ x 12″ x 12″ and 12″ x 13″ x 12″

Circled Flue Covers . . . . . . . . . . . 24″ x 12″ x 3″

Plain Covers . . . . . . . . . . . . . Various sizes

Squares, Splits, Soaps, etc . . . . . . . . . Ground Fireclay

Fireclays and cements – These should be of qualities equal to or better than the refractories with which they are intended to be used. A Fireclay of the same brand is provided for each of the Company’s firebrick qualities. When a superior quality is required for surface washing or patching, a suitable DOUGALENE air-hardening cement should be used.

Dougalene air setting cement No 100 is recommended for the protection of exposed metalwork. It should be poured into position like concrete, when it sets immediately.

DOCKEN – 43%’Alumina . . . . For highest duty

J.D. – Semi-silica . . . . . . . . For highest duty

DIAMOND – 39-40% Alumina . . . For high resistance to thermal sapling and slag attack

DOUGALL – 37% Alumina . . . . The safe firebrick for all general purposes

DOUGALENE CEMENTS . . . . . In various qualities for repairing, jointing or protecting firebrick work, and for protecting exposed metalwork

Source – a brochure held at Falkirk museum and archives