J & M Craig Kilmarnock brick found in USA

— 17/09/2023Found by John Lowe in Long Island, New York State, USA. J & M Craig, Perceton Fireclay Works, Dreghorn, Ayrshire. . . . .

J & M Craig, Dean, Hillhead and Perceton Fire Clay Works, Kilmarnock and Longpark Pottery, Kilmarnock.

(Note – SBH – I have created separate pages for Perceton, Dean, Hillhead and Longpark. Where information does not relate to a particular works, such as Craig family history, I have added it to the Perceton page.)

Below – Source unknown – For a long time Kilmarnock was mainly celebrated for the production of bonnets, carpets and shawls, but of late years other trades have sprung up, such as engineering shops, wincey, tweed, and lace manufactories. It is also justly celebrated for the manufacture of fire bricks and other fire clay goods. This latter branch of industry, at the well-known works of Messrs. J. and M. Craig, is the subject of the present article.

The record of the enterprise of this firm might almost be said to be identical with the history of fire clay manufacture in Scotland. More than half-a-century ago — as far back as 1828 — the business was commenced at Dean Quarry, near Kilmarnock, by Mr Matthew Craig, father of the gentleman who is now the senior partner of the present firm. It was a small beginning. The entire plant consisted only of a pair of rollers for crushing the clay, one kiln for burning the bricks, and the necessary moulds, tools, &c. These gave employment to three men and two boys. At first, the motive power was communicated to the rollers from a rotary gin, but this soon had to be replaced by a steam engine with an increased plant. The operations of the firm so limited at the commencement, since then have been gradually but steadily extending and increasing, and they are now carried out on a very extensive scale indeed, in large works at Hillhead and Perceton, covering about six acres of ground and employing nearly four hundred men and boys.

When the Dean Brickwork was commenced there was then no other fire clay work in Ayrshire, and, excepting one or two near Glasgow, none in all Scotland. Now there are nearly a dozen works in Ayrshire, the same number in other parts of the West of Scotland, and about half-a-dozen works in the East country.

Fire clay manufacture at the Dean in those early days was limited to common building bricks—upon which, by the way, a duty of six shillings per thousand was then levied by the government—but by and by the clay was found to be very suitable for the production of other goods, such as compressed tiles for paving the floors of kitchens, entries, &c., troughs for cattle-feeding purposes, and salt-glazed pipes for sewers and for carrying water: to the making of which it was accordingly applied.

By this time several fire clay factories had been started in Ayrshire and various parts of Scotland, but the tact and energy of Messrs. James and Matthew Craig—who had succeeded their father—had gained the confidence of a large number of customers, and their business continuing to increase, they found it necessary, in 1861, to purchase the Hillhead Fire Clay Works, and again in 1862, to take over the Perceton Works. Largely increased means of supply were accompanied and followed by increased demand, and notwithstanding all the fluctuations of trade, the various goods made at these works have been in such constant request, that even with very large additions and improvements to the works of late, some difficulty is still felt in supplying all the orders.

Messrs. Craig have always been very prompt in discerning and opening up new branches in the manufacture of fire clay, improving the old methods of working, and in perfecting the quality of the goods turned out, and are now generally acknowledged to be at the top of the tree in the fire clay line—occupying in Scotland a position somewhat analogous to that of the Messrs. Doulton in England.

The process by which raw, worthless-looking clay, is transformed into valuable building material, or into more expensive and beautifully enamelled goods, is a very interesting one.

The fire clay is found underlying the coal in seams of from eighteen inches to three feet thick and is wrought along with the coal. At Hillhead, four pits supply the material and the fuel, which are conveyed in trucks by rail to the adjacent works. Here the clay is first submitted to the pressure of a grinding mill, and by the large iron wheels revolving on perforated plates, it is quickly reduced to a fine powder. From the grinding mill, it is raised by elevators to a “worm” which transfers it to the mixing pans, where, by the addition of water it is rendered plastic, and ready for the moulder’s benches. In the case of bricks, the clay is cast by hand in strong wooden moulds; and, if intended for common building purposes, the bricks are then dried in stoves, preparatory to being more thoroughly dried and burned in the kilns. If, however, it is intended that the bricks are to be glazed or enamelled, the process is a longer and more intricate one. After having the superfluous moisture removed in the stoves, they undergo an enormous pressure, under the pressing machine, and are then “dressed” by another machine, and after being carefully “finished” by hand, they receive a coat of the enamel in the liquid state and are then ready for the kiln. There the heat is at first applied very gradually but is steadily increased, until it reaches sufficient intensity to thoroughly incorporate the glaze with the body of the clay.

When taken out of the kiln the enamelled bricks are of a brilliant white colour, and we understand they are perfectly impervious to weather, non-absorbent of chemical or other vapours and incapable of being permanently soiled or dirtied. They are admirably adapted for lining back walls, and “wells,” in buildings where reflection of light is valuable, also for lining common stairs and closes, public baths, urinals, water-closets, passages and wards in fever and other hospitals; and generally for any purpose, where it is important to have beauty and lightness, combined with durability, non-absorption of vapours, and easiness to keep clean.

Coloured and printed enamelled bricks are produced in a variety of tints. The enamelled washing tubs, and enamelled sinks for kitchens, butler’s pantries, &c, are also moulded by hand and are very carefully finished and glazed, in the same manner as the enamelled bricks. These washing tubs and scullery sinks have a beautiful appearance; almost equal to porcelain, which, we believe, they greatly excel in strength and durability. Messrs. Craig informs us they are now extensively used in houses of the better class.

**********************************

J & M Craig Ltd – Kilmarnock – source Kenneth W Sanderson. An advertisement in Slater’s Directory of 1867 claims that the company was established in 1831, which would pre-date the Garnkirk Fireclay Company of Lanarkshire. This claim is probably based on the Dean Firebrick & Tile Company which was making firebricks on the lands of the Duke of Portland, east of Kilmarnock about this time. The Statistical Account of 1845 states that the parish of Kilmarnock was making considerable quantities of firebricks which were sold for £4 per thousand. Hunt’s Mineral statistics of 1858 records that the brickworks produced 4,365 tons a year of firebricks, chimney cans, pipes and retorts. The Dean area contained an excellent supply of freestone, and this quarry expanded to six acres to supply much of the stone used to build Kilmarnock, and in doing so swamped the fireclay works. The Kilmarnock Standard of 13th April 1872 has an interesting article on Dean Quarry and states that the first regular lessee was a Mr Law of Messrs Brown & Howie and that the quarry later passed into the hands of Martin Craig, senior, who with his two sons founded J & M. Craig.

The Perceton Fireclay Works at Dreghorn were taken over by J & M. Craig in 1863. Previously in 1858, they were owned by the freeholder and manufacturer, P. & M. MacReady who produced firebricks, pipes and retorts amounting to 6,552 tons a year: a substantial quantity for those days. They had agents in Glasgow, Dundee, Perth, Annan, Ayr and Ardrossan, which indicates the local nature of the business at that time.

The Hillhead Fireclay Works at Kilmarnock was taken over by Craigs in 1867 from John Gilmour & Company, who had owned it from at least 1858. Craig now became the largest firebrick company in Scotland, surpassing the Garnkirk Company; however, they were in their turn soon to be surpassed by the Glenboig Union Fireclay company which was formed in 1882.

The expansion of Craigs continued with the establishment of the Longpark Sanitary Pottery near Hillhead. The Muirhouse Brickworks near Irvine and the Lillieshill Fireclay Works near Dunfermline were brought into the group in 1896 when the company was incorporated as J. & M. Craig Ltd. The capital was £50,000, of which well over half was held by James Craig and his sons. A petition was brought before the Law Courts in June 1906 to dissolve the company as £45,000 of debentures were due for repayment. Whilst most of the holders were agreeable to extend the term, a minority refused. Assets were estimated at £127,427, and liabilities at £70,345, so the surplus exceeded the share capital: This led to a reconstruction of the company and J. & M. Craig (Kilmarnock) Ltd. was formed with a capital of £5,000 £1 ordinary shares and 15,647 £1 preference shares. The company continued to trade up to 1915 but was liquidated the following year.

Below – 1856 – Hillhead Brickworks.

1858 – Mineral Statistics of the United Kingdom of Great Britain and Ireland for 1858 – Hillhead, clay of coal measures. Name of freeholder – Duke of Portland. Manufacturer – John Gilmour & Co. Manufacture – Bricks, chimney cans, pipes and retorts &c. Estimated 5,928 tons annually.

Below – 12/06/1862 – Perthshire Advertiser – Alexander Campbell is an agent in the Perth area for J & M Craig, Dean, Hillhead and Perceton, Kilmarnock.

04/06/1864 – Kilmarnock Weekly Post – A large article concerning the community living around the Hillhead Brickworks as occupied by J & M Craig, complaining about the noxious smoke and gases emanating from the works. They also complain about the attitude and lack of acceptance of the problem by Messrs Craig.

Below – 02/06/1865 – Elgin Courier – Advert for J & M Craig, Dean, Hillhead & Perceton Fire Clay Works (The same advert is shown again in the Elgin Courier on 29/06/1866).

Below – 1867 – Advert J & M Craig, Dean, Hillhead & Perceton, Kilmarnock. (Apologies for the double print).

Below – 1868 – J & M Craig, Dean, Hillhead and Perceton Fire Clay Works, Kilmarnock.

1868 – John Boyle – Foreman, Hillhead Fire Clay Works, Kilmarnock. House Montgomery Street.

1868 – J & M Craig, Hillhead and Perceton Brickworks, Kilmarnock.

1869 – J. & M. Craig Manufacturers of fire & enamelled bricks, sewerage pipes,& all kinds of sanitary & plumbers’ earthenware; works, Hillhead & Perceton Fire Clay Works, & Longpark Pottery, Kilmarnock—Alexander Murray, 98 Commerce St. S S, agent.

30/04/1870 – Ardrossan and Saltcoats Herald – Ayrshire Agricultural Show – Stand no 22 – Messrs J & M Craig, Dean, Hillhead and Perceton fire clay factories, Kilmarnock. Judges awarded a medal for a collection of cattle troughs, horse mangers, milk coolers, sheep dipping trough and a collection of statuary, flower vases etc.

1872 – Hugh Finlay, Manager, Hillhead Brick Works, House 78 Hill Street, Kilmarnock.

1872 – John Boyle – Foreman, Hillhead Fire Clay Works, Kilmarnock. House Henrietta Street.

1872 – J & M Craig, Coalmasters and Fire Clay Manufacturers, Dean, Hillhead and Perceton Fire Clay Works and Hillhead Colliery. Office Hillhead.

1872 – William Kerr, Clerk, Hillhead Fire Clay Works.

14/08/1880 – The Ardrossan and Saltcoats Herald – The Industries of Kilmarnock – Messrs J & M Craig’s Fire Clay Works – Since the time when the Israelite’s were compelled to make bricks without straw by their hard taskmasters, the making of bricks has continued to be a very primitive looking business. Within recent years some attempts have been made to supersede the common-mode by machinery, but they have failed both in point of quality and economy and bricks continue in most places to be made by hand. In other respects, however, fire-clay manufactures have greatly improved, and innumerable useful and artistic objects are produced from common clay. The beautiful figured vases, for instance, which adorn our public park, and are invariably to be found in every flower garden, are a slight indication of the useful and beautiful articles that are made ; and we are credibly informed that in the matter of kitchen sinks, troughs, &c., the enamelled fireclay manufactures are rapidly pushing the cast iron articles out of the market. That is only one example of the direction in which this industry is moving. There are over 100 fire-clay manufactories in Scotland, and that of Messrs Craig including their works at Hillhead and Perceton is perhaps one of the largest. The Hillhead work alone covers between four and five acres of ground. It will be within the knowledge of our readers that at the beginning of the century, the father of Messrs Craig was quarry master at the Dean to the Duke of Portland. It was here, it may be said, that the present firm took its rise. In the year 1828, Mr Craig first began to make bricks, and from that date up to the time when Messrs Craig bought the Hillhead and Perceton Works, the business of brick-making was carried on at the Dean Quarry. About 19 years ago, when they acquired those Works, there was nothing manufactured but common bricks and tiles, but under the new impulse received from them, the more artistic branches of the trade began to be cultivated. At Hillhead all the enamelled brick work is manufactured; but the vases and other artistic works are made at Perceton, the clay their being of a more suitable nature for such articles. The principal articles manufactured at Hillhead, besides the common bricks and tiles, are chimney cans, garden edging, sewer traps, pickling pots, cattle troughs, and white enamelled bricks, sinks, edgings for gardens, &c., the largest of all being gas work retorts. They also occasionally manufacture full-length human and animal figures. The firm does an increasing business in the white enamelled sinks; while the enamelled edging is coming into general use everywhere its effect amid flowers and shrubs being alike refreshing and artistic, as is shown in the new cemetery. The clay used in the Hillhead is wrought out of pits in the same manner as coal. The various pits around the works have a clay, as well as a coal seam, the former being found under the latter; and there is a line of rails connecting the pits and the brick-work, besides a junction with the mainline of the Glasgow and South-western Railway. When the clay comes from the pit it is a hard, dry substance, having not the slightest cohesion. It is finely ground into fine dust in a powerful mill, consisting of two large iron rollers travelling around a circular trough. This mill is enclosed in a large building, and is connected with an ingenious set of machinery by which the clay dust, when sufficiently ground, passes through a sieve, and the refuse, or the part that requires to be re-ground, is thrown back into the mill, into which water is run, until the clay is wrought up to the requisite softness and cohesion, after which it is ready for use. Bricks are very simply made, one man being able to make 3000 or 4000 a day on piece-work. The moulder stands at a table, on one end of which is heaped up a load of clay. Before him, he has the mould, in shape like a hollow box with the ends knocked out. The mould is wet, and the man takes a piece of clay and presses it with his hands, and then removes the superfluous clay by drawing a smooth piece of wood over the mould. A boy immediately lifts the mould away, having already placed another mould on the table ready for use. In this manner, the work goes on very rapidly, one man generally requiring the two boys to lift the bricks and place them on the floor. The pipes, again, are made by the clay being pressed down through an iron die by a steam revolving shaft. The pipes are cut off, by a self-acting knife in lengths of three feet, and are manufactured at the rate of 150 an hour. The flanges are formed separately in stucco moulds and attached to each of the pipes. The rooms in which these are manufactured are all laid below with steam pipes, and the bricks lie there for a short time until they are ready to be placed in the kiln. The floor bricks and those that have to be examined, pass through a pressing machine, equal to a weight of six tons, before passing into the kiln. There are altogether twelve kilns in the Hillhead Brickworks, and the bricks or other articles are so placed in these that the heat passes between each. Each kiln will hold perhaps about 10,000 bricks, and they remain in for twelve days. The other description of work we saw going on were equally simple, although requiring some little practice to perform. The four sides of the troughs, for instance, are moulded separately, and then placed together within perhaps a couple of inches of each other at the corners. The moulder then takes a piece of clay and fills them in at the corners, solders them together as it were; and in the course of half-an-hour the moulds can be taken off, and they are enamelled inside, and afterwards sent to the kiln. All this class of work is cast in stucco moulds. As we have said, the most of the fancy work is manufactured in Perceton, and as what is called terra cotta is coming greatly into fashion for architectural facings, &., there is little doubt that in this line the trade has a progressive future.

Below – 13/08/1883 – Aberdeen Press and Journal – Buchan’s Patent infringements by Hurlford Fireclay Works and Caledonia Fireclay Works.

14/06/1884 – Kilmarnock Standard – One of the reasons why Kilmarnock has not felt the depression of trade so severely as some other places, is the variety of the trades carried on in the town. Our working people do not depend entirely on one branch of manufacture, so that though there should be a collapse, greater or less, in one branch, others may have full employment. The practical extinction of the once extensive calico-printing industry was more than made up for by the development of the iron trades, and the growth of the wincey and tweed manufactures has gone far to fill the blank caused by the decline of carpet weaving. It is gratifying to notice the introduction of a new branch of industry in any direction, but more so when it points to the increased business capacity of a firm that has already acquired considerable fame in another direction, to some extent akin to the new undertaking. Within the last few weeks the Messrs. J. and M. Craig, Hillhead Works, have inaugurated the pottery trade, or manufacture of white earthenware goods of various kinds and qualities. The other branches of their Fire Clay Works have been enormously extended of late, and now by their enterprise and foresight, they have introduced a new branch of clay manufacture, and one which we hope will prove the nucleus of a business equally extensive with that hitherto so ably carried on. This week we had the pleasure of a visit to the new works, and by the kindness of Mr Taylor, the energetic manager, and Mr McLauchlan, the foreman of this branch, were initiated into some of the mysteries of the pottery manufacture.

The new works are situated to the east of the Fire Clay Works and are in the form of a parallelogram, 130ft. by 120ft., the workshops and warehouses lying on the east and west sides, with a central roadway between. The raw material, which consists of ball clay, Cornwall stone, China clay, and flint, is brought from the South of England by sea and rail, and we understand Messrs. Craig have such facilities for carriage that they will be able to compete favourably with Staffordshire (the great seat of the pottery trade), as well as with Glasgow and Ireland. They have also been able to secure the services of a competent foreman, and workmen from Staffordshire; Belleek, Ireland; and Glasgow so that there is every guarantee of the quality of their goods.

The clay and other materials are first carried to the “slip house,” and there ground into a very fine powdery paste by means of a revolving granite stone. It is then conveyed into separate tanks, run into a large vat, and mixed in a liquid state in the proportions necessary for the quality of the goods. These are called “Blunging pans.” The mixed clays are then passed through a fine sieve, by means of machinery, and taken up by force pumps into the “clay press,” which is strongly bound and screwed to sustain a pressure of 901bs. to the square inch, and which contains thirty leaves or cells. The mixture is here passed through strong cotton cloth made specially for the purpose. The water is thus runoff and the clay collected in bags containing about l cwt. each, or about one-and-a-half tons in all. This can be charged and emptied three times daily. In this state, it is like ribbed webs two feet wide and an inch thick. These are put in the ” pug mill,” where the clay is cut by knives placed like a steamer’s screw, and the purpose is to drive out the air, make it uniform in consistency, and quite solid. This operation is done twice, and the clay is then ready for manufacture.

We now turn to the modelling shop, where the moulds of stucco are fashioned. This is, of course, a critical operation, for on the quality of the mould will depend to a large extent the beauty of the article as to shape. From the modelling shop, we go to the making shop, where all the different articles are fashioned. We saw the whole process in the manufacture of an ewer of antique shape. The bottom of the ewer is first made; then the body in two parts, a gauge giving it uniform thickness; when the two parts have been brought together the inside is smoothed with a fine sponge, wet, and then run over with a piece of India-rubber sheet, the jug revolving on a pivot. The bottom is then put on and a strong strap drawn down on the outside of the whole. In this condition, it is placed on a shelf for about a couple of hours until it is ready for the drying stove. The handle is made separately and attached. The heating stove is in the centre of the premises and entered from both sides of the working section of the room. It is heated by exhaust steam passing through a series of pipes, to the extent of about 100 degrees, according to the quality of the goods, and the same test is applicable to the time the articles remain in it. Here, as elsewhere, they require to be tenderly handled, as they are easily soiled or damaged. This shop is 60 feet by 37. On leaving the drying shop the articles are taken to the other side of the parallelogram and put first into the “biscuit kiln.” Each article is placed in a “seggar,” which is made of fire-clay, and the seggars are piled in tiers or bings 25 in height and numbering in all 1,250. When the oven is filled the aperture is closed by means of fire-clay, and the fires lighted. Here they remain in “white” heat about fifty hours. Small openings are left to show when the material is sufficiently burned. When properly “biscuited,” the goods are warehoused, examined piece by piece, and all defective ones laid aside. They are then taken to the dipping house, in which each is immersed in the glazing vat, after which they are carried to the “glost” or glazing kiln, where they are put in “seggars” arranged in tiers as in the biscuit kiln, and allowed to burn for about eighteen hours. It takes from thirty to forty hours to cool this kiln and clear the goods. They are then taken to the “glost” warehouse, where they are examined, as in the biscuit warehouse, and all defective pieces laid aside. The goods are now ready to be warehoused as stock, or packed in crates, placed in wagons in the lye that has been carried to the side of the new works, and sent thence to their destination. It will thus be seen that the raw material enters one end of the parallelogram and comes out at the other end a finished product.

All that we have described applies to the purely white earthenware. When the goods have to be gilded, marbled, or enfigured, they are taken upstairs to a separate branch of the establishment. To be marbled the pattern is first put on a piece of tissue paper from a copperplate impression, and then transferred to the article by rubbing. The pattern adheres to the dish, and the superfluous stuff is washed off. The decorations by painting are done by the hand, and so is the gilding, the articles being placed on a revolving stand. We much admired the steadiness and dexterity with which this artistic work was done by the lady employed in its execution. Only practice could produce such fine work. All the decorated goods are taken to a small kiln, where heat is applied for six to eight hours, according to the class of goods. They are then put in sets, ready for the market.

The whole of the machinery in the works is moved by a very handsome horizontal engine of fully 20-horse power, made by Messrs. Grant, Ritchie, and Co. The engine has a patent governor, exceedingly sensitive, and we believe the only one of the kind in town. Close to the engine is the house where the glaze is made, but as the process is generally deemed a secret we did not inquire into it. It is not our intention to give a list of all the articles made in the works. Suffice it that the chief are, cabinet stands for house and ship use in white, marble, or gold; water-closet basins; plugs; toilet ware of a great variety of shapes and patterns in white, printed, enamelled, and gilt. There are also jugs of diverse patterns, many of them of antique design; cheese covers, jelly shapes, and others—all of them, in so far as our unpractised eye could judge, of fine finish and quality. Among the specialities are two articles which may be particularly mentioned, as Messrs. Craig are the only parties who have the right to make them—a right acquired from the patentee. One of them is called “Armstrong’s patent self-flushing urinal.” The water rises to a certain height in the small basin, and when that is reached an automatic flush takes place and carries off the contents. The basin fills again and the same process is repeated with the utmost regularity. The urinal being also trapped, no bad smells come from the drain. The other article is termed “Shields’ patent flush-out closet and trap combined.” It would need a diagram to describe the construction of this article. Suffice it that, as in the other, there is always from one to two inches of water in the pan, so that it is kept always clean. In both of these, the useful and the handsome have been well combined, and a considerable demand is expected for them.

We could not leave the works without wishing the Messrs. Craig every manner of success in their new undertaking. It is but the germ of what we trust will ultimately develop into an extensive and profitable branch of industry, giving employment to hundreds, enlarging the trade of the town, and yielding that profitable return which is expected and desired. If business tact, upright dealing, energy, and determination, coupled with a due regard to the rights and comforts of those in their employ, should command success, then the new branch of local industry set on foot by Messrs. J. and M. Craig will ere long be a flourishing one.

1886 – J. & M Craig, manufacturers of fire bricks, paving tiles, vitrified pipes, cattle troughs, chimney cans, flower vases, and other fire clay goods, also all kinds of sanitary & plumbers earthenware, Hillhead & Perceton Fire Clay Works, Longpark Pottery & Hillhead Colliery. (Page 235).

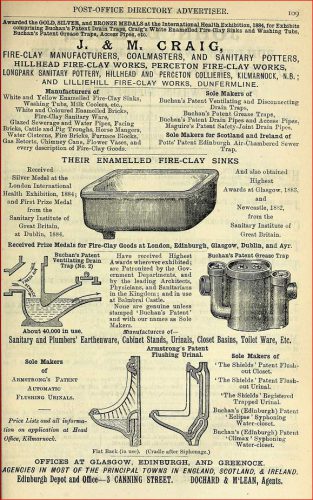

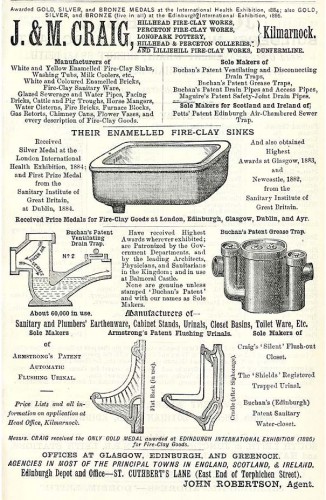

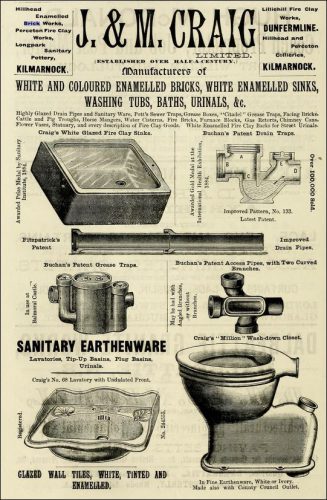

Below – 1886 – 1887 – J & M Craig, Kilmarnock advert.

Awarded the Gold, Silver and Bronze medals at the International Health Exhibition 1884 for exhibits comprising Buchan’s patent drain traps, Craig’s white enamelled fire clay sinks and washing tubs, Buchan’s Patent grease traps, access pipes etc

J & M. Craig, Fire clay manufacturers, coal masters and sanitary potters – Hillhead Fire Clay Works, Perceton Fire Clay Works, Longpark Sanitary Pottery and Perceton Collieries, Kilmarnock, N.B and Lilliehill Fire Clay Works, Dunfermline.

Sole Makers of

Buchan’s Patent Ventilating and Disconnecting Drain Traps,

Buchan’s Patent Grease Traps,

Buchan’s Patent Drain Pipes and Access Pipes,

Maguire’s Patent Safety-Joint Drain Pipes.

Sole Makers for Scotland and Ireland of Potts’ Patent Edinburgh Air- Chambered Sewer Trap.

Manufacturers of

White and Yellow Enamelled Pire-Clay Sinks,

Washing Tubs, Milk Coolers, etc.

White and Coloured Enamelled Bricks,

Fire-Clay Sanitary Ware,

Glazed Sewerage and Water Pipes, Facing

Bricks, Cattle and Pig Troughs, Horse Mangers,

Water Cisterns, Fire Bricks, Furnace Blocks,

Gas Retorts, Chimney Cans, Flower Vases, and every description of Fire-Clay Goods.

Their enamelled fire clay sinks received Silver Medal at the London International Health Exhibition, 1884 and First Prize Medal from the

Sanitary Institute of Great Britain at Dublin, 1884.

And also obtained Highest Awards at Glasgow, 1883 and Newcastle,1882,

from the Sanitary Institute of Great Britain.

Received Prize Medals for Fire-Clay Goods at London, Edinburgh, Glasgow, Dublin, and Ayr.

Buchan’s Patent have received highest awards wherever exhibited and are Patronized by the Government Departments, and by the leading Architects,

Physicians, and Sanitarians in the Kingdom; and in use at Balmoral Castle.

None are genuine unless stamped ‘Buchan’s Patent’ and with our names as Sole Makers.

Buchan’s Patent Grease Trap and Buchan’s Ventilating Drain Trap (No. 2)-

About 40,000 in use.

Manufacturers of – Sanitary and Plumbers’ Earthenware, Cabinet Stands, Urinals, Closet Basins, Toilet Ware, Etc.

Sole makers of Armstrong’s Patent Automatic Flushing Urinals.

Price Lists and all information on application at Head Office, Kilmarnock.

Sole Makers of

‘ The Shields ‘ Patent Flushout Closet.

‘ The Shields ‘ Patent Flushout Urinal.

‘The Shields ‘ Registered Trapped Urinal.

Buchan’s (Edinburgh) Patent ‘ Eclipse ‘ Syphoning Water-closet.

Buchan’s (Edinburgh) Patent ‘Climax’ Syphoning Water-closet.

Offices at Glasgow, Edinburgh and Greenock. Agencies in most of the principal towns in England, Scotland and Ireland. Edinburgh Depot and Office— 3 Canning Street. Dochard and McLean. Agents.

1888 – Alexander Murray (Agent for Messrs. J. & M. Craig), Perceton and Hillhead Fire Clay Works, Kilmarnock. Office, 98, Commerce Street.—

For upwards of twenty years the well-known Hillhead and Perceton Fire Clay Works, Kilmarnock, of which Messrs. J. & M. Craig are the proprietors, have had a depot and warehouse in this city, Mr Alexander Murray of the above address being the representative of the firm. Mr Murray, does a very extensive business, in fire clay goods, lime, and cement. The well-known sanitary ware manufactured by Messrs. J. & M. Craig has long occupied a prominent and well-sustained position in the trade. All the latest improvements have been introduced into its construction, and the well-known and durable character of their fire clay has made this ware very popular with sanitary engineers, architects, and builders.

The stock held by Mr Murray embraces glazed sewerage pipes, patent traps and cesspools, grease boxes, white and yellow enamelled sinks, washtubs, and milk coolers, white and coloured enamelled bricks ; also Buchan’s patent, sanitary appliances, including the famous drain ventilating traps, of which about 70,000 are now in use all over the country, and in America, the Colonies, &c. ; patent trap fittings, patent improved drain-pipes, patent grease traps, as used at Balmoral Castle, the Highland residence of the Queen; and Buchan’s anti-bell traps, Maguire’s patent safety-joint drain pipes, and Potts’s patent Edinburgh air-chambered sewer trap. Buchan’s patent drain traps awarded a gold medal at the International Health Exhibition, London, 1884, and highest awards at the other recent Sanitary Exhibitions. Potts’s patent trap was also awarded a gold medal at the International Health Exhibition, London, 1884, and at the Edinburgh International Exhibition, 1886. Messrs. J. & M. Craig received the only gold medal awarded for fire clay goods.

Mr. Murray is also agent for Messrs. Craig’s, Longpark Sanitary Pottery, Kilmarnock, at which they manufacture sanitary and plumbers’ earthenware, including cabinet stands, plug and tip-up basins, urinals, water closets, toilet ware, &c., the “Silent” flush-out closet, the Shield’s flush-out closet, and Armstrong’s patent automatic flushing urinals.

Below – 1889 – 1890 – J & M Craig, Kilmarnock advert.

Below- 26/09/1889 – Glasgow Evening Post – J. & M. Craig, of Kilmarnock charged with employing 2 females form 6 in the morning to 9 at night.

Below – 1895 – Hillhead Fireclay Works.

Below – 1896 – J & M Craig advert.

Below – 1896 – 1897 – J & M Craig Advert.

1903 – J & M Craig Limited – Hillhead & Perceton Fire Clay Works & Longpark Pottery, Kilmarnock

Below – 1905 – 1906 – J and M Craig, Hillhead, Perceton and Longpark, Kilmarnock

10/01/1907 – Greenock Telegraph – The funeral took place yesterday of ex-baillie James Craig of Messrs J & M Craig, Hillhead Fireclay Works, Kilmarnock whose death occurred on Sunday. The town bells were tolled during the obsequies and the funeral was very largely attended, the Provost, Magistrates and Town Council being among the mourners.

16/07/1907 – British Clayworker Vol 16 – Fire-clay Works on Sale.—On the 28th ult., at Kilmarnock, the works, etc., of J. & M. Craig, Ltd. (in liquidation) were exposed for sale by public auction. The property of the company was detailed as follows:—The fire-clay and pottery works carried on at Hillhead, Kilmarnock, together with the farm and lands of Hillhead, with the farm steading thereon, and the field known as Longpark, extending in all to 80 acres or thereby, together with the works, buildings, fixed machinery plant, railways, pit rails above and below ground, office buildings, office furniture, stock-in-trade, etc.; also, the lease of the colliery and minerals, at Hillhead and Knockinlaw, and the colliery plant, moveable machinery, moulds, copper plates, etc., and the warehouse and office fittings and furniture at the company’s depot in Edinburgh, with the lease of the premises, and stock-in-trade of every kind there. The whole was exposed at the upset price of £35,000, but there were no offers, and the sale was adjourned.

Below – 1908 – Hillhead Fireclay Works.

31/03/1917 – Hamilton Advertiser – Important sale of fireclay work, plant, machinery, buildings etc. at Hillhead Fireclay Works, Kilmarnock on an early day …

Below- 13/10/1917 – Hamilton Advertiser – Hillhead Fire Clay Works for sale.

.

Below – 20/10/1917 – Hamilton Advertiser – Shirlaw, Allan & Co, Auctioneers, Hamilton – On an early day – at Hillhead Fire Clay Works, Kilmarnock. Important sale of Fire Clay Works plant and machinery.

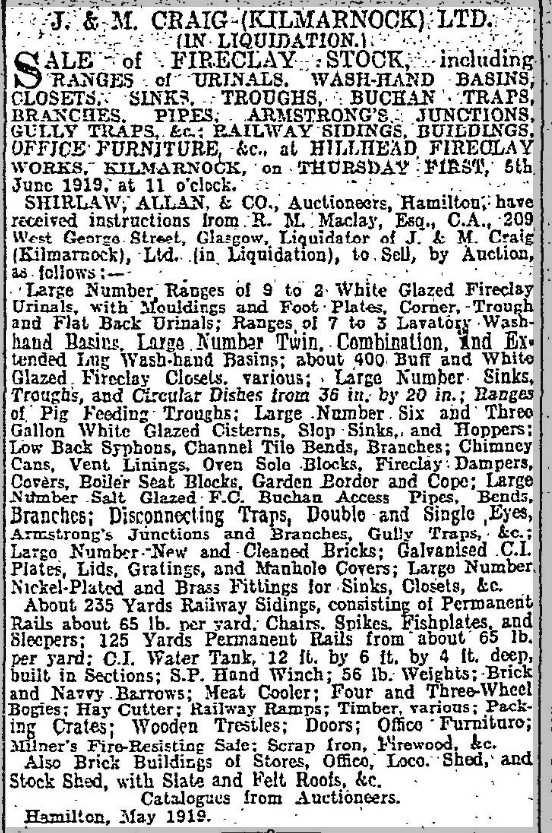

Below – 02/06/1919 – The Scotsman –

J & M Craig, Kilmarnock in liquidation. Sale of stock.

Below – 04/06/1919 – The Scotsman – J & M Craig, Kilmarnock in liquidation. Sale of stock.

1938 – The works are not depicted on this map.