Brick sizes, variations and standardisation

The following is a great piece of work and research – source.

Part of the interest of brickwork is the ability to observe subtle (and some not so subtle) differences in size as you walk around different towns. When you ‘get your eye in’ you will find that different-sized bricks, and especially bricks where the sides are in a different ratio, stand out and catch your eye, even before you resort to a ruler.

Several things influenced the size of bricks. They mustn’t be too big, or they will be too heavy and awkward to pick up with one hand while applying mortar with a trowel held in the other. They mustn’t be too small, or a wall will need more of them, and more mortar and more time to lay it.

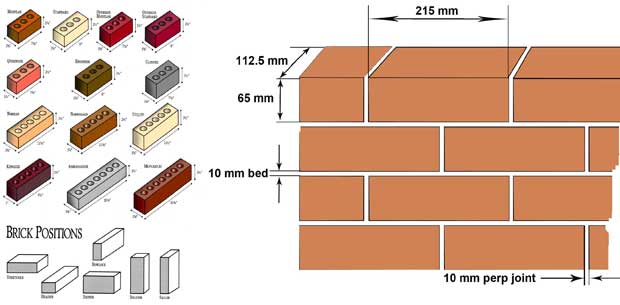

In modern times most bricks in the UK are made to a standard size of 65 x 102.5 x 215mm and laid with nominal 10mm mortar joints, but in former times the size varied quite a lot.

Some early medieval bricks were as big as 13″ x 6″x 2″. Late 15th century bricks were mostly about 9½” x 4½” x 2″. A charter in 1571 specified 9″ x 4½” x 2¼”, and in the 18th century, Parliament specified 8½” x 4″ x 2½”, which is equivalent to the modern metric brick of 215mm x 102.5mm x 65mm.

What upset the apple cart was a brick tax imposed by the government in 1784. The tax was paid per brick, so brick makers responded by making much larger bricks, which meant fewer were needed for a given size wall. An extreme case was Joseph Wilkes of Measham, who produced bricks double the normal size (110 x 110 x 235mm) known locally as ‘Jumbies’ or Wilkes’s Gobbs”, see right. The government later set an upper limit of 150 cubic inches (10″ x 5″ x 3″) for a ‘brick, which was still much larger than bricks had been before the tax.

The tax was repealed in 1850, but by this time, many brick makers, especially in the Midlands and North, had moved from hand-made to machine-made bricks. Having invested heavily in machinery it wasn’t easy for them to revert to the smaller sizes, which meant that big bricks persisted for a long time afterwards. As a result, you are likely to find bigger bricks as you move farther north, in buildings built before the introduction of standard modern bricks.

*******************

Brick sizes have changed significantly across different time periods in the UK, with imperial brick sizes used until recently (imperial brick size is 228 x 110 x 68+ mm). The metric system was adopted in 1965 (metric brick size is 215 x 102.5 x 65mm) and is now the standard. While metric bricks can be incorporated into an existing imperial masonry structure by increasing the mortar joint bed, it is always best to source the original brick size to ensure consistency and a better visual finish.

*******************

The Scottish Employers’ Council for the Clay Industries – One useful initiative was the standardisation of brick sizes, at the surprisingly high number of 108. The common size is 9 x 4 ½ x 3 inches. However, each length of 9’ requires a breadth of 4 ½”, 6’ and 9’. Lengths based on 12’, 13 ½”, 15’, and 18’ require similar breadths. All these lengths and breadths require side arch and end arch tapers varying by 1/8’. Finally, the thickness can vary from 3’, 2 ½’, 2’, 1 ½’, and ½’. If you add up all these sizes and leave out a few because they are not too much in demand you will come to over a hundred sizes. It was still a big improvement on the previous practice. The names of such a series of sizes vary in different parts of the country, but in Scotland, they include squares, scones, pups, whelps, soaps, bullnoses, feathers, and cupolas amongst others.

******************

Below – 1625 – King Charles sets a size for bricks in London and a price.

18/12/1856 – North British Daily Mail – An article on the issues surrounding irregular brick sizes.

30/12/1941 – The Scotsman – Builders and bricks – Liberton, Edinburgh, December 29, 1941. Sir, – Referring to the recent letter by “Brickmaker, I feel I must make some further reference to the increased cost in building that will result from the introduction of the 2 7/8 inch brick to Scotland. From the builder’s point of view and experience of brick building, the lower the brick the more expensive it is to build, as extra labour, bricks, and mortar are required to produce the same area procured by the higher brick. If the 2 7/8 inch brick were adopted as “standard, ” the bricklayer would have to lay at least 10 per cent, more bricks per day, and in so doing, he would use approximately 6 per cent, more mortar to produce the equivalent yardage of 3 1/4 inch bricks, as it is yardage that counts at the end of the day and not the number of bricks laid. “Brickmaker” also ignores the fact that the Government have “two” standard sizes of bricks in England, 2 5/8 inch South of Birmingham, and 2 7/8 inch bricks in the North, thus defeating any plan for universal standardisation. Assuming that the brickworks can produce the additional 48 million 2 7/8 inch bricks necessary, to equal the existing annual square yardage built with 3 1/4 inch bricks, this extra quantity may become an additional cost, as it remains to be seen whether the brickworks will produce the smaller brick at a reduced rate, or charge the same, as for 3 1/4 inch bricks. The reference to women’s labour is rather surprising, as, to the knowledge of the building trade, women and youth labour have always been employed in the production of bricks. Brick builders are quite agreed on standardisation, but only where it is economical and they are quite convinced that bricks of 2 7/8 inch will greatly increase the cost as well as retard the progress of wartime work. I am &c J. B. Alexander, Jun, President, Edinburgh and District Master Builders Association.

06/04/2000 – Architects Journal – Masonry materials – Of all the masonry materials, stone masonry tells us the least about its construction age. The bond of the stones can broadly distinguish between medieval (rubble-cored), post-medieval (brick-backed), and twentieth-century (steel-framed), although any age of construction could be solidly bonded.

Unlike stone, brickwork gives many clues to its age. After use by the Romans, clay bricks were re-introduced into the UK in the 1400s, initially in the south and east, near to locations where suitable clay could be dug out and burnt in wooden clamps. With the decline of medieval timber-framed buildings and the advent of canals, railways, and better roads, bricks were transported and used throughout the country.

By the eighteenth century, brick was the most common material for houses, and many old timber-framed houses were gentrified by re-facing with bricks or mathematical tiles, particularly the latter after the first brick tax of 1784.

Since the 1400s the width of a brick has always been about 4.5 inches (114mm) – governed by the need to grasp and lay it with one hand. But the length and thickness of a brick, has not always been as constant as today, being influenced by government legislation, regional variations in firing thicknesses of clay, bonding, joint thickness, and local practice.

Medieval bricks were longer and thinner than modern bricks – as at Herstmonceux Castle, East Sussex. circa 1440 which has 2 inch (51mm) thick bricks. But beware modern imitations, particularly amongst Edwardian buildings. Parliament fixed brick sizes in 1776 at 8.5 x 4 x 2.5 inches (216 x 102 x 63mm). Fighting wars is expensive. In 1784, after the American War of Independence, parliament taxed each brick used, so some bricks were made larger, up to 10 x 5 x 3ins (254 x 127 x 76mm)2. In 1803, these large bricks were further taxed, and this was avoided by reducing the size to 9 x 4.5 x 3ins (229 x 114 x 76mm). In 1850 the brick taxes were repealed, and brick sizes gradually standardised, rising four courses per foot (304mm), except in the north of England where they rose four courses per 13 inches (330mm) for much of the nineteenth century.

In 1851, machinery was designed for making pressed bricks in volume, eventually replacing handmade bricks, except for best quality work. Machine-made bricks, such as Flettons which were first made in the 1870s, are generally smoother and more regular in appearance than handmade bricks.

At the end of the First World War, the Local Government Board highlighted the need to supplement traditional construction with non-traditional types. Amongst other materials and components, concrete bricks and sand-lime bricks were introduced, which like machine-made clay bricks, are smooth and regular, but with a more uniform texture.

Bricks were traditionally laid in a lime mortar until Portland cement became more popular in the late nineteenth century, thanks to its cheapness, faster set, and safer handling properties. Lime mortar is usually more friable than cement mortar, although laboratory analysis is the only sure way of distinguishing between them.

To improve the strength of Georgian and Victorian lime-mortar brickwork bonding, timbers were usually set in their inner faces or occasionally in the core of the walls – such as in Tittenhurst Park, Berkshire around 1800. Better quality Victorian buildings had hoop iron laid in the bed joints instead – as at Marlborough House Mews, London from around 1862 and the now-demolished Stonebridge Park Power Station, London of 1906.

In early brick buildings, the bond is often irregular, but English Bond became the norm by the end of the sixteenth century. Flemish Bond was introduced in the seventeenth century and had largely replaced English Bond by the early eighteenth.

In the latter half of the Georgian era, snapped-header brickwork was frequently used in cheap, speculative construction. Although apparently solidly bonded, many cheap Georgian external walls only had first-quality bricks in the external face. Headers in the outer face were mostly snapped- off where they met the inner face due to misalignments in the coursing of the two faces.

This may have been the unwitting precursor of cavity (two-leaf) brickwork, or perhaps that was the nineteenth-century cheap walling, Rat Trap Bond, where bricks were laid on edge to reduce consumption leaving cavities within – as at Coleshill Model Farm, near Swindon around 1854.

The earliest known true cavity wall is around 1804, recorded by bre ip16/88, although most early examples are found in late Victorian buildings, not signalled by the customary Stretcher Bond, but usually by Flemish Bond with false headers.

Some early cavity walls have no ties between the leaves. Where used, ties varied from cast or wrought iron bars to extra-long hollow glazed header bricks. By the 1920s, Stretcher Bond brickwork and mild steel cavity ties had become the norm. For better durability, ties gradually evolved after World War II through galvanised mild steel to stainless steel, and even to copper, bronze, and plastic in a few cases.

After 1945 the brick inner leaf of cavity walls was replaced by dense concrete blocks, and then in the mid-1970s, the ‘energy crisis’ arising from the 1973 Middle East War accelerated the change to insulative lightweight concrete blocks.

Some cavity walls have bed-joint reinforcement, such as Expamet, Bricktor, or stainless steel wire, the modern equivalents of Victorian hoop-iron, and lime mortar is making a comeback thanks to its greater tolerance of structural movement than cement mortar, and modern safer ways of handling the lime.

Masonry pointing is readily renewable, and therefore it is an unreliable indicator of age, although Georgian tuck-pointing and post-war recessed pointing are seldom aped.

2018 – Nowadays most bricks in the UK are made to a standard brick size of 215mm long, 102.5mm wide and 65mm high (215×102.5x65mm) and laid with a nominal 10mm mortar joint. However, there is a growing trend towards more non-standard brick dimensions. Longer, thinner formats are very much in vogue at the moment with brick heights below 50mm and brick lengths of more than 500mm not uncommon. These brick sizes are being used by architects and designers to create some very impressive, modern styles of buildings.

2018 – Imperial handmade bricks, Grindle, Shropshire –

• Before 1965 and the introduction of the standard metric sized brick, all bricks produced in the UK were created using imperial measurements. That’s why using imperial bricks for the restoration

or extension of properties built before this time is vital.

• The regional variation of bricks was originally created due to a lack of transport links – local clays were used for brick production which dictated the colours used. Those regional colours are now often a conservation requirement.

• After the Great Fire of London in 1666, an Act of Parliament was introduced to stipulate more durable building materials for house construction, which led to an increase in brick production.

• The first bricks produced were a lot smaller and slimmer in size. When the brick tax was introduced in 1784, manufacturers increased their brick sizes to compensate.

• Handmade bricks stand the test of time, with many 15th and 16th century buildings still around today. The open-pore structure of handmade bricks is naturally durable, allowing water to enter and escape without damaging the face or structural integrity of the bricks. The use of lime mortars is also a major factor contributing to the longevity of brickwork, allowing buildings to flex and move and its natural self-healing properties enabling any movement cracks within the mortar to repair themselves.

2016 –

Various countries have various standard brick size and dimensions, however, brick can be made in multiple shapes and sizes, depending on its application. If bricks are large, it is difficult to burn them properly and they become too heavy to be placed with a single hand. On the other hand, if bricks are small, more quantity of mortar is required. Hence, a standard dimension is determined for various brickworks. The actual size (or the specified size), is the real dimension of the brick. The nominal size is the actual size plus the width of the mortar joint. Most bricks are manufactured in such a way that the nominal sizes fit into a grid of 4 inches, which complies with the modules of other building materials such as doors, windows, and wood components.

Standard Brick Size in England – “In England, the length and width of the common brick has remained fairly constant over the centuries but the depth has varied from about two inches (about 51 mm) or smaller in earlier times to about two and a half inches (about 64 mm) more recently. In the United Kingdom, the usual size of a modern brick is 215 × 102.5 × 65 mm (about 8 5⁄8 × 4 1⁄8 × 2 5⁄8 inches), which, with a nominal 10 mm (3⁄8 inch) mortar joint, forms a unit size of 225 × 112.5 × 75 mm (9 × 4 1⁄2 × 3 inches), for a ratio of 6:3:2.” – Wikipedia

Standard Brick Size in the United States – “In the United States, modern standard bricks are (controlled by American Society for Testing and Materials i.e. ASTM) about 8 × 3 5⁄8 × 2 1⁄4 inches (203 × 92 × 57 mm). The more commonly used is the modular brick 7 5⁄8 × 3 5⁄8 × 2 1⁄4 inches (194 × 92 × 57 mm). This modular brick of 7 5⁄8 with a 3⁄8 mortar joint eases the calculation of the number of bricks in a given run.” – Wikipedia

Standard Brick Size in Australia – According to Boral Company in Australia, the standard brick size (or the working size) is 76mm high, 230mm long and 110mm wide as per the Australian Standard AS4455. Some bricks are made with different work sizes. 50 mm and 90 mm high bricks, 90 mm wide bricks and 290 mm long bricks are used for different structural and aesthetic effects. Larger bricks are often used for more economical laying and as a design feature either on their own or combined with smaller bricks.

In cyclonic areas larger (140 mm wide x 90 mm high x 290 mm long) hollow bricks are used to allow reinforcement and grouting in the wall. Wider (150 mm wide) bricks can also be used in walls requiring lower sound transmission, higher fire resistance levels and higher load-bearing capacity depending on the specific brick properties.

Standard & Nominal Brick size in India – In India, the standard brick size is 190 mm x 90 mm x 90 mm as per the recommendation of BIS. With mortar thickness, the dimension of the brick becomes 200 mm x 100 mm x 100 mm which is also known as the nominal size of the modular brick.

Standard Brick Size in Nepal – According to National Building Code (NBC 205: 1994) of Nepal, the bricks shall be of a standard rectangular shape, burnt red, hand-formed or machine-made, and of crushing strength not less than 3.5 N/mm². The higher the density and the strength, the better they will be. The standard brick size of 240 x 115 x 57 mm with 10 mm thick horizontal and vertical mortar joints is preferable. Tolerances of -10 mm in length, -5 mm in the width and ±3 mm in thickness shall be acceptable for the purpose of thick walls in this Mandatory Rules of Thumb (MRT).

Note: The main objective of these Mandatory Rules of Thumb (MRT) in the National Building Code of Nepal is to provide ready-to-use dimensions and details for various structural and non-structural elements for up to three-storey reinforced concrete (RC), framed, ordinary residential buildings commonly being built by owner-builders in Nepal.

Face brick dimensions: Face bricks are the bricks used on exterior surfaces of a structure or houses. In the table below, we have given the standard dimensions of face brick on various countries listed in alphabetical order (both in imperial and metric units).

| Standard | Imperial (in) | Metric (mm) |

| Australia | 9 × 4⅓ × 3 | 230 × 110 × 76 |

| Denmark | 9 × 4¼ × 2¼ | 228 × 108 × 54 |

| Germany | 9 × 4¼ × 2¾ | 240 × 115 × 71 |

| India | 9 × 4¼ × 2¾ | 228 × 107 × 69 |

| Romania | 9 × 4¼ × 2½ | 240 × 115 × 63 |

| Russia | 10 × 4¾ × 2½ | 250 × 120 × 65 |

| South Africa | 8¾ × 4 × 3 | 222 × 106 × 73 |

| Sweden | 10 × 4¾ × 2½ | 250 × 120 × 62 |

| United Kingdom | 8½ × 4 × 2½ | 215 × 102.5 × 65 |

| United States | 7⅝ × 3⅝ × 2¼ | 194 × 92 × 57 |

A must-read is an article on brick sizes by Martin Hammond in his booklet entitled Bricks and Brickmaking.

‘Happy DIY Home‘ – A comprehensive online article on brick sizes.