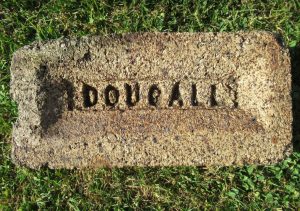

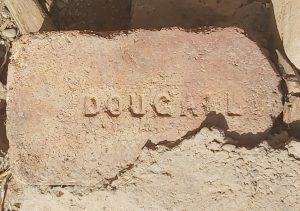

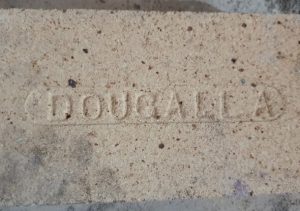

1899 – 1900 – James McDougall & Sons Ltd – Bonnyside Brickworks, Bonnybridge. Sole agents Wright & Stewart 59 St Vincent Street, Glasgow. ( Should McDougall actually read Dougall?)

21/01/1899 – Falkirk Herald – … All the brickworks to the east and the west of our district have been kept very busy, and the prospect at present, with the numerous new works buildings going up, are quite as good they were a year ago. Messrs James Dougal(l) and Son (Limited), fire-clay brick manufacturers, Bonnybridge have put in new boilers and mills, and extra stove accommodation, during the past year, and have been very busy …

1903 – Dougall James & Sons Limited, Bonnyside Fire Clay Works, Bonnyside R.S.O. Stirlingshire; T A ” Ganister.”

Below – 1903 – Advert – Dougall James & Sons Limited, Bonnyside Fire Clay Works, Bonnyside.

19/05/1906 – Falkirk Herald – A miner, named William Rae, living in Skinfiats, was fined 10s, or seven days’ imprisonment, for having committed a breach of the peace on 3rd May. Thomas Douglas, brickmaker, Bonnyside Terrace. Bonnybridge admitted having created a breach of the peace on 1st May at Bonnyside Brickworks. High Bonnybridge. The Sheriff passed a sentence of 10s, or seven days imprisonment.

1907 – Same advert as for 1903.

02/02/1907 – Falkirk Herald – Gas Association’s visit to the Bonnyside Fireclay Works – The members of the Western Section of the Scottish, Junior Gas Association paid a visit on Saturday afternoon to the Bonnyside Fireclay Works of Messrs James Dougall and Sons, Limited. The party, which numbered about seventy, included representatives from the leading Scottish gas companies and gas departments of corporations. Amongst those present were —Mr McLeod, of Provan Gas Works, president of the association; Mr Lowe, assistant manager, Glasgow Gas Department; Mr Hislop, Uddingston; and Mr Simpson, Bellshill. The Rev. J. C. Russell, D.D.; Messrs Robert Dougall, E. M. Stewart, and E. G. Smith, directors of Messrs Dougall and Sons, Limited, and Mr G. Wink Wight, C.A., secretary, received the party and welcomed them on behalf of the company. The works were gone over, the machinery being seen in motion, and the various processes of making fireclay goods shown in full operation. Of especial interest were the various blocks and retorts used in gas works as well as in iron, steel, and chemical works. The party then descended the pit and examined the underground workings. Thereafter dinner was served in the company’s hall, and Dr Russell welcomed the members of the association. Mr E. M. Stewart, manager and director, read a paper on the history and manufacture of fireclay goods.

17/08/1907 – Falkirk Herald – To let, for such a number of years as may be agreed upon, with entry from Martinmas, 1907, the farms of Bonnyside and Blairlee, presently occupied by Mr John Cuthill and others, extending to about 500 acres. Full particulars from Jas Dougall & Sons Limited, Bonnyside Firebrick Works, Bonnybridge.

07/09/1907 – Falkirk Herald – The employees of James Dougall and Sons, Ltd., Bonnyside Brickworks, held their annual excursion last Saturday, the venue being Crieff. Fully 200 took advantage of the special opportunity for visiting the charming Perthshire tourist and health resort. The party left special-train 8 a.m. and reached Crieff in due course. The weather was in its best behaviour, which enabled the visitors to view the charming scenery under the best conditions. Mr E. M. Stewart, managing director, accompanied the excursionists, and he presided at the dinner, to which the firm generously entertained the employees, in the Town Hail. There, a splendid repast was enjoyed, followed by songs from several of the company, Mr Tom Wishart presiding at the piano with much acceptance. In addition, Mr Stewart managing director entertained the office staff to luncheon and a drive to the famed Drummond Castle Gardens. In addition to proofs of the goodwill of the firm already alluded to, it falls to be noted that the firm also defrayed half the railway fare of the entire workers, a kindness much appreciated all. Pipe Major Macfarlane accompanied the trippers, and his excellent pipe music contributed his quota to the success and pleasure of the trip. After a delightful visit, the party entrained for home about 7 p-m., and Greenhill was reached about 9 p.m., everyone in the happiest mood at tho sight-seeing and pleasure of the day.

28/09/1907 – Falkirk Herald – Bonnybridge intimidation case. 2 strikers fixed. At Falkirk Sheriff Court on Monday, before Sheriff Moffatt, William Paton, clay miner, Waverley Place, High Bonnybridge, and James Porter, miner’s drawer, Bonnyhill Cottage, Bonnybridge, were charged with having, along with another man, on 13th September, on the Drove Road, leading between Bonnybridge and Bonnyhill and near Bonnyside Brickworks, occupied by James Dougall and Sons Limited, brick manufacturers, with a view to compelling Alex. Fleming, labourer, residing at 126 Gordon Street, Camelon, who was then employed as a labourer in their clay pit, to abstain from working, intimidated him, and threatened to “go for him,” and challenged him to fight, cursed and swore at him, and used abusive and threatening language towards him. The complaint further stated that the accused, along with other persons, followed Fleming in a disorderly manner, shouting and cursing, for 150 yards along the road, and that Paton seized hold of Fleming, and pushed him against a stone wall … Edward M Stewart, manager of James Dougall and Sons Limited, who was the first witness deponed that the firms miners had been on strike since 7th Sept … Archibald McNeil, manager of the clay pit at the works, stated that on the date in question he accompanied Fleming along the road to his home … David Gillespie, foreman in the Bonnyside Brickworks … Both found guilty and Paton fined £3 3s or 30 days imprisonment and Porter fined 30s or 15 days imprisonment.

02/10/1907 – Falkirk Herald – At Falkirk Sheriff Court on Monday, Michael McAndrew, miner’s drawer, Griffiths’ Buildings, High Bonnybridge, was charged with having, along with two other men, who were before the Court last week, on 13th September, on the Drove Road, leading between Bonnybridge and Bonnyhill, and near Bonnyside Brickworks, occupied by James Dougal and Sons, Limited, brick manufacturers, with a view to compelling Alex. Fleming, labourer, residing at 126 Gordon Street, Camelon, who was then employed as a labourer in their clay pit, to abstain from working, intimidated him, and threatened to “go for him” and challenged him to fight, cursed and swore at him, and used abusive and threatening language towards him. The complaint further stated that the accused, along with other persons, followed Fleming in a disorderly manner, shouting and cursing, for 150 yards along the road. A plea of guilty was tendered by the accused. Mr Will Stevenson, solicitor, Falkirk, in the course of a statement on behalf of the accused, stated that the reason he was not present at the last calling of the case was owing to the fact that he went to Prestongrange, and four days later the complaint was served at his house in Bonnybridge. The first thing he knew of the case having been brought up was when read of it in the evening papers. He at once sent a message to his mother to send the police, and he went home, and he called three times at the police office in Bonnybridge, but the constable was out on all three occasions. When walking through Bonnybridge on Sunday night he was arrested and refused bail. Sheriff Moffatt, in imposing a fine of 30s, or ten days’ imprisonment, said he would cause an inquiry to be made into the hardship which it was alleged the accused had suffered.

23/11/1907 – Falkirk Herald – New joint-stock company. Amongst the new joint-stock companies registered in Scotland this week appears the following:- James Dougall and Sons, Ltd., Works, Bonnybridge, capital £50,000, divided into 20,000 preference and 30,000 ordinary shares of £1 each – to enter into an agreement with George Wink Wight, C.A., Glasgow, the liquidator of the existing business of fire brick, etc., manufacturers, for the purchase of the property, effects, and undertaking of James Dougall and Sons, Ltd., and to carry it on. Signatories;- James C. Russell, D.D., 9 Coates Gardens, Edinburgh; Sir James B. Smith, Clifford Park, Stirling; Robert Dougall, brickmaker, Woodlea House, Bonnybridge; E. M. Stewart, brick manufacturer, 29 Randolph Road, Stirling; Edwin G. Smith, shipping agent, Clifford Park, Stirling; J. Paterson, writer, 45 West Nile Street, Glasgow; and James Andrew, writer, 160 West George Street, Glasgow. The first directors are – Rev. Dr Russell, Sir J. B. Smith, and Messrs Dougall, Smith, Stewart, and Paterson.

25/01/1908 – The Scotsman – Court of Session. Rights in a Stirlingshire burn. William Forbes V Rev. Dr Russell and James Dougall & Sons Ltd, Bonnyside Brickworks, Bonnybridge. The Rev . Dr Russell has been proprietor since 1878 of the property, of Bonnyside, adjoining that of the pursuer, and the other defenders, Dr Russell’s tenants carry on business as brick manufacturers at Bonnybridge. The case had to do with the disputed rights in the running water of the burn which in 1781 formed the march between Callender and Bonnyside, which in the course of years had been diverted. The principal conclusions of the summons were for declarator that the operations executed by the defenders in June 1906 within the lands of Bonnyside upon the channels of the stream were illegal and unwarrantable and prejudiced the pursuer’s rights and that the defenders were bound to restore matters to the condition in which they stood prior to these operations. An interdict was also craved to protect the pursuer’s rights affecting the flow of the water in the northwest channel of the stream. Lord Dundas, in the Outer House, assoilzied the defenders from the conclusions of the summons as laid, with expenses. The Court recalled the judgment of the Lord Ordinary, and assoilzied the defenders from the conclusions of the summons, with expenses. The Lord President held that it was clear that there had been a diversion of the stream from its original channel sometime between 1797 and 1842. There was no evidence to show what particular arrangement had been made at that time, and it was, therefore, for the Court to determine upon inferences from the facts as to the probable agreement which had been made between the parties. The losing party, through his author, had himself to blame for this result, and as no record had been kept which would have shown anything to the contrary, the stream had been diverted out of the Callendar lands and taken wholly into Bonnyside lands. If there had been any arrangement that Callendar was thereafter to share in the water the natural thing to have done would have been to make a bank at the place where the stream left the Callendar estate to the effect of still allowing a portion of the stream to flow down the old channel. This, however, had not been done; and the pursuer’s claim that a cut had been made off the new channel so as to take a portion of the stream back to the old channel at the point founded upon was, upon the face of it, unlikely, because that would have involved the stream being turned off at right angles down the solum of a drove road which then, at least, was being used for traffic. The evidence of the Ordnance Survey may of 1859, and of people with works upon the banks of the old channel, founded upon by the pursuer, did not go for much, because there were at least some other sources from which a certain supply of water still flowed into the channel. On the whole matter, the facts and the inferences to be drawn from them were in favour of the theory that the defenders, at the time that the new channel was made; obtained the right to the whole of the water. His Lordship was satisfied that the Lord Ordinary, who had evidently given great attention to the case, would if he had thought himself free to come to a conclusion of fact, have come to the same conclusion as his Lordship. Lord Kinnear concurred, and the Lord President stated that Lord Ardwall, who heard the case, also concurred. Lord Mackenzie did not hear the case …

25/08/1909 – Falkirk Herald – Success of a local mining engineer – It is gratifying to note that Mr Archibald McNeil, M.E., late pit manager of the firm James Dougall and Sons, Ltd., Bonnyside Brickworks, at the recent Board of Education examination in mining, held South Kensington, has been awarded a first-class certificate in honours, and the King’s medal in coal and metal mining. Mr McNeil was a student in the Coatbridge mining engineering classes, and his success reflects credit on that institution and demonstrates his thorough equipment for the conduct of mining engineering classes, to which he is devoting himself.

21/09/1910 – Leven Advertiser – At a meeting of the shareholders of James Dougall & Sons Limited, fire clay manufacturers, Bonnybridge, Mr W. Walker, Comely Bank, Leven was appointed a director.

19/11/1910 – Falkirk Herald – Presentation to mine manager. In the Bonnyside Hall on Wednesday evening the miners of Bonnyside Brickworks (Messrs J. Dougall and Son) met and presented John McPhail with a barometer and Mrs McPhail with a gold-mounted umbrella on the occasion of their departure. Mr E. M. Stewart presided, and the gifts were presented By Mr James Blair. Mr McPhail was also the recipient of a bible and travelling rug and Mrs McPhail a wrist bag from the members of Bonnyside Works Mission. The presentation was made by Mr C. Cruise, and McPhail suitably acknowledged.

Below – 1911 – Advert – James Dougall & Sons.

25/03/1911 – Falkirk Herald – Sequel to the Bonnybridge fracas. John Logan, labourer, Bonnybridge. was charged with having (1) on 18th curt. at the works office. Bonnyside Brickworks occupied by Jas. Dougall and Sons, Ltd., assaulted David Gillespie, works foreman. High Bonnybridge by kicking him on the thigh with his booted foot, and (2) assaulted John McCafferty, labourer, by striking him on the face with his fists and biting him on the neck. The accused pleaded guilty to the first charge only. The Fiscal accepted the plea. Mr Will. Stevenson, solicitor, Falkirk, appeared for the accused and explained that Logan was employed at the brick works at 22s per week. On the date mentioned he only received £1, and seeing the foreman passing, he kicked him with the side of his boot. Accused was then knocked down and severely handled, both of his eyes being blackened. Traces of the injuries received could still be seen, and in view of the fact that the accused had been severely handled, Mr Stevenson asked his Lordship to admonish him. Fine 20s, or ten days’ imprisonment, was imposed.

16/09/1911 – Falkirk Herald – James Dougall and Ltd., appealed against the valuation of £225 placed on their brickworks at Bonnybridge, and against a valuation £15 sought for a small hall there. J. T. Brown, Stirling, who represented the appellants, said that the neighbouring brickworks were simply entered in the valuation roll in respect to minerals, and James Dougall and Sons naturally thought that they had a decided grievance in the respect that they were assessed for their brickworks, while other brickmaking firms ware not. He understood that the assessor’s position was that this was rendered necessary by the terms of the Valuation Acts. He (Mr Brown) was not prepared to dispute that Mr Barr was wrong in that. Looking strictly at the form of the Acts, it was necessary to put in an entry regard to buildings. But he thought the assessor ought to have found, if he could, some way under the Valuation Acts of equalising the valuations, so as to put the different brickworks on the same footing. He understood that the assessor, in estimating the value of the minerals for separate assessment, had put the same rate of lordship as in the case of the other brick making companies, who were tenants of their works. The rate was on the finished article, and the appellant’s contention was that they could not have the finished article without works. If the assessor put in a separate valuation for the works he should diminish the assessment put on the minerals, so as to arrive at an amount that would be similar to that paid by other companies. He (Mr Brown) suggested that James Dougall and Sons, Ltd., would be perfectly satisfied with £420 as a total valuation (to include minerals and works) in whatever way that valuation was entered. As it was, either the buildings were entered in the valuation roll too high or the minerals were entered too high, or both were entered too high. Mr David Mitchell -It might be well to consult Lloyd George about this case. (Laughter). The Court dismissed the appeal, on the understanding that negotiations would be entered into for a reasonable settlement next year. With regard to the valuation placed on the hall adjoining the firm’s works. Mr Brown said it was a small building, which was placed at the disposal of the inhabitants by the firm rent free. He suggested that £5 would be a fair valuation. The Assessor – The Bonnybridge Silica and Fireclay Company had a similar hall at their works, and it is entered in the valuation roll at £12. The Court fixed the valuation of the firm’s hall at £10.

13/12/1911 – Falkirk Herald – John Hawthorn, labourer, Bonnyside Terrace. High Bonnybridge, appeared upon a charge of having on 30th ult., at Bonnyside Brickworks, assaulted Minnie Gemmell, brick worker, kicking her on the haunch with his booted foot. He pleaded guilty and stated that the girl had used bad language to him. The Fiscal said the girl was only 16. She received a severe kick. A fine of 10s or five days imprisonment was imposed.

29/07/1911 – Falkirk Herald – John Porteous, Labourer was sentenced to 40 days imprisonment after stealing a silver pocket watch from a jacket hanging in the workmen’s shed at Bonnyside Brick Works, High Bonnybridge.

29/07/1911 – Falkirk Herald – Notwithstanding the heavy rains the past week, the fire which broke out a fortnight ago in a field on Bonnyside estate still in a smouldering condition. The field affected is the property of Messrs James Dougall and Sons. Ltd., Bonnyside Fire Brickworks, and not the Bonnybridge Silica and Fireclay Company, as erroneously stated last week’s issue.

09/03/1912 – Falkirk Herald – The firm of Messrs J. G Stein Co Ltd, Bonnybridge and Castlecary Fireclay Works and the Messrs Dougall and Co, Bonnyside Fireclay Works closed their works on Saturday last due to the restrictions and scarcity of coal. Up to 700 hands are affected by the stoppage.

11/03/1912 – The Scotsman – Denny. A number have been added to the list of unemployed during the past few days, bringing the total up to about 880, the principal contributants being Messrs J. G. Stein & Co, Bonnybridge and Castlecary Brickworks, 600 men and Messrs Dougall & Co Ltd, Bonnybridge Fire Brick Works, 200 …

03/04/1912 – Falkirk Herald – We regret to record the death of Mr Robert Dougal(l), of the firm of James Dougal and Sons, brickmakers, High Bonnybridge, which took place at his residence, Woodlea, on Sunday. The deceased gentleman, who was about 60 years of age, belonged to the Doune district. He came to Bonnybridge about 40 years ago to assist in the brick and tile manufacturing business carried on by his uncle, the late Mr George Turnbull. Thereafter he began business for himself and subsequently was associated with the brickmaking business which his brother, the late Mr George Dougal, began at High Bonnybridge a good many years ago. The deceased was for some time in Ceylon, engaged in business there with his brother, Mr Wm. Dougal. The late Mr Dougal was a Liberal in politics, and at election times lent his hearty support to that political party. He was a member of Denny West U.F. Church. Of a quiet and retiring disposition, he was greatly liked in the village and district, and many will regret his demise. He gave liberally and unostentatiously of his means to many, deserving cause. The funeral took place to Denny Cemetery on Wednesday.

11/05/1912 – Brickworkers strike – Bonnybridge is once more in the throes of a labour fight. On this occasion, it is at Bonnyside Brickworks (Messrs James Dougall and Sons, Ltd.), where over 150 men have ceased work as a protest against the dismissal of four of their number. The men came out on Tuesday night, and strong picketing has taken place. The district is quiet, and no disturbances have so far occurred. On Thursday night a public demonstration was held at The Toll when addresses were delivered to a large gathering by Councillor Alexander Turner, Councillor Anderson, and Mr J. McKenzie. Tho men are members of the National Union of Gas Workers and General Labourers, and Mr J. McKenzie, organising secretary, has taken their interests in hand.

19/06/1912 – Falkirk Herald – Bonnybridge strike riot. Exciting scenes. Police baton charges.In connection with the strike of the workers at Messrs James Dougall and Sons’ Brickworks, High Bonnybridge, a riot which attained serious dimensions occurred at the works on Friday night last. The strike, which has been in progress for about six weeks, arose out of several skilled workmen being asked to undertake some labouring work. About 70 men, including between 40 and 50 labourers, who have been brought from Glasgow are at present employed in the works, the Glasgow men being housed in a hall adjacent to the works, where they have been protected by a small force of the Stirling County Police.

The disturbance commenced by a crowd of between 50 and strikers rushing the works from the rear. To get into the premises they had to climb a wooden paling, and this they clambered over. Three policemen were on duty, and these, with the assistance of several of the Glasgow labourers, who were working overtime, proceeded to drive the mob back. The crowd took advantage of the ammunition in the form of piles of stones and bricks which were lying about the works, and with these, they pelted the police and workers. The police drew their batons and charged the mob, while the labourers did what they could with their fists, and after a short encounter, the attackers were driven back over the paling. They left behind them two of their number who had been injured in the tussle, and these were arrested and placed under the charge of one of the constables. The rioters proceeded to the railway, which overlooked the works, and then came round to the front gate. By this time their numbers had increased to about 400. They marched up a narrow road leading to the works gate until they t reached the mission hall where the Glasgow men were lodged. This they bombarded with sticks, bricks, and stones, and all the windows to the front of the building were smashed. Several of the 30 or 40 men inside were slightly injured by the missiles. The rioters proceeded to the entrances of the works, where they were met by two constables and the managing director, Mr E. M. Stewart, who barred further progress. Sticks were carried by a considerable number of those in the crowd, while one man was noticed to be armed with a hatchet. A determined effort was made to get inside the works, but the three defenders, though greatly hampered by the flying stones, prevented the rioters from gaining an entrance. The two policemen made another baton charge and gradually drove the mob back from the gates out into the main road. Meanwhile, the Falkirk police had been summoned by telephone, and a force of a dozen constables, under Superintendent Greenhill, arrived on the scene when the crowd had been driven on to the road. The Falkirk contingent on their arrival drew their batons and joining the local constables charged the crowd, which then rapidly dispersed. None of the constables on duty were injured despite the fact that during the whole course of the disturbance they were in the centre of a shower of bricks and stones. The two rioters who had been injured and arrested were conveyed to Falkirk. The district was quiet during the weekend, a fact, due to a considerable extent, to the Glasgow workers having gone home on Saturday. They resumed work Monday morning. The two men who were arrested were William Moffatt and Bartholomew O’Rorke, clay miners, Bonnybridge. They were brought before Sheriff Moffatt in the Falkirk Sheriff Court on Saturday for purpose of omitting declarations on charges of mobbing, rioting, assault, and breach of the peace. They had been somewhat badly mauled in the course of the fracas and appeared before the Sheriff with their heads bandaged. On the advice of their agent, Mr John Liddell, solicitor, Falkirk, they declined to make any statement. Mr Liddell, on behalf of the accused, made an application for bail, but the Procurator-Fiscal opposed it and the application was refused by the Sheriff in hoc statu. On Monday a further application was made, and on this occasion the Sheriff admitted the accused to bail, fixing the sum for each at £25 and the two men were liberated on Monday afternoon, the bail money being provided it is understood by their union.

Further charges – The two men named William Moffatt and Bartholomew O’Rorke, along with several others who were arrested on Monday in connection with the riots appeared before Hon Sheriff Substitute Watson on Tuesday afternoon and emitted a declaration. The complaint bore that William Moffat, Bartholomew O’Rorke, Paul McPhail, Michael O’Connor, Thomas Paton, Daniel Holmes, Henry Young, Terence Cole, Hamilton Osborne and John Macdonald, brickworkers, Bonnybridge were charged with having at Bonnyside Brickworks occupied by James Dougall and Sons Ltd, brick manufacturers, formed part of a riotous mob, which acting of common purpose, behaved in a riotous and disorderly manner, threatened violence to the lieges, invaded the said brickworks from the East and assaulted Patrick Stewart, William Love and others who were working in said works and threw stones and bricks at them and also assaulted Alexander Turpie, Alexander Richardson and James McAllister, constables of the Stirlingshire Police, while on duty, and threw stones and bricks at them. Thereafter invaded or attempted to invade the said works from the west and assaulted Edward Martin Stewart, managing director of James Dougall and Sons Ltd, and Charles Savage, James Smith, James Brannan and Francis Scanlan, brickworkers by throwing stones and bricks at them; again assaulted the said Alexander Turpie and Alexander Richardson by throwing stones and bricks at them and striking them with sticks; and breaking 23 panes of glass in the windows of a Mission Hall and one pane of glass in the window of a grocers shop adjoining said brickworks and committed a breach of the peace. The accused were all represented by Mr John Liddell, solicitor, Falkirk and acting on his advice, they declined to make any statement in regard to the charges and were committed to prison pending further procedure. Mr Liddell applied for bail on behalf of the men including Moffat and O’Rorke, whose bail was fixed at £25 each on Monday, and bail was fixed at £20 each.

22/06/1912 – Falkirk Herald – In the Falkirk Sheriff Court yesterday, before Sheriff-Principal Lees, thirteen petitions were presented for the ejectment of tenants from houses at Bonnybridge, of which Messrs James Dougall and Sons, Ltd., brick manufacturers, are the proprietors. Mr Brown, of Messrs Archibald and Brown, solicitors, Stirling, who appeared for the petitioners, said that the notices for removal were given so far back as 1st May. The defenders, who were represented by John Liddell, solicitor, Falkirk, stated that simultaneously with the notices for termination of the let, the tenants had received letters intimating that on the expiry of the notices the rent would be 10s per week, payable in advance. The agent contended that this annulled the notices and set a new contract between the parties. Sheriff Lees upheld this view of the case and said he thought new notices would require to be given. The letters accompanying the notices were anomalous. The petitions were dismissed but in view of the fact that the Sheriff did not think the pursuers were acting vindictively, limited the costs against them to £l.

02/07/1912 – The Scotsman – The Bonnybridge brickworkers strike. A breakaway among the employees at Messrs James Dougall & Sons’ Brickworks, Bonnybridge, who are at present on strike, occurred yesterday when about 100 men returned to work. Numbers of the men had to be turned away on account of the fact that the clay pits were not full, the miners being also out of work, but it is expected that by today it will be found possible to take in a larger number of the strikers. Yesterday, including men from Glasgow and elsewhere who have been employed at the works during the strike, there were about 200 men engaged. The brickworkers left their employment over eight weeks ago as a result, they alleged, of several skilled workers being asked to undertake labouring work. The employers point out that the incident occurred during the coal strike when there was very little work being done and they state that the men were asked to assist in emptying a kiln so that work might be provided for the brickworkers on the succeeding day. Considerable distress has been experienced during the latter weeks of the strike by the workers and in a number of cases, families are on the verge of complete destitution.

13/07/1912 – Falkirk Herald – A comprehensive account of the trial. The accused were found guilty.

09/10/1912 – Falkirk Herald – Unusual point in a summons for rent. In Falkirk Sheriff Court yesterday, before Sheriff-Substitute Dallas, proof was heard in an action for rent at the instance of James Dougall and Sons, Ltd., brick manufacturers. Bonnybridge, against William Sullivan, brickmaker, Broomhill, Bonnybridge. The pursuers sought decree for £4 10s, being nine weeks rent of a house from 7th May to 9th July 1912, at 10s weekly. The defender admitted occupation of the house during the above period but stated that the rent was only 3s 9d weekly and that he was agreeable to pay this rate. He further denied that there was any contract, lease, or arrangement whereby he agreed to pay 10s per week. It appeared from the evidence that a strike took place at the pursuer’s works about the beginning of May last, and as a result, the defender was affected and left the pursuers’ employment on Tuesday, 7th May. The pursuers had written to him stating that, failing his leaving their house the same day as he left the employment (in terms of his contract of let), the rent thereafter would be 10s per week, payable forehanded. Accordingly, when the defender lifted his wages on 7th May the pursuers retained 10s for a week’s rent in terms of their letter. The defender demurred to this and instructed his agent to recover the money, and this was done, the pursuers returning the 10s. A few weeks later the pursuers applied for payment of rent at the rate of 10s per week, but the defender again declined to pay more than 3s 9d per week. The present action is accordingly raised. The pursuers’ agent contended that by remaining on in the house the defender had acquiesced in the new arrangement, while the defender’s agent argued that there had been no new contract come to between the parties and that the rent chargeable must be as before, namely, 3s 9d per week, the evidence that pursuers had returned the first 10s retained from the wages, and the fact that defender had later repudiated the demand for rent at 10s per week, clearly indicating that defender had never agreed to the pursuers’ new terms. The Sheriff made an avizandum.

Below – 1913 – Bonnyside Brickworks.

Below –

1913 – Bonnyside Brickworks.

09/08/1913 – Falkirk Herald – About 5 o’clock on Saturday morning last Patrick Cullen, 80 years of age, was found dead in the stove at Bonnyside Brickworks. Deceased, a bricklayer to trade, was one of those who built the first kiln on the brickfields of High Bonnybridge. Of an independent nature, rather than resort to the workhouse, he, with the assistance of the old age pension, was for the past few years able to procure a livelihood by hawking. The police, who were notified of the death, had the body removed to Falkirk Mortuary.

21/02/1914 – James Dougall & Sons Limited, Brick manufacturers, Bonnybridge – for sale 200 ordinary shares of £1 each and 100 5 1/2%. Cum pref shares of £1 each; fully paid – Marshall and Hunter Solicitors, Falkirk.

04/03/1917 – Sunday Post – Ejectment notices served on Bonnybridge householders. This morning ejectment notices to take effect at the ensuing term were served on the tenants of Broomhill, Bonnybridge. The property, which consists of twelve houses, was yesterday sold by the Stirlingshire Property and Investment Company to James Dougall & Sons Limited, Bonnyside Brickworks, Bonnybridge for the housing of their own employees. The outgoing tenants are employed in other works in the locality, and as there is little likelihood of a single house being rendered vacant between now and the month of May they will be forced to seek new homes outwith the district. Two of the houses are occupied by the wives and families of soldiers at present on active service.

03/11/1917 – Falkirk Herald – During the storm which raged on Thursday night and early on Friday morning last, a large part of the works of Messrs James Dougall and Sons, Ltd., Bonnyside Brickworks, was damaged. A stalk, 125 feet high, was literally burst open by lightning and about 50 feet of the structure collapsed. Some of the bricks were thrown a distance of 200 yards. Much damage was caused to the machine shop and the machinery also suffered. James Smith, watchman, had a marvellous escape. He was thrown to the ground as a result of the blast and thus escaped injury from the flying bricks. Other workers had just departed from the workshop.

17/11/1917 – Falkirk Herald – Brickwork labourers. A number wanted for firebrick work. Government Class A work. Time or piecework. Minimum 45s. James Dougall and Sons Ltd, Bonnybridge.

09/09/1922 – Yorkshire Post – Company dividend – James Dougall and Sons (Limited), Bonnyside Fireclay Works – Dividend of 7 1/2% on the ordinary shares.

23/07/1924 – Falkirk Herald – A brickworker named Jas, Douglas, residing at 3 Russell Place, High Bonnybridge, pleaded guilty at Falkirk Sheriff Court on Monday to having on 9th July, in Bonnyside Brickworks. High Bonnybridge, assaulted a fellow-worker, by throwing two half-bricks at him, one of which struck him on the body and the other on the elbow. Mr Andrew Hunter, solicitor, Falkirk, appearing on the accused’s behalf, said that Douglas and the complainer worked together. The complainer had accused Douglas in the morning of having circulated tales about him having interfered with some young girls. The row took place as they were going to work in the morning and at dinner time Douglas went to the complainer to ask him what meant by those stories. It appeared that Douglas was working with a spade amongst lime, and he had a brick in his hand, which he shied at the other fellow. The accused was on holiday now and as he was anxious to enjoy his holiday, he hoped his Lordship would enable him to do so by dealing leniently with him. Sheriff Robertson said that according to Mr Hunter’s statement it looked as if the accused had gone back to this man and renewed the altercation which he had earlier in the day. It would have been wiser if had kept away. He did not do so, however, and the result was that he threw a half-brick at the other man. If he had come to fisticuffs he might have received more sympathy. It did not look well to find grown men throwing bricks at one another. A fine of 30s was imposed and paid at the bar.

23/04/1927 – Falkirk Herald – Experienced grate back and chair maker wanted. James Dougall & Sons Ltd, Bonnybridge Firebrick Works, Bonnybridge.

21/01/1931 – Falkirk Herald – Sequel to Bonnybridge Work’s Blaze. The distressing sequel to an outbreak of fire in the Bonnyside Brickworks, High Bonnybridge, early on Monday morning took place at the works on Tuesday, when Donald Stewart, glazier, 52 Mary Street, Laurieston, who was repairing the roof of one of the buildings involved in the fire, fell through and sustained injuries to his head and left leg. He was removed to the Falkirk and District Infirmary, where he was detained for treatment. It appears that Stewart, who is employed by Messrs Daniel O’May & Company, glaziers, Falkirk, was working on the roof of a stove when he fell through the roof, which consisted of asbestos sheets, and landed on the cement floor, a distance of about 12 ft. The Bonnyside Works are occupied by James Dougall & Sons, Ltd., and the fire occurred about 2.30 a.m. on Monday. It was discovered that it had broken out in a stove in which a large number of fireclay spirals had been placed in wooden crates to dry. The flames shot into the air and spread with such rapidity that all the crates were destroyed. Over 100 panes of glass, measuring 6ft. by 2ft., on the roof were broken by the intense heat. The fine was first seen on the top of the gas kiln situated immediately underneath the cement floor of the stove, where bricklayers had been using a scaffold. The entire stove was burnt out before assistance could be got, and the outbreak only lasted for a short period. The damage to the building and material is estimated at £200 and is understood to be covered by insurance.

11/09/1931 – The Scotsman – Brickworks manager killed on the railway – The body of a middle-aged man found lying on the railway line near Camelon junction, was identified yesterday as that of Thomas Love Bernard, Bonnyside House, Bonnybridge. The deceased, who was the manager of Dougall’s Brickworks, High Bonnybridge was returning home along the line when, it is surmised, he was overtaken and run down by a goods train before he could get out of the way.

07/10/1933 – Falkirk Herald – Fireman injured – In the course of his employment at the High Bonnybridge Works of Messrs Dougall & Sons, brickwork fireman named James Hutcheson residing at Cowden View, Bonnybridge was on Monday last severely burned on the eyes. The accident occurred while Hutcheson was engaged in firing a steam boiler and the injury is such that it is feared he will lose the sight of an eye.

Below – 09/01/1935 – Falkirk Herald – Brickworks jubilee. Celebration of 50 years. An interesting function took place in the Bonnybridge Public Hall on Friday of last week when the directors of Messrs Jas. Dougall & Sons, Ltd., firebrick manufacturers, Bonnybridge, entertained approximately two hundred and fifty employees and friends at a tea, social, and dance. The platform party included the chairman of directors, Mr E. G. Smith, Glasgow, whose father, the late Sir J. B. Smith, was a former chairman of the company; Mr R. A. Munro, Tighnabruaich; and Mr G. A. Mitchell, Glasgow, directors; Mr W. Boyd Mitchell, managing director; Miss Mitchell, Miss Munro, Mr Reid, the secretary, the works manager, staff, and friends. Mr W. Boyd Mitchell, in welcoming those present, said that on the occasion of the company’s jubilee celebrations, it was his privilege and pleasure to welcome them all there that evening. Referring first to their guests, he would like to assure them of their hearty welcome on that important occasion, and they hoped that their evening here would prove to be an enjoyable one. Their presence was doubly welcome, first for their company, which they were certain to enjoy, and, secondly, for the fund which had accumulated from the price paid for their tickets. This sum of money the directors had decided to hand over to the Dougall Welfare Club for the building repair fund. (Applause.) It was his privilege also to welcome those who were employees of the company. They must all be feeling rather impressed to think that the company had just completed the 50th year of its existence. He also wished to refer to the company itself, whose jubilee they were there to celebrate. They had passed through some bad years recently when the depressed state of industry made anxiety and worries their daily bread, and many of them had had to suffer from periods of unemployment or short time. He was proud of the way that his staff and employees faced up to this trying period, and their courage and spirit during these trying times strengthened his own spirit and resolution to win through to better times. In his 11 years’ association with the company, he had never had to fight a lonely battle to keep the name of Jas. Dougall & Sons, Ltd., where it should be in the industry. The loyalty and cooperation of the staff and employees had made his work a pleasure and assisted him to overcome many difficulties of modern competitive business. It was good to see the works again on full production, and the credit for this was due in a large part to themselves, as they could not yet say that trade generally had returned to the comparatively satisfactory state of five years ago It amazed him when he looked back also on the changes which had taken place in the firebrick industry during the last ten-fifteen years. Furnace temperatures in almost every industry had been increasing enormously, and better and better firebricks had been the constant cry from every direction. He was proud of their own achievements during these years. Their quality had improved out of all recognition and this he attributed to three main causes, firstly, a better scientific knowledge of what constitutes a first-class product and how to obtain it; secondly, an improvement in the machinery and other apparatus required to produce a quality article; and thirdly, and perhaps most important of all, better understanding on the part of the staff and employees of the care and knowledge that was required to produce a quality article. (Applause.) These changes in methods and standards had not been achieved without difficulties and trials for all of them. New methods meant new techniques and changes which could not always be to the advantage of every employee. But let him assure them in all earnestness that the venerable company whom they were honouring, consisting of building plant, machinery, and several hundred individuals, must, to be healthy and prosperous, contain no out-of-date methods, no shirkers interested only in the Friday pay envelope and one united purpose. Methods and requirements in their industry would continue to change in the future as they had done in the past but looked forward with confidence to the future of that particular company, whether good or bad times were in store for them, as he had confidence in the ability and desire of the staff and employees to set themselves intelligently and successfully to whatever problem may confront them. At present they were blessed with a full order book and prospects of a continuance of better trade. (Applause.)

Mr J, Arthur Reid, C.A., the secretary of the company, gave a short address recounting briefly the history of the company and told how the business was founded in 1884 by Mr James Dougall and his sons, formed into a private limited company in 1886, and floated as a public limited company in 1907. The successive chairmen of directors had been Mr James Dougall, the late Dr James Russell, a former Moderator of the Church of Scotland, the late Sir J. B. Smith, and at the present time, Mr Edwin G. Smith. The company owned modern works premises and plant, the estates of Bonnyside and Bonnyhill, and many dwelling houses which were occupied by the employees. In closing, Mr Reid expressed the wish of all present that the second fifty years would be as fruitful as the fifty years now passed.

Mr Smith, in the course of a brief address, referred to past officials and employees and went on to say that they had to look to the future, for it was the next fifty years that was going to matter. If a book about the firm was written he would like to see a chapter headed “Success.” (Applause). Mr Munro, who also spoke, said he could well remember the time he paid his first visit to Dougall’s Works and the ramshackle appearance they presented. That was a little over twenty years ago. He was sure that those who remembered the works at that time would be struck with the great contrast today. Looking back over the years and considering the very difficult times they had come through, and the difficulties that had to be overcome, due to the war period and its afterwath of depression, it seemed to him that they had not done so very badly. There certainly had been great change for the better, and not only had the technical equipment and the appearance of the works been greatly improved, but they were also turning out a higher standard quality of goods. Mr Munro went on to pay tribute to the managing director, Mr Mitchell, who, he said, was a person possessing ambition and the youthful enthusiasm to excel. Mr Mitchell desired to have the best-equipped works in the country, and to put on the market the best quality of goods. It was a matter for great satisfaction that during all the years they had been associated with the Dougalls, they had never any serious trouble with the workpeople. At no time had the directors been indifferent to the welfare of the employees, and there had always been the best relations existing between them. (Applause.) He thought there was no reason to doubt that Mr Mitchell’s ambitions would be realised, and they could look forward to a greater measure of prosperity than they had ever enjoyed in the past. He concluded by stating that the directors welcomed the opportunity of meeting with their employees in a social capacity.

The final speaker was Mr George Mitchell who said it was a pleasure to hear of the cordial relations existing between the management, the staff, and the workers of Dougalls. They could not have success unless capital, management, and workers realised common responsibility. The company felt a responsibility towards those they employed, and the employees should feel a responsibility to the company. No business could be inefficiently managed without injuring the country itself, and they, therefore, had a common responsibility to each other and to their country. Times had changed since a man could say that he lived by himself, and no one had any right to interfere with what he did. They all felt their obligation to do the best they could to carry on their business.

During the course of the evening, an enjoyable programme of solos and recitations was contributed to by Miss Cogan, Mr Bulloch, Mr Colquhoun (accompanist), and Mr Hannah (elocutionist.) Thereafter the company engaged in dancing, the music being provided by Smith’s Elite Orchestra, while the duties of M.C. were very capably discharged by Mr A. Higgins. Votes of thanks were proposed to the guests by Mr Bennie; to the artistes by Mr McCluskie; and to the directors by John McPhail, works manager.

08/06/1935 – Falkirk Herald – The employees of Messrs James Dougall & Sons, Ltd., met in a social capacity in the Welfare Hall, High Bonnybridge, on Friday evening of last week, to do honour to Mr Duncan Ferguson, works foreman, who has retired after having served the firm for 21 years. ln his opening remarks, Mr John M Phail, manager, who presided, expressed his gratification that such a large number had attended, and hoped that the evening would prove an enjoyable one for all. He also intimated an apology from Mr Boyd C, Mitchell, managing director, who was prevented from being present by his father’s indisposition. A splendid tea was then served by a voluntary party of interested ladies, whose service and arrangements were deserving of the highest praise. After tea, the chairman, at the close of a felicitous speech, and on behalf of the firm and employees, asked Mr Ferguson to accept a wallet of treasury notes, as a token of their profound esteem, and as an earnest of their good wishes for a long and happy retirement. The gift, he said, was also a mark of appreciation of the faithful service he had given to the firm. For a long time, his wide experience and expert knowledge of the routine would be missed in the works, as Mr Ferguson himself would be missed by all. On accepting the gift the recipient’s son, Mr W. R. Ferguson said he was touched by the kindly feelings which prompted it. It gave him the greatest pleasure to know that his father had been held in such deep regard by those with whom he had worked. On his father’s behalf, he thanked them all most heartily, not only for the valuable gift but also for the spirit of sincere friendship that had led to the presentation. The remainder of the evening was happily spent, songs being rendered by the Misses Gavin, Cullen, and Stocks, and Messrs J. McDonald, J. Nolan, and J. Martin. After the customary votes of thanks had been accorded to Mr McPhail to the ladies who had served the tea, and to Messrs Coyne and Mills, who had carried through the arrangements, the whole company joined in singing “Auld Lang Syne.”

19/06/1937 – Falkirk Herald – Motor excursion. Last Saturday the employees of Messrs James Dougall & Sons, Ltd., brick manufacturers, held their annual summer outing, when a company of more than 200 left High Bonnybridge at 8 a.m., comfortably accommodated in seven of Messrs Alexander’s motor coaches. Proceeding via Kilbride, a non-stop journey was made in weather which, although dull and rather cloudy, was dry and bracing. On arrival at Large, the pre-arranged destination, the trippers dispersed on tours of sightseeing. shopping, and sea-shore attractions, the water-front easily claiming the most attention. At eight o’clock the coaches were again boarded for the homeward journey, High Bonnybridge being reached about 10.30 p.m.. after an excellent day’s outing. Mr David Ferguson, Welfare secretary, and his committee are to be congratulated upon the success that attended the excursion.

03/07/1937 – Falkirk Herald – Thomas Connell. 23 years of age, appeared from custody at Falkirk Sheriff Court on Saturday morning and admitted two charges of theft. The complaints to which he pleaded guilty were that at the house at 5 Brodie Street, Falkirk, he stole £1 in money, and from Bonnyside Brickworks. High Bonnybridge, he stole a bicycle. Mr J. G. Morrison, Procurator Fiscal, said the accused had been lodging at 5 Brodie Street. The tenant had left some money in one of the pockets of his trousers and on Thursday. 24th June, discovered that the money was missing. The same day the accused visited Bonnyside Brickworks, and after he had gone it was discovered that a bicycle was stolen. The police were informed, and at Bonnybridge Connell was found in the vicinity of the Employment Exchange with the cycle. The sum of £1 was also found in his pocket. Hon. Sheriff-Substitute James Allan – Was the bicycle a valuable one? Mr Morrison – The value is given as £8. The machine has been recovered, of course. The accused was fined £2, with the option of 14 days’ imprisonment, a fortnight being allowed for payment of the fine.

Below – 12/11/1937 – The Scotsman – Reduction of the capital of James Dougall & Sons Limited from £70,000 to £50,0000. (25/08/1937 – The Scotsman – Also refers).

1938 – List of mines in Scotland – Jas. Dougal & Sons Ltd., Bonnyside Firebrick Works, Bonnybridge. John McPhail manager. Thomas Boak, under manager. 48 employed underground and 34 employed above ground.

Below – 08/01/1938 – Falkirk Herald – James Dougall and Sons social outing.

08/11/1939 – Falkirk Herald – Office boy wanted, preferably resident in Bonnybridge; superior, intelligent and smart. Apply, by letter only, to the Secretary, James Dougall & Sons, Ltd., Bonnybridge.

Below – 01/11/1941 – Falkirk Herald – Disgruntled employee damages bricks in the gas kiln buildings. John Gavin, Lochview, High Bonnybridge, was before Sheriff Hendry at the Falkirk Sheriff Court on Monday charged with having, on 24th September, in the gas kiln building, Bonnyside Works, High Bonnybridge, occupied by James Dougall &; Sons, Ltd., fire brick manufacturers, maliciously upset a barrow containing 26 dry green bricks whereby the bricks were destroyed. He pleaded guilty. Mr A. G. Anderson, Procurator-Fiscal, said this was a somewhat extraordinary charge. Accused, who was employed at the works, made a certain demand on the management, requesting to be put on a time job instead of a piece job, In accused’s idea, he did not get the satisfaction he wanted, and he said to the secretary of the company: “I will force you to give me the sack.” With that, he upset a barrow of bricks, and a number of the bricks were destroyed. It was sheer bad temper on the accused’s part. If this sort of thing was allowed, there would be no discipline in the works at all. The accused was 18 years of age, and the damage he caused was about £1. A fine of 40s was imposed.

03/10/1942 – Falkirk Herald – Wanted. Office Boy, resident in Bonnybridge or district. Application by letter only to the Secretary, James Dougall & Sons, Ltd., Bonnyside Firebrick Works, Bonnybridge.

06/10/1943 – Falkirk Herald – Patrick Moran, 18 Waverley Crescent, High Bonnybridge, was before Sheriff Hendry at Falkirk Sheriff Court on Monday charged with having, along with another man who did not appear, in the moulding and drying stoves of James Dougall & Sons, Bonnvbridge Works, High Bonnybridge, maliciously damaged and broken 18 electric lamp globes and 7 bakelite lamp holders by throwing at them pieces of brick clay and a brick stamp. The accused pleaded guilty. Mr A. G. Anderson said the offence was probably irresponsibility more than anything else. The accused was 20 years of age. When challenged about it he admitted the offence quite frankly. He broke them with lumps of clay and broken bricks. The accused was fined £5, with the option of thirty days.

Below – 1943 – Bonnyside Clay Mine.

Below – 1944 – 1967 – Bonnyside Works.

09/12/1944 – Falkirk Herald – Theft and reset of petrol. Thomas Connell, in custody, pleaded guilty to having, between 24th and 28th November, broken into the garage at Bonnyside Brickworks, High Bonnybridge, occupied by James Dougall & Sons, Ltd., and stolen a drum containing 10 gallons of petrol valued at £1 1s.

07/04/1945 – Falkirk Herald – Wanted. Office Boy resident in Bonnybridge or District. Application, by letter only, to the Secretary, James Dougall & Sons, Ltd., Bonnyside Fire Brick Works, Bonnybridge.

1947 – James Dougall and Sons took over the Whiterigg Fireclay Mine, East Whitburn. They sold 50% to the Douglas Fireclay Company. Source Kenneth W Sanderson.

18/01/1947 – Falkirk Herald – Clerk required with book-keeping experience. Application, giving details of experience and salary required, to the Secretary, James Dougall & Sons, Ltd., Bonnybridge.

12/07/1947 – Falkirk Herald – An employee of the Bonnyside Brickworks, High Bonnybridge, discovered on a Saturday morning that a pane of glass in a back window to the office had been broken. On making investigations it was found that 1 1/2 cwts. of sugar, 12 lbs. of tea and a clock had been stolen. This story was told before Hon. Sheriff-Substitute James Allan at Falkirk Sheriff Court on Tuesday, when James Sinclair, Joseph Moran and William Ritchie, all from custody, pleaded guilty to having, between 4th and 5th July, broken into the office at the Bonnyside Brickworks, and stolen the sugar, the tea, and the clock. Mr R. W. Dean, solicitor, Falkirk, prosecuting, said that the premises were properly secured on the Friday evening. When one of the employees entered the office on the Saturday morning she found that one of the panes glass in the back window had been broken and that the thefts had taken place. The police were informed, and enquiries were made. The three accused were traced and admitted the theft. Moran and Ritchie were both employed in the works where the house-breaking took place. Sinclair was 46 years old, Moran 22, and Ritchie 24 years old. Mr Dean said he thought it was apparent that Moran and Ritchie knew where the goods were kept, and that Sinclair had accompanied them. All the articles stolen were recovered. Sinclair said: “If I get a chance it will never happen again. I was very silly doing the thing I did.” Moran, who admitted three previous convictions, was sent to prison for 30 days. Sinclair, who had one previous conviction, was fined £5, with the alternative of 30 days’ imprisonment, and Ritchie was fined £3, with the alternative of 20 days’ imprisonment. Fourteen days in which to pay the fines were allowed.

17/04/1948 – Falkirk Herald – Maintenance engineer wanted for brickworks. Apply to Messrs James Dougall & Sons Ltd, Bonnyside Firebrick Works, Bonnybridge.

04/09/1948 – Falkirk Herald – Wanted. Handyman capable of carrying out repairs to estate property. Apply by letter to the Secretary, James Dougall & Sons, Ltd, Bonnyside Firebrick Works, Bonnybridge.

20/05/1950 – Falkirk Herald – Fitter required with experience in maintenance of bricklaying plant, A.E.U. rates and conditions. Apply to Manager, James Dougall & Sons, Ltd., Bonnybridge.

09/06/1951 – Falkirk Herald – Fitter required for maintenance work in firebrick works; must have experience of Bradley & Craven machines: house available. Apply to James Dougall & Sons, Ltd., Bonnybridge.

22/09/1951 – Falkirk Herald – Pattern maker required for firebrick works: trade union rates and conditions of employment; house may be available. Apply James Dougall & Sons, Ltd., Bonnyside Firebrick Works, Bonnybridge.

08/12/1951 – Falkirk Herald – Clerk required for sales office; age about 22 years: experience of orders, progressing and despatch an advantage: wage for age scale. Apply, giving full details of experience, to the Secretary, James Dougall & Sons, Ltd., Bonnyside Firebrick Works, Bonnybridge.

22/12/1951 – Falkirk Herald – Office boy required, age 15-16 years, good education and appearance. Please state full particulars in application to the Secretary, James Dougall & Sons, Ltd., Bonnyside Firebrick Works. Bonnybridge.

c. 1953 – James Dougall bought out the 50 % share of the Whiterigg Fireclay Mine, East Whitburn as owned by the Douglas Firebrick Company. The clay from the Whiterigg clay mine had a low iron content and was used in the manufacture of saggars. Source Kenneth W Sanderson.

15/05/1953 – The British Clayworker – New Acquisitions by Ceramic Holdings Ltd., as of March 31st, 1953, have acquired 98.2 per cent of the issued share capital of James Dougall & Sons Ltd., firebrick manufacturers, Bonnybridge, and the whole of the issued share capital of the Diamond Clay Co Ltd., Stoke-on-Trent, who are specialists in the manufacture of refractories for the pottery industry. The two companies will continue to trade independently under their present board of directors and it is intended later to apply for a stock exchange quotation for the shares of the new holding company. The directors of the Ceramic Holdings Ltd. are Mr W. Boyd Mitchell, M.B.E., Chairman and Managing Director of James Dougall & Sons Ltd, and Chairman of the Diamond Clay Co. ltd.; Mr Alan D. Cuthbert, Shipowner; Mr G. N. Hodson, M.B.E., Chemical Stoneware Manufacturer; Mr Donald. L. Platt, Floor Tile Manufacturer; Sir A. Murray Stephen, M.C., Ship-builder; Mr C. R. F. There fall, M. C., firebrick manufacturer. The board of directors includes Mr Threfall, Mr Hudson and Mr Mitchell three past presidents of the British Ceramic Society showing that the board as a whole, in addition to industry experience, are conversant with an unusually wide range of products in the ceramic industry itself.

16/05/1953 – Falkirk Herald – Clerk wanted, experienced in costing or wages: good salary and prospects; canteen facilities available. Apply by letter, in the first instance, stating particulars of previous employment, to Secretary, James Dougall & Sons, Ltd. Bonnyside Firebrick Works, Bonnybridge.

03/10/1953 – Falkirk Herald – Clerk wanted; Experienced wages and P.A.Y.E.; canteen facilities available. Apply by letter to the Secretary, James Dougall & Sons, Ltd., Bonnyside Firebrick Works, Bonnybridge.

01/05/1954 – Falkirk Herald – Blacksmith required, experienced and accustomed to brickwork machinery. Apply Chief Engineer. James Dougall & Sons. Ltd., Bonnyside Firebrick Works, Bonnybridge.

27/03/1954 – Falkirk Herald – Telephonist. 16-18 years, required for firebrick manufacturers, some clerical experience an advantage: canteen facilities available. Apply by letter to the Secretary, James Dougall & Sons Ltd. Bonnyside Firebrick Works, Bonnybridge.

22/05/1954 – Falkirk Herald – Bonnybridge. For sale. Semi detached house. Larbert Road, containing two public rooms kitchen, downstairs: two bedrooms, bathroom, upstairs; Main’s gas cooker and immersion heater; assessed rental. £23; feu-duty £1 16s 6d per annum. For cards to view apply to the Secretary James Dougall & Sons Ltd, Bonnyside Firebrick Works Bonnybridge.

05/06/1954 – Falkirk Herald – Wanted. Sales clerk with experience in estimating, required. Apply in writing to the Secretary, James Dougall & Sons, Ltd., Bonnyside Firebrick Works, Bonnybridge.

22/01/1955 – Falkirk Herald – Maintenance engineer with experience in brickwork or colliery machinery, required. Apply Chief Engineer, James Dougall & Sons, Ltd., Bonnyside Firebrick Works Bonnybridge.

28/01/1955 – The Glasgow Herald – Refractories Placing – Ceramic Holdings Ltd., capitalised at 250,000 in ordinary shares of 10’s each, of which there are in issue or to be issued fully paid 400,000 shares, are applying to the London and Glasgow stock exchanges for permission to deal and for a quotation for the whole of the issued Ordinary shares. The company have no debenture stock, mortgages, or loan capital outstanding. Incorporated in February 1953, the company acquired the issued share capital of the subsidiaries, James Dougall and Sons, Ltd., formed in 1907, and the Diamond Clay Company, Ltd., formed in 1933, as at March 31, 1953. James Dougall and Sons own works at Bonnybridge, Stirlingshire and manufacture heat-resisting firebricks and other refractories for use in iron and steelworks and coke oven plants, and for other similar purposes. The Diamond Clay Company own works at Hartshill, Stoke-on-Trent and manufacture specialised refractories for the pottery industry so that the two businesses are to some extent complementary. To effect certain improvements to the Dougall works, the company have issued 52,000 Ordinary shares of 10’s each at 10’s 7 1/2d per share. All the works are fully employed. An interim dividend of 5 per cent. (Previous year 3 per cent.) was paid on January 14 last, and on the assumption that the profits for the current year will be approximately those for the year ended March 31, 1954 – namely. £73,450 – it is intended to recommend a final dividend of 5 per cent., payable towards the end of July. It is expected that full particulars will be advertised on Monday and that dealings will begin on Thursday. February 3. Brokers to this placing are Cazenove and Co., Stock Exchange, London and S. M. Penney and MacGeorge, Glasgow.

28/05/1955 – Falkirk Herald – Young man with accountancy training and experience of book-keeping and preparation of accounts, required to assist company secretary; good prospects and salary offered to a young man with intelligence and the ability to work accurately. Apply in writing, giving particulars of education and experience to the secretary, James Dougal & Sons, Bonnybridge.

02/07/1955 – Falkirk Herald – Invoice and despatch clerk required immediately; National Service completed; experienced in refractories trade preferred, but not essential; canteen facilities available. Apply James Dougall & Sons, Ltd., Bonnyside Firebrick Works, Bonnybridge.

Below – 13/08/1955 – Falkirk Herald – Wash machines for brickwork. Mr W Boyd Mitchell, who has been managing director at Dougal’s Brickwork, High Bonnybridge for 25 years, marked the occasion of his semi-jubilee by presenting two electric washing machines for the use of the employees and employees wives. The picture shows a demonstration in progress.

Below – c.1960 – Bonnyside Brickworks.

1962 – Dyson Refractories take over the site.

Below – March 1964 – Refractories Journal – James Dougall and Sons Ltd/Dyson Refractories were advertising ‘Borgestad -07’ bricks as part of their product range. It is entirely possible that Borgestad bricks were stocked and sold by Dougall in a cross-company agreement.

01/07/2015 –

RHI Magnesita Hillview Road, High Bonnybridge, Scotland, United Kingdom are currently operating on what was previously known as the “West works” in Dyson’s time and prior to that, James Dougall. Dyson produced bricks in the “East works” and in the West Works, Graphite/Alumina Isostatically pressed products for the control of molten steel in the continuous casting process in steel mills. Dyson sold the ISO (Isostatic products) business to Foseco in the early ’90s. Foseco then developed the manufacturing process and gained a significant market share in Europe. In 2008, RHI purchased the operation from Foseco (who in turn sold out to Cookson/Vesuvius). The operation in Bonnybridge no longer produces isostatic products, this is done at the RHI site in Clydebank. RHI Bonnybridge produces the graphite/alumina granular material which is shipped to Clydebank for pressing/heat treatment/kilning/finishing. What is left of the East works is no longer owned by Dyson but a local dairy farmer.

Below – Unknown date – James Dougall Fire clay Works from the air.

Below – A dense unmarked brick found in abundance on the Bonnyside Works site. Most likely a James Dougall or Dyson product.

.

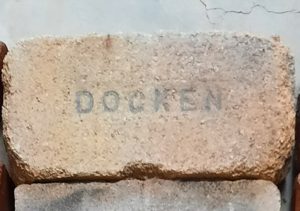

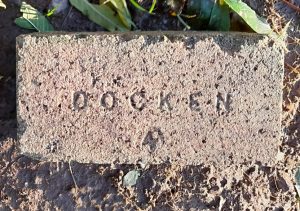

Below – The Scottish Industrial Archaeology Survey published a report in 1985 entitled ” A survey of Scottish brickmarks. During the compilation of this report in which the survey officers visited working and derelict brickworks sites, many items of interest were donated or found. Many of these items were thereafter donated to the National Museum Scotland. The item below is one of these items. A brass stamping plate marked ‘Docken’.

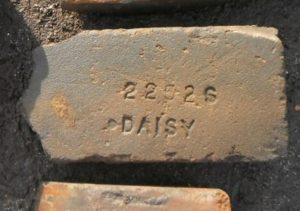

Below – a Similar brass stamping plate marked ‘Dougall’.

Below – Information – British Geological Survey. Ganister from the Top Ganister Bonnybridge Fireclay Works, Stirlingshire

Ganister from the Top Ganister Bonnybridge Fireclay Works. A number of works and mines were active in the Bonnybridge area. They worked and processed the Carboniferous, Millstone Grit Upper Fireclay, a series of fireclays and ganisters.

The works at Bonnybridge included James Dougal and Sons Limited working the Bonnyside Pit and the Bonnyside Fireclay Works (the only pit recorded working the ‘Top Ganister’); the Bonnybridge Silica and Fireclay Company working the Drum Mine; Dykehead Ganister and Firebrick Company Limited working the Dykehead Mine and the Glenyards Fireclay Company working the Glenyards Mine.

The ganisters were usually crushed at the works and sold in the ground condition to steel manufacturers for lining converters etc. Mixtures of ground ganister and fireclay were also supplied to foundries and chemical works.

Below – An undated brand reference sheet from a Dyson Refractories catalogue.