Gartcraig brick found in Australia

— 05/12/2023Found by Joe Fletcher at “Turonville” in Tarana, NSW Australia. The property is a farm dating back to the 1850s. Gartcraig Fire Clay Works, By Millerston, Glasgow. . . . .

Newark Brick and Tile Works, Tipperty, Ellon, Aberdeenshire.

Tipperty Tileworks, early 20th century. A most interesting complex, producing tile field drains. There is a range of four circular kilns, enclosed in a 2-storey building, with 3 circular-section, iron-bound chimneys. The floors above the kilns are used for drying the ‘green’ pipes after extrusion, as are pantile and asbestos roofed single-storey drying sheds. The pug mill and extrusion plant, conveyors and other machinery are driven by a Ruston & Hornsby 2-cylinder horizontal diesel engine, size 8 class HR6, works no. 351331. There is a 2ft (0.6m) gauge railway, in two sections, linking the works with the claypit. (1977). It comprised of four round downdraught (intermittent) kilns and was mostly demolished by 1981.

1849 – William Forbes starts brick production at Newark.

05/9/1851 – Edinburgh Gazette – John Riddoch, sometime brick and tile maker at Macduff, and afterwards employed at the brickwork, near Ellon, occupied by William Forbes, and

resident in said Parish, afterwards Labourer at Portobello, and latterly at Tipperty, in the County of Aberdeen, and presently Prisoner in the Prison of Aberdeen, has presented a Petition to the Sheriff of Aberdeenshire, craving decree of Cessio Bouorum, and interim liberation, and protection from the diligence of his Creditors; and the said Sheriff has fixed Wednesday the 8th day of

October next, at 12 o’clock noon, within the Court-House, Aberdeen, for the public examination of the Petitioner, at which time and place all his Creditors are required to attend. Aberdeen, September 3, 1851.

04/11/1851 – Fettercairn – At the late meeting of the Fettercairn Farmers’ Club, Sir John Forbes exhibited specimens of a very ingenious fluted brick and gutter tile for byre floors, invented and registered by Mr Forbes of Newark Tileworks, Ellon the object of which was to save litter, by having grooves only half-inch wide at the top, and widening below, running at intervals of five inches from half-way up the stall, and opening by corresponding notches into the gutter brick on which the animal lies with much greater comfort on boards, and a moderate portion of litter, which, in practice, is found to prevent the dung from closing up the grooves, lasts a great deal longer, being kept quite dry. These bricks which can be sold in Aberdeen at 11s 6d per 100-70 to 80 being sufficient to lay a double stall-have been much commended by the Directors of the Highland and Agricultural Society. They excited much interest at the meeting, and several of the members, as well as the Chairman, signified their intention of ordering some for a trial immediately.

27/11/1851 – Falkirk Herald – Highland and Agricultural Society … Mr Hall Maxwell wished before the commencement of discussion to call the attention of the meeting to specimens of grooved brick for laying the floors of cattle stores, invented and manufactured by Mr Forbes of Newark brickworks near Ellon in Aberdeenshire. Their peculiarity consisted in the brick being slit in the surface and grooved in the centre, the grooves communicating with a larger brick of similar construction, on the principle of a main drain, received their contents and formed the grip or gutter. He mentioned that he had received from Sir John Forbes and various practical farmers in Aberdeenshire, statements certifying the advantages of the invention in point of cleanliness, the economy of litter and comfort and he understood the bricks were sold at the kiln at 8 shillings per 100, 160 being sufficient for 4 animals.

Below – 24/11/1852 – North British Agriculturist – Forbes’s registered drain pavement.

15/03/1854 – Aberdeen Press and Journal – Newark Brick Work, Ellon – Reduction in prices – A complete assortment of all sizes of drain pipes on hand, of excellent quality, being all carefully re-selected. The prices are, till further notice, reduced 10 per cent, on all sizes under inch bore; they (the 2 1/2 inch) are also reduced upwards of 5 per cent. Hereafter no discount will be given on drainage materials. The Subscriber takes this opportunity of thanking the public for the liberal support he has received, and trusts by still further improving the quality of his stock, to merit a continuance of their favours. He would draw particular attention to his large hollow bricks, manufactured so cheaply that bricks to build a wall 9 inches thick, cost only 1s 6d per square yard; they are particularly suitable for garden walls and small cottages— 10 yards are one cartload. The dwelling-house at Newark was built of them 4 years ago (walls 13 inches thick), and is both warm and dry, and the experiment has been in every way satisfactory. He has succeeded in producing a drain pavement for horses’ stalls, which bids fair to rival his celebrated flooring for cattle, keeping the horses drier and cleaner than any other causeway, with half the litter. They are highly recommended all farmers, stablers, and coach proprietors who have tried them. They are laid and may be seen, in nearly all the stables connected with the Banks of Ythan Coach. Bricks, tiles, drain pavement, chimney cans, &c. &c. will be on hand in a few weeks. N.B. —No Inspector, or other parties, ever remunerated for recommending the stock. 14 March 1854, Wm. Forbes.

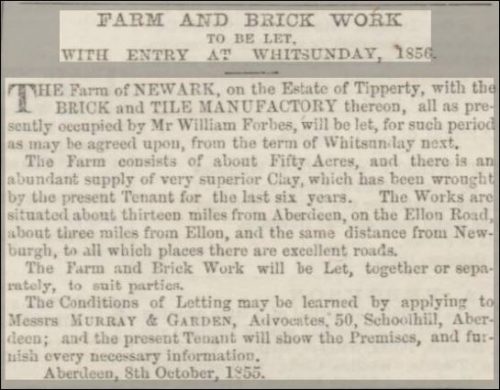

Below – 24/10/1855 – Aberdeen Press and Journal – Newark Brick and Tile Works for let. William Forbes.

28/03/1856 – Edinburgh Gazette – The copartnery between the subscribers, under the firm of William and James Forbes, Brick and Tile Manufacturers, Newark, Ellon, Aberdeenshire,

has been dissolved by mutual consent. Witness our hands this 26th day of March 1856. Jas Forbes.

28/04/1858 – Aberdeen Press and Journal – Drain Pipes, &c., at Tipperty. There are on hand at present, the usual sizes of pipes, from 5 inches to 1 1/4 inches in diameter; Drain pavement for cattle and horses stalls; hollow bricks for building walls, of 5, 6, and 9 inches thickness, etc. Pantiles and bricks will be ready for delivery early in May. All of a superior quality. The hollow bricks cost for a 9-inch wall about 2s per square yard; or the subscriber will contract for building small cottages and outhouses, affording lime and workmanship, at from 2s 6d to per square yard. Liberal discount for cash, first Ellon Market after delivery. William Forbes. Newark Brick Work, Ellon, 26 April 1858.

1865 – 1871 – ScotlandsPlaces – Newark. Applies to a small farm steading, and brickworks, situated near the county road leading from Aberdeen to Ellon &c. property of John Turner Esqr. Turnerhall Ellon Parish, Aberdeenshire.

Below – 1866 – Newark Brick and Tile Works.

1867 – William Forbes, brick and tile maker, Tipperty, Logie, Buchan.

Below – 31/07/1868 – Buchan Observer – Highland and Agricultural Society Show.

25/04/1876 – Banffshire Journal – School Board Elections – Candidates … George Gray, Westfield Brickworks, Auchmacoy, William Forbes, Tipperty Brickworks …

1886 – William Forbes, Newark Brick and Tile Works, Logie, Buchan, Ellon.

29/05/1888 – Peterhead Sentinel – Peterhead – Sale of a wreck – The derelict Norwegian schooner De Tvende Brodres Minde of Farsund was sold by auction at Peterhead on Friday by Messrs Leask and Co, commission agents, and was purchased by Mr William Forbes, Newark Brickwork, Ellon for £16.

Below – 10/08/1888 – Aberdeen Free Press – William Forbes’ new yacht – The ‘Glide’.

26/03/1895 – Banffshire Journal – Nominations for Parish Councillors … Foveran – William Forbes, retired brick and tile manufacturer (Note – SBH – I assume Willam Forbes Senior).

Below – 1899 – Newark Brick and Tile Works.

Below – 02/09/1899 – Peterhead Sentinel – Advert for William Forbes & Sons, Newark Brickworks, Ellon.

1901 – Directory of Clayworkers – William Forbes & Sons, Newark. Brick and Tile Works, Logie, Buchan, Ellon, Aberdeenshire.

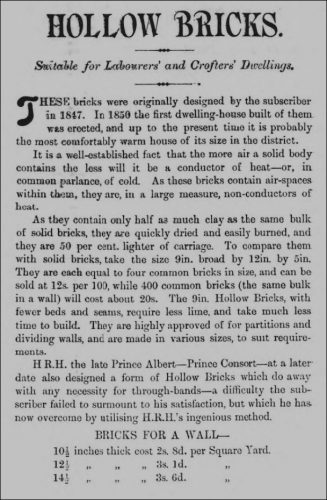

Below – 19/07/1902 – Peterhead Sentinel – The Highland and Agricultural Society’s Show … One of the most interesting stands at the show was that of William Forbes, Newark Brickwork, Ellon, who had a capital exhibition of the various varieties of brickwork, for the manufacture of which he has such a reputation. His exhibits included specimens of his patent drain paving for cattle stalls; half collared impervious pointed pipes for conveying water purity, or for sewage; improved segment pipes for building culverts, mill races, and for lining walls; hollow bricks now so largely used, owing to their utility combined with small cost, for building dividing walls in dwellinghouses, and the outer walls of cottars and crofters houses, barns, byres, sheds, etc; Albert bricks, the invention of the late Prince Albert, for building cottages; as well window ribats, corners, etc., for Albert bricks. Mr Forbes’s pavement for bullock stalls is said to be found exceptionally satisfactory for the purpose. Forbes himself, now in his seventy-sixth year, was in attendance the stall, and by a series of leaflets, as well as his interesting explanations of his wares, contrived to make Stall 154, a source of no small attraction …

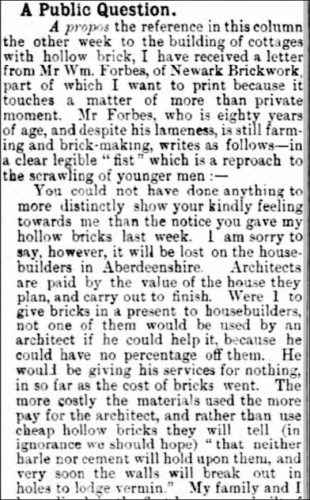

26/07/1902 – Peterhead Sentinel – Bricks and tiles – Talking of the cattle show, the one genuinely interesting feature of the industrial display was the presence, as reported last week, of Mr William Forbes, the veteran brickmaker of Newark, Ellon, and one-time of Invernettie, Peterhead, as was his father before him. Mr Forbes who is in his seventy-sixth year had practically retired from brick-making but recently, for some time prior to the death of his son (who formerly managed the brickwork at Newark), Mr Forbes had returned to active service. In spite of his years and his lameness, he last year, as I pointed out at the time, took another nineteen years lease of his farm; and last week he attended the show in person once again, and did very well. Among other orders, he got one from a French gentleman for drain pavement for the stalls of bullocks, the Ellon clay going to a model farm in the department of Loir-et-Cher. From all I can gather, these goods, of which Mr Forbes is the inventor and maker, are not nearly well taken up as they ought to be. The hollow bricks, in particular, make warmer cottar’s houses than solid bricks or stones; they are cheaper; being larger in size, a given area can be built of them more rapidly than with ordinary bricks; while less lime is used in building, and of course, the bricks are lighter in transport. The trouble is that, as is said, a number of architects have an interest in certain brickworks, and in their specifications, the bricks of that particular concern are always specified, and even a better and dearer brick is not allowed to be substituted. I like the idea of our old friend at Newark, then, selling his baked clay to the French.

Below – 26/07/1902 – Peterhead Sentinel – William Forbes advert and reference to the hollow brick patent of H.R.H Prince Albert.

.

.

Below – 19/07/1904 – Buchan Observer – Royal Northern Agricultural Society Show, Aberdeen.

05/11/1904 – Peterhead Sentinel – Interesting reminiscences of Mr William Forbes – Mr Annan and Mr Havelock addressed a political meeting in Tipperty School near Ellon on Wednesday night. Mr William Forbes, Newark, who presided said in raising money to meet the enormous expenditure on the army, navy, interest on national debt, wars, etc., the Tory party had always favoured the method of indirect taxation, that was, putting duties or taxes on articles of consumption, in place of direct taxation, like the income tax, so that a man had great difficulty in ascertaining the exact amount of his contribution to the national revenue … Roofing tiles paid a duty of 7s per 1000, and years afterwards when he (the speaker) commenced to make bricks to build his first kiln in 1849 he had to give notice to the exciseman of his intention, submit his moulds for measurement, and if in any degree over the Government standard, double duty was charged on the bricks. The gauger visited the work twice a week to count the bricks made, and to facilitate his work they had to be built in exactly equal rows. When the collector came to Ellon he met him to pay 5s 10d per 1000 for all bricks in made whether saleable or lost by bad weather …

10/06/1905 – Peterhead Sentinel – Buchan is understood to be running short; clay for baking purposes; but surely this only means that there is a lack of prospecting for clay. In any case, my old friend Mr William Forbes down at Newark is still making large quantities of hollow bricks, and would fain make and sell more. His hollow bricks do not use up so much clay as does the solid brick, while on the other hand, a house made of hollow bricks keeps a more equable temperature than a jerry-built stone house, the hollow bricks being non-conductors of both of heat and cold. This is by way of being an advertisement of Forbes Hollow Bricks, and the good old Bricker is welcome to it; but that is less my intention than to see ranges of nice brick cottages and villas stretching out along the South Road to Mile-End, the West Road to Orange, the Windmill Road to the Toll Bar, and the North Road as far as you please.

Below – 01/07/1905 – Peterhead Sentinel – Letter from William Forbes to the newspaper regarding hollow bricks.

.

Below – 19/07/1905 – Aberdeen Press and Journal – Advert for Newark drain pavements.

Below – 20/07/1905 – Aberdeen Press and Journal – William Forbes, Newark. Surrounded by structures of brickwork at Stall 28, the well-known figure of William Forbes Newark is discovered immediately to the left on entering the show yard. In this year of short crops’ in many quarters, Forbes is desirous of directing the particular attention of farmers to his drain pavement, which was patented as far back as 1851. It claimed for this pavement that it gives less work in keeping the cattle clean and dry and that although the cattle enjoy a full and comfortable bed, that bed lasts so long that much litter is saved. No water is visible within byres laid with the drain pavement and it forms a durable permanent floor, which after 30 to 50 years of use is serviceable as ever. Mr Forbes exhibits, as usual, his bricks for building culverts up to three feet in diameter. (Note – SBH – Segmented drains) and the same bricks are exhibited as lining for wells; and also the well-known, hollow bricks of which he is the inventor.

19/01/1948 – Aberdeen Press and Journal – Executry notice. All persons having claims against the Estate of the late James Green, brickworks foreman, who resided Newark, Tipper, Ellon are requested to lodge same with the subscribers within ten days from this date. A. J. Raeburn & Co, Solicitors. Ellon. Agents for deceased’s executrix

Below – 20/04/1971 – Aberdeen Press and Journal – Cruden Bay Brick and Tile Co Ltd incorporating Sutherland Bricks Ltd, Brora. Stockists of spigot and faucet pipes and general building materials. Works at Cruden Bay, Aberdeenshire and Brora, Sutherland and Tipperty Ellon and Aberdeen Depot, 17 Back Milton Road, Aberdeen.

********************************

Below – The Scottish Industrial Archaeology Survey published a report in 1985 entitled ” A survey of Scottish brickmarks”. During the compilation of this report in which the survey officers visited working and derelict brickworks sites, many items of interest were donated or found. Many of these items were thereafter donated to the National Museum of Scotland. The item below is one of these items. A red clay roof tile stamped ‘Symons Bros, Fairfield, NSW”.

t was recovered at the Tipperty Tile Works, Logie Buchan, Aberdeenshire, Scotland in c.1985.

I assume it was manufactured in Australia and found its way to Scotland. The Symons Brothers of Fairfield, NSW, Australia certainly appear to have been manufacturing such items.

Why it ended up at a tileworks in Scotland is anyone’s guess as the Scottish tileworks would have been making such items too and would have had no need to buy roof tiles from elsewhere. Could it have been taken to compare products? Could it have actually been made in Scotland for the Symons Brothers in order that they could compare products but never sent?

Is this a recognised Symons stamp?

Any ideas?

.

21/06/1951 – The Biz – An obituary. Mr Rudolph Symons. Co-founder of the widely-known Symons Bros, Tileworks, Mr Rudolph Symons, passed away on Monday, June 11, at the mature age of 81 years. The late Mr Symons, who had resided with his nephew, Mr Cliff Green, of North Street Fairfield for the past 10 years, was born in Somerset, England, and followed in the footsteps of his ancestors in the manufacture of tiles. With his brother, Orlando G. Symons, the late Mr Rudolph Symons came to Australia about 56 years ago, and after a thorough survey, selected the present location of Symons Bros Tileworks being the best site procurable for tile making. He devoted most of his time to this roofing product, and in so doing made the Symons Bros tile a by-word in the industry, and the high, standard which is oft quoted by builders. Mr and Mrs Symons resided in a lovely old home at the corner of Station and Marlborough Streets, Fairfield, for many years, and their gardens and lawns were a showpiece of the district. The tileworks, Fairfield, are the oldest still in operation In N.S.W., and probably in Australia. Two sisters survive, one in England, and one in Auburn, Mrs Trenholme. The funeral took place on Thursday afternoon, June 14, at 3.15 p.m., leaving the funeral parlours of Metcalfe and Morris, Parramatta, for Rookwood Crematorium.

(Note – SBH – The above article certainly provides us with a Symons link for England and Australia but still no connection with Tipperty, Scotland).