Dundyvan Brickworks, Coatbridge, North Lanarkshire.

Eglinton Chemical Company Limited, Dundyvan, Coatbridge.

The Eglinton Silica Brick Company Limited, Dundyvan, Coatbridge.

Eglinton Magnesite Brickworks, Dundyvan, Coatbridge.

(Note – SBH – I am not certain, but I believe the Dundyvan Brickworks (Fireclay Works?) were situated within the Dundyvan Ironworks complex and later these brickworks were taken over by the Eglinton Silica Brick Company. Again I am uncertain if both works occupied the exact same location or different sites within the ironworks complex. Likewise, the Eglinton Chemical Co also operated from Dundyvan and were early manufacturers of silica bricks. A branch of this company, also operating from this general area was the Eglinton Silica Brick Co Ltd).

Below – 1856 – 1860 – Eglinton Chemical Works and Dundyvan Brickworks? Coatbridge.

1858 – Mineral Statistics of the United Kingdom of Great Britain and Ireland for 1858 – Dundyvan, clay of coal measures. Name of freeholder – D. C. Buchanan Esq. Manufacturer – Trustees of the late J. Wilson. Manufacture – stopping clay for blast furnaces. Estimated 1000 tons annually.

Below – 1858 – The Dunyvan Ironworks site. It details several structures marked as kilns and also perhaps a structure(s) detailed as Refractory Furnaces but it is difficult to read).

1876 – Eglinton Silica Brick Company Limited was established.

1877 – SS Eglinton – A Coaster for general cargo, built in 1877 for the Eglinton Chemical Company. Wrecked 23/04/1882.

1878 – Eglinton Chemical Co. 31 St. Vincent Place. W. J. A. Donald, secretary.

31/08/1885 – Glasgow Herald – The mining exhibition, Glasgow … The Eglinton Chemical Company exhibits silica bricks …

1888 – The Eglinton Chemical Company, Limited, 27, St. Vincent Place, Glasgow. This has proved one of the most successful, as it is one of the most enterprising, concerns in the Scottish chemical trade. Founded about seventeen years ago to engage in the bichrome industry, it has developed in various directions since; but these directions have been in the line of making the most of its natural resources, and utilising its by-products and waste materials.

While its head offices are situated in St. Vincent Place, its chief works, with which connection is maintained by telephone, are located at Irvine, about thirty miles distant, which was, we believe, originally selected as a fitting site owing to the low agricultural value of the ground there and its proximity to a good harbour and the mainline of the Glasgow and South Western Railway. These works have been enlarged from time to time, and now constitute an extensive manufacturing centre devoted to the production on a considerable scale of bichromate of potash, patent bichromate of soda, and bleaching powder, with such other chemicals as are incidental to the production of these — such as sulphuric and muriatic acids and sulphates of potash and soda.

The ground covered by the works and used for the deposit of waste extends to about one hundred acres. We understand that arrangements have been made to include in the products of the establishment such other chrome salts as may be wanted by consumers, such as chromic acid, chromate and bichromate of ammonia, lime, &c., &c. In addition to the Irvine business, the Company now control five other important works, forming, as has been already indicated, the development to some extent and the result in a large measure of constant research during the management of the general business since its origination.

The first acquisition consisted in the Glenarm limestone field, with its large quarries all along the coast of the county of Antrim, from Lame northwards for about fifty miles to Ballintoy, served by the harbour of Glenarm, about seven acres in extent, the absolute property of the Company, and another at Ballintoy held under lease. In this business, they have three steamers of their own employed (in addition to steamers and sailers chartered from time to time), viz. Eglinton, Glenlut, and Glenarm — the latter the crack steamer of its size for carrying capacity, speed and equipment, in the coasting service. The exports consist of limestone and whiting, of which the Company are the largest shippers from Ireland, with lime shells and paving setts, the latter being made from a hard rock found adjacent to their limestone quarries; and Iron bauxite — now so largely used all over the world in the manufacture of alum, and which they were the first, through their managers, to discover in Ireland and to supply for this purpose. It has been found quite practicable, we understand, to ship as much as four thousand tons per week from these harbours, steamers being loaded there at the rate of one hundred tons per hour. The limestone is of very fine quality, containing about 98 per cent, of carbonate, while the bauxite, when deprived of its water of combination, analyses up to 70 per cent, of aluma and from 1 to 2 per cent, of iron.

The next manufactory in point of importance is their brickworks at Dundyvan, Coatbridge, in the very centre of the Scotch steel trade, where the flints obtained embedded in limestone at their Irish quarries, and bauxite brought from the same quarter, together with chrome ore such as is used at their Irvine works, are made into silica under processes patented by their manager, bauxite and chrome ore bricks respectively for lining Siemen’s, Martin’s steel furnaces, copper and gas furnaces, Bessemer’s converters, and for other metallurgical purposes. The flint bricks have already been largely adopted by the steelmakers to the exclusion of the Welsh Dinas bricks, which previously held the chief position in the estimation of the trade.

27/03/1888 – Ayr Advertiser – Glasgow Exhibition – Exhibits from Ayrshire – The Eglinton Chemical Company Limited, Irvine will exhibit various chromates, bichromate salts, and other productions of their chemical works; productions of their brickworks, consisting chiefly of silica bricks for lining steel smelting furnaces and chrome bricks for lining steel smelting furnaces and Bessemer converters …

30/05/1888 – Glasgow Herald – Glasgow International Exhibition – The Eglinton Chemical Company Limited show a number of novel forms of bricks in a neat showcase. The silica bricks shown are made from pure flint found embedded in limestone in their quarries in Ireland. These bricks are now largely used where the Welsh bricks were used before and are sent in considerable quantities to the North of England, Italy, Sweden and other places abroad. A brick made from a rich chrome ore, and a bauxite obtained from the mines in County Antrim, both patented by Mr Donald, manager of the company, are also shown, the former being suitable for resisting greater heats than the silica bricks and the latter being intended for blocks of steel furnaces and any other use where the bricks are exposed to the possibility of contact with metals. These bricks were first shown at the Mining Exhibition and have since been shown at the Edinburgh Exhibition, medals of merit having been granted on both occasions.

1889 – Eglinton Silica Brick Company Limited, Dundyvan, Coatbridge owned by the Eglinton Chemical Company in 1889 and managed by J. A. MacDonald. It was one of the few Scottish brickworks to specialise in making silica bricks. In the 1914 – 1918 war when the supply of Austrian magnesite was cut off, the brickworks turned to burning Greek and Manchurian raw magnesite. It was known as the Eglinton Magnesite Brick Company in 1928. Source Kenneth W Sanderson.

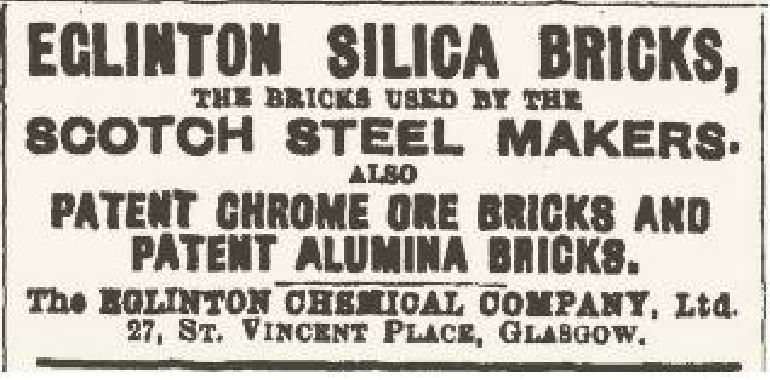

Below – 25/01/1889 – Advert appeared in the Iron and Steel. Eglinton Silica bricks – Scotch Steel Makers – patent chrome ore bricks and patent alumina bricks – The Eglinton Chemical Company, 27 St Vincent Street, Glasgow

30/04/1889 – Dundee Courier – Scottish Exhibitors at the Paris Exhibition – The Eglinton Chemical Company Limited – chemicals and silica bricks for steel smelting furnaces.

1890 – 1891 – Eglinton Chemical Company Ltd. Silicate Bricks, Eglinton Brickworks, Dundyvan. Coatbridge. Office 20 St Vincent Place, Glasgow. W J A Donald Agent.

Below – 1891 – Edinburgh Gazette – Eglinton Chemical Company Ltd.

1892 – SS Eglinton – A Coaster for general cargo built in 1892 for the Eglinton Chemical Company – 22/01/1902 sailed from Sunderland for Inverness with coal, posted missing. Wreck site details.

1893 – 1896 – Eglinton Silicate Brickworks. Works – Coatbridge. Eglinton Chemical Co Limited.

19/10/1895 – Airdrie and Coatbridge Advertiser – Eglinton Silica Brick Company Limited. The object for which this company has been established is to acquire from Wm. J. A. Donald, of 70 Great Clyde Street, Glasgow, the ground and buildings at Dundyvan Road, Coatbridge, presently occupied by the Eglinton Chemical Company Limited, as brickworks, with the machinery, plant, and stock, and goodwill and book debts of the business. Capital £3500, divided into 3500 shares of £1 each. The first subscribers are—Wm. J. A. Donald, chemical manufacturer, 70 Great Clyde Street, Glasgow, one share; Charles E. S. Macgregor, assistant manager, Dundyvan Brickworks. Coatbridge, one share; Wm. Donald, clerk, 70 Great Clyde Street, Glasgow, one share; Robert Donald, student, 40 Lily Bank Gardens, Glasgow. one share; Charles McArthur, writer, 149 West George Street. Glasgow, one share; James McFarlane, clerk, 70 Great Clyde Street, Glasgow, one share; and James Murdoch, salesman, 70 Great Clyde Street, Glasgow, one share. The registered office is situated at 70 Great Clyde Street, Glasgow. Messrs Macbride, Davidson, McArthur, and Stevens, 149 West George Street, Glasgow, are the solicitors for the company.

Below – 1897 – Eglinton Silica Brickworks, Dundyvan.

24/11/1897 – Glasgow Herald – A most exciting scene occurred in the vicinity of the Silica Brickworks, Coatbridge, yesterday morning. A number of young women are employed in different capacities in the works, and within the past few days, considerable dissatisfaction has been felt by them because the manager had considered it necessary to place them on reduced time and to make a proportionate deduction from their wages. The intimation that it was intended to depart from the former practice led to loud and ominous mutterings which culminated in the announcement that it was intended to enter on a strike. Yesterday morning an entirely new staff of female workers was brought into the works and so cleverly had the arrangements been carried out that it was some time before it became generally known that anything definite had been done. In the course of the morning, the strikers began to gather in the vicinity of the works and as the breakfast hour approached they besieged the gate. The new workers, on endeavouring to leave the works, were greeted with wild shouts. Howling and shouting was followed by wild gesticulations and threatenings, and stones were thrown freely in all directions. No arrests were made though it is anticipated that proceedings may be instituted against some of the leaders of the strike for intimidation and assault.

27/11/1897 – The Scotsman – Settlement of Coatbridge brickworks dispute. It is stated that the strike at the Coatbridge Silica Brickworks has come to a somewhat sensational termination. On Wednesday the workers sent a deputation to Glasgow to meet the directors of the company to whom they stated their grievances. On Thursday a meeting was held at the works and the enquiry instituted is said to have resulted in all the strikers without exception being reinstated.

02/12/1897 – Glasgow Herald – Brickworks – Foreman wanted, experienced thoroughly steady and capable man to manage Silica Brickworks near Glasgow. Wages for a first-class man, 50s per week with engagement – apply by letter only, stating experience to the Eglinton Silica Brick Company Limited, 70 Great Clyde Street.

02/12/1897 – Glasgow Herald – Brick setter wanted. A first-class steady man experienced in brick setting. Apply personally to the Eglinton Silica Brick Company Limited, 70 Great Clyde Street.

14/12/1897 – Glasgow Herald – Brickworks manager wanted. Smart, reliable, experienced brickworks manager for silica brickworks near Glasgow. Salary to begin £150, £200 per annum according to experience and qualifications. Apply in writing only, stating experience to the Eglinton Silica Brick Co Ltd 70 Great Clyde Street.

25/03/1899 – Airdrie and Coatbridge Advertiser – Wanted, silica brick kiln setter. Apply Eglinton Silica Brick Co, Coatbridge.

01/07/1899 – Airdrie and Coatbridge Advertiser – Wanted, silica brick maker, also a kiln setter. Apply Eglinton Silica Brick Co, Coatbridge.

04/11/1899 – Airdrie and Coatbridge Advertiser – Wanted, brick kiln setter. Apply Eglinton Silica Brick Co, Coatbridge.

Below – 09/12/1899 – Eglinton Chemical Company – Front page of a supervision order for winding up the company.

13/12/1899 – Glasgow Herald – Court of Session. The Eglinton Chemical Company Limited (in liquidation) and Patrick Graham, the liquidator thereof have lodged answers to the petition of W J A Donald. They contain the following … In the corrected balance sheet it appeared that the petitioner was a debtor of the company to the extent of £4351 15s 11d and that two companies carried on by him, the Firhill Lime and Whiting Company (Limited) and the Eglinton Silica Brick Company (Limited), of which companies he was practically the sole owner, were debtors to the respondents to the extent of £876 11s 2d …

23/01/1900 – Edinburgh Evening News – A litigious Glasgow Company – In the court of session today, Lord Kincairney closed the record in 3 actions at the instance of the Eglinton Chemical Company Limited. 212 George Street, Glasgow … the 3rd action is against the Eglinton Silica Brick Company Limited, 8 Firhill Road, Glasgow and concludes payment of £921 with interest. It is stated by the pursuers that they have for years past supplied the defenders with calcined flints and cleaning waggons and that the sum sued for is the balance still due to account …

The Company’s other works are of less importance, their Firhill Works in Glasgow forming an auxiliary chiefly to the Glenarm Whiting Works, but including in their operations the grinding of flint and Cornish stone for use in the Potteries, and their tannery in Glebe Street, also in the city, being devoted to the working out of a process of tanning leather by means of bichromates, the Company’s staple article of production, and which is expected to become of considerable importance as the supply of bark for tanning purposes is becoming less easy to be obtained.

Altogether, the Eglinton Company employ about one thousand men, and they are represented at home and abroad by agents of first-rate standing, the following being amongst the number, viz.: London — Mr. W. A. Bowditch, 43, Mincing Lane; Liverpool — Messrs. John Haddock & Co., Exchange Buildings; Lancashire — Messrs. John Bayley & Co., Manchester; Yorkshire — W. P. England & Co., Huddersfield; France and Belgium — Gray, Laurier & Co., 17, Philpot Lane, London; Italy, Spain, and Portugal — Scott Bros., Newcastle-on-Tyne; Germany and rest of Europe — Borries, Craig & Co., Newcastle-on-Tyne; United States of America — J. L. and D. Biker, New York; Canada — W. T. Benson & Co., Montreal.

We need hardly add that the directors are manufacturers and merchants of great experience as well as large capitalists, as may be judged by the enterprise and success which have characterised the career of the Company. The general manager and secretary is W. J. A. Donald, who has been associated with the Company as secretary and manager since its first inception.

Feb 1900 – British Clay Worker – New Companies. The Eglinton Limestone Company Limited to carry on the business of manufacturers, merchants, miners, quarrymasters, brick manufacturers etc at Glenarm in the County of Antrim, Ireland and in Glasgow. Capital £12,000 in £1 shares. Registered Office, 212 West George Street, Glasgow.

21/03/1901 – The Scotsman – W J A Donald v Eglinton Chemical Company &c. Four actions in which the parties were William John Alexander Donald, merchant and manufacturer, Firhill Road, Glasgow; The Eglinton Chemical Company and liquidator; The Eglinton Silica Brick Company Limited and the Firhill Lime and Whiting Company Limited have been settled. The action had reference to transactions for the sale of bauxite and other products of the Eglinton Chemical Company. Disputes arose as to the state of accounting between the parties but these have been settled ex-judicially and the actions were taken out of court by a joint minute …

1903 – Eglinton (The) Silica Brick Co. Limited (Silicate bricks) – Eglinton Brickworks, Dundyvan; office, South Exchange Court, Glasgow.

1907 – Eglinton Silica Brick Company Limited, 70 Firhill Road, Glasgow.

11/09/1907 – Coatbridge Express – Leaving work without notice. Yesterday, in the Sheriff Court—before Sheriff Glegg—Bernard Mullen, labourer, Buchanan Street, Coatbridge, sued the Eglinton Silica Brick, Co, Ltd., Dundyvan Brickworks, Coatbridge for as wages due to him for three days and two hours. The defence was that the pursuer deserted his employment without notice and was not entitled to recover the sum sued for. Mr J. J Bannen, Coatbridge, appeared for the pursuer, and Mr James Bell, Airdrie, for the defenders. Proof was led to show that the rules of the works, which were posted up, required a week’s notice on either side of termination of employment. The defender said he was illiterate and could not read the notice, and that he was never told. The Sheriff absolved the defenders with expenses.

Below – 1910 – Eglinton Silica Brickworks, Dundyvan.

1910 – 1911 – Eglinton (The) Silica Brick Co. Limited. Manufacturers of Magnesite bricks and cement for basic furnace linings.Works Dundyvan, Coatbridge. Registered Office – William J. A Donald, 60 Firhill Road.

1910 – 1911 – Eglinton (The) Silica Brick Co. Limited. Manufacturers of Silica, Bauxite, Chrome and Magnesite bricks and cements for acid and basic furnace linings. Registered Office – William J. A Donald, 60 Firhill Road.

1911 – 12 – William J. A Donald, Manufacturer, 60 Firhill Road (Of the Eglinton Silica Brick Co, Ld., and the Firhill Lime and Whiting Co., Ld; works, Coatbridge and Glasgow); res., Coltswood, Coatbridge.

Below – 1912 – Advert for the Eglinton Silica Brick Company Ltd, Glasgow.

1914 – The Hurll, Garnqueen Works was closed at the start of the 1914 war due to a shortage of labour. The steel industry was desperately short of calcined magnesite for fettling the furnaces, as this magnesite was all imported from Austria, so raw magnesite was imported from as far away as Manchuria and calcined by the Eglinton Silica Brick Company of Coatbridge. To supplement their production they took over the Garnqueen Works to make more calcined magnesite or periclase. After the war, the Garnqueen Works was used to make briquettes from iron ore fines for the Tharsis Company thus enabling them to be used for the blast furnace feed …

23/01/1915 – Coatbridge Leader – Brickworks manager killed. Early on Monday morning, a sad fatality occurred on the branch line of the North British Railway which passes the Eglinton Silica Brick Works, Dundyvan. Following his usual practice, Mr William J. A. Donald, managing director, looked in at the works prior to proceeding to the head office of the Company in Glasgow. His visit of inspection being completed, he was leaving to travel with the seven o’clock train to Glasgow, when in crossing the branch line at the works he was knocked down by a shunting engine and run over. His injuries were of a shocking nature, the head and an arm being severed from the body. No one saw the accident happen, and the first that was known of it was when the deceased’s lifeless body was found lying at the side of the line.

23/01/1915 – Airdrie and Coatbridge Advertiser – The late Mr W. J. A. Donald. Inventor and trade pioneer. The funeral took place to the Necropolis, Glasgow, on Thursday of Mr William J. A.Donald, Coltswood House, Coatbridge, who was accidentally killed at his works in Coatbridge on Monday morning last. Mr Donald had keen visiting the works before going to his Glasgow office and as the morning was foggy and dark he failed to notice the approach of a train of waggons which was being shunted to a siding at the works. He was knocked down and killed instantaneously. Mr Donald was for many years closely associated with the biochrome industry. Possessed of such versatility and enterprise, he became a pioneer in several branches of the trade. He was the inventor and original patentee of the process for making chrome bricks, now indispensable to steel manufacturers. He was also the first maker of chrome tanned leather in Great Britain, an industry which has since reached great dimensions in many countries. In 1893 Mr Donald contributed a paper to the Glasgow Philosophical Society on the subject of chrome tanning. The many and varied products of his manufacture have gained the highest awards at the great international exhibitions, including those of Paris, Frankfurt, London, Glasgow, and Edinburgh. Mr Donald was of a genial and kindly disposition and was greatly esteemed by a wide circle of business and personal friends.

27/02/1915 – Airdrie and Coatbridge Advertiser – Whifflet railway accident. The first inquiry was into the circumstances attending the death of Wm. John Alexander Donald, brick manufacturer, Coltswood House, Coatbridge. George M. White, a cab driver, Academy Street, stated that he was in the employment of the deceased, who was managing director of the Eglinton Silica Brick Works and drove him from Coltswood House to the works at 7.15 a.m. on 18th January. He landed him at the end of Stobcross Street between 7.30 and 7.35. It was a specially dark and stormy morning. About 10 minutes later be learned that Mr Donald had been run down by a railway waggon and killed. Evidence by Allan, one of the employees in the office, stated that the ceased was in the habit of coming and giving him instructions for the day’s work. One of the railway employees had that morning been asked to shunt in two waggons of magnesia into the works and 35 minutes later they were being pushed in, in front of an engine. It was dark and very gusty at the time. A man was walking in front of the waggons with a lamp in his hand. The waggons moved in at the gate leading to No. 3 lye which comes off the Souterhouse branch of the North British Railway and runs along the works. A few minutes later he heard that Mr Donald had been knocked down by the waggon which he had not seen in the darkness. Corroborative evidence was led. A girl employed as a brick worker spoke to noticing that someone had been run down. The Sheriff—How did you get into the works that morning?—Through the top gate at the level crowing. That is the main entrance to the work off the railway. The jury returned a formal verdict.

27/02/1915 – Coatbridge Leader – A court case surrounding people trespassing on the railway line by taking a shortcut to get to their work at the Eglinton Silica Brickworks. It was highlighted that there was no direct route for workers on the other side of the railway line from the Dundyvan Brickworks to get to their work other than crossing the tracks.

15/05/1915 – Airdrie & Coatbridge Advertiser – Office boy wanted. A good writer and calculator. Apply on Monday between 9 and 10.30 a.m. The Eglinton Silica Brick Co Ltd, Dundyvan, Coatbridge.

15/02/1916 – The Scotsman – Wanted to lease for government work for the period of war, fireclay brickworks capable of production 15-20 thousand bricks weekly. With offers, particulars of kilns are requested. The Eglinton Silica Brick Co Ltd, 60 Firhill Road, Glasgow.

21/03/1916 – Daily Record – Men wanted immediately for temporary employment during this week discharging magnesite from wagons on to the ground; 6d per ton will be paid each man as soon as wagons are emptied … The Eglinton Silica Brick Co Ltd., Atlas Brickworks, Armadale.

Men wanted immediately for temporary employment during this week discharging magnesite from wagons on to the ground; 6d per ton will be paid each man as soon as wagons are emptied … The Eglinton Silica Brick Co Ltd., Shawsrigg Brickworks, Larkhall.

Men wanted immediately for temporary employment during this week discharging magnesite from wagons on to the ground; 6d per ton will be paid each man as soon as wagons are emptied … The Eglinton Silica Brick Co Ltd., Garnqueen Brickworks, Glenboig.

03/06/1916 – Airdrie & Coatbridge Advertiser – Three night foremen wanted. Apply to the general manager, Eglinton Silica Brick Co Ltd, Dundyvan Brickworks, Coatbridge.

10/06/1916 – Hamilton Advertiser – Wanted – Joiner for our Cleghorn Works – Apply The Eglinton Silica Brick Co Ltd, 45 Renfield Street, Glasgow on Monday. Also wanted – A first-class mechanic for our works at Cleghorn.

29/06/1916 – Hamilton Advertiser – Stonebreaker (experienced) wanted. Good wages, a local man preferred. Apply personally to The Eglinton Silica Brick Co Ltd – Terra Cotta Works, Cleghorn.

15/07/1916 – Coatbridge Leader – The strike at silica brickworks. Coatbridge work girls before the munitions tribunal. A general munitions tribunal sat in the County Buildings, Glasgow, last Saturday to consider a charge brought by the Silica Brick Company (Limited) against women and girls in their employment at Coathridge, and who were accused of taking part in the recent, strike there. Sheriff Fyfe was chairman, and Miss Young and Robert Baird were the assessors.

Mr William Duncan, managing director of the company, stated that they were the only manufacturers of magnesite bricks in Scotland and as those were urgently required for lining furnaces in the steelworks of two of the Allied countries, their entire output was made available for the Ministry of Munitions. The establishment was not controlled. A machine for making the bricks, installed about a year ago, was recently substituted for the hand labour of workmen. The Ministry of Munitions had intimated that they would not be satisfied until their output had reached the top level of this machine. They accordingly asked the women to work longer hours, assuring them it would be lighter, and that no change in the rates of wages would be made. The women asked for increased wages in respect of three additional hours’ work, and their request was agreed to. Subsequently, however, believing that several of their number had been dispensed with, the respondents refused to resume work on the grounds that the agreement had not been kept by the firm. The works manager, in his evidence, denied that these girls had been dispensed with; they were merely suspended.

An agent for the employers said they had no desire to be hard on the girls, and suggested they should give an undertaking to return to work and obey the new conditions.

Mr Owen Coyle, who represented the respondents, agreed to this proposal, provided the status quo prevailed.

The Sheriff – What business is it of theirs as to the number of people employed here?

Mr Coyle agreed that it was the right of the firm to staff their works, but contended there was a duty incumbent on the employers to intimate altered conditions. He explained that the respondents were not members of any trade organisation.

The Sheriff – They are not to dictate to the management. Any reasonable representation will, I feel, receive consideration from the management, but that is very different from taking up the attitude that they are bound to be consulted.

Two of the respondents said they realised now that they should have continued work; they were ignorant of the provisions of the Act. The firm’s agent stated that he was informed all the workers had been retained.

The Sheriff, in admonishing the respondents, said surely they realised that any, thing which hampered the production of anything necessary for the prosecution of the war was a very grave offence, chiefly against their own country. He could not too strongly impress upon them that any stoppage of work for any time during the war was taking part in a strike and punishable by a penalty of £5 for every day they were out on strike. But that prosecution had, he thought, served a good purpose as it had cleared the air of certain opinions the respondents seemed to have entertained which would be subversive of all discipline in the conduct of industrial work. Respondents must dismiss from their minds that they had to be consulted, or have a say, in the direction of these works in which they were employed. If their conditions were not agreeable they had their remedy and would have them considered.

Mr William Donald, managing director of the Eglinton Silica Brick Company, Ltd., points out that he thinks it right to state that, as they were naturally desirous of being associated in their manufactures with the munitions requirements of Great Britain, their productions were required not only for the steelworks and copper works of all the Allied countries but also for those of our own country and the British Colonies. In taking action against their workers they did so in what they considered to be the general interest, so that they and many other workers should know that strikes are illegal during the period of the war., whether the workers are men or women. and whether the employer’s works are controlled establishments in the terms of the Act or not.

20/01/1917 – Coatbridge Leader – At the Dean of Guild Court on Thursday afternoon a plan of a brick engineer repair shop which the Eglinton Silica Brick Company (Limited) propose to erect within their works at Stobcross Street, Coatbridge was passed. The dimensions of the building, as shown on the plan, will be 61 feet by 26 feet.

03/02/1917 – Airdrie and Coatbridge Advertiser. Coatbridge military tribunal. All-day sitting. A single managed 24 employed by the Silica Brick Company asked for exemption on the grounds that he was the sole support of his widowed mother. The case was continued for medical examination.

28/02/1917 – Coatbridge Express – At a meeting of the Middle Ward Water Committee on 12th ult.. a question arose as to the water supply for Garnqueen Brickworks, Glenboig. The clerk submitted a letter, of date 5th January, which he had received from the Clerk to the Lower Ward District Committee stating that a communication from the Harland Engineering Company on behalf of the Eglinton Silica Brick Company had been submitted to the last meeting of Cadder Water Committee, requesting consent to take the water for the brickworks from the Airdrie and Coatbridge Trust, which also supplies the Gartliston Works, the length of piping required being thus shortened by 400 yards and that the Cadder Water Committee having regard to the circumstances had agreed not to object to this proposal. The Lower Ward Clerk also stated that he had just received a further letter the Harland Company stating that the matter which, when the application was first made, had been stated to be one of urgency, was now in abeyance. The committee agreed that in the circumstances, no action was called for on their part. The minute was approved.

24/03/1917 – Airdrie and Coatbridge Advertiser – Failing to answer the telephone. Yesterday, before Sheriff Lee, the manager in charge of the industrial establishment in Stobcross Street, Coatbridge, of the Eglinton Silica Brick Coy., Ltd., which company was granted a conditional exemption as regards said establishment from the requirements of the Lights (Scotland) Order by Wm. McDonald, Chief Constable, Coatbridge, between 2.22 and 2.29 a.m. of 12th March 1917, being more than half an hour before sunrise, he failed to accept through the telephone at said establishment within 15 seconds, of its despatch, a test call which was sent at that time by the night operator at the Telephone Exchange, Coathridge, contrary to the Defence of the Realm Consolidation Regulations. He pleaded guilty. Mr R Denholm, solicitor, said the management had made arrangements for attention to the ‘phone being carried out, and they regretted that in this instance it had not been done. The Fiscal (Mr Lindsay) said the Company had been warned several times previously. The Sheriff pointed out that if attention was not given to the telephone as required by this Order, the exemption referred to might be withdrawn. He imposed the same penalty as in the first case of the kind a fortnight ago, namely, £5, but he was bound to say that if there were repetitions of this neglect he would have to impose a much more serious penalty.

18/08/1917 – Coatbridge Leader – Mr J. A. Milligan, works clerk, Eglinton Silica Brick Co., Ltd., has been presented with a pocketbook and a wristlet watch with a luminous dial as a token of esteem from the workers, on the occasion of his leaving to join the colours. The presentation, which took place within the works on Monday night, was made by Mr B. McNeil, the oldest employee.

18/08/1917 – Coatbridge Leader – Brick workers wages increased. Professor Irvine has sent to Baillie Climie, Workers Union, the following award dealing with the men employed at the Dundyvan and Garnqueen Works of the Eglinton Silica Brick Company Ltd. ” That as from 19th April 1917, the wages of male workers of 18 years of age and over in the employ of the firm shall be increased by 4s per week, and that the wages of boys and youths under years of age in the employ of the firm shall be increased by 2s per week. The amounts hereby awarded are to be regarded as war advances, intended to assist in meeting the increased cost of living and are to be recognised as due to and dependent on the existence of the abnormal conditions now prevailing in consequence of the war; that the advance of 2s per week offered by the firm to the workmen on or after 19th April, and accepted by certain of the workmen, shall merge in the advance hereby awarded; and that the claim for double-time payment for Sunday work has not been established.”

12/12/1917 – Daily Record – Bricklayers wanted at Garnqueen Brickworks, Glenboig. Class A work – Eglinton Silica Brick Company.

Six brickworkers wanted at Garnqueen Brickworks, Glenboig. Class A work – Eglinton Silica Brick Company.

02/03/1918 – Coatbridge Leader – William Currie, the nine-year-old son of William Currie, ironworker, 9 Coatbank Street, was accidentally drowned last Saturday afternoon by falling into the Luggie Burn, near the south side of the Eglinton Silica Brick Works, off Stobcross Street, belonging to the Eglinton Silica Brick Company, Limited. The boy had taken off one of his boots for the purpose of going into the burn to get a football which had been accidentally kicked in. After he had recovered it he was sitting on the bank putting on his boot, when it slipped from his hand into the water. While endeavouring to regain possession of the boot he overbalanced and fell into the water and the force of the current carried him through the culvert which passes under the Caledonian Railway. The poor boy was thus drowned before assistance could be got. The body was taken from the water shortly afterwards and artificial respiration was applied by Constable George Jackson for about 20 minutes, but his efforts were of no avail.

13/04/1918 – Daily Record – Kiln Burner wanted – Apply The Eglinton Silica Brick Co Ltd, Dundyvan Brickworks, Coatbridge.

19/12/1918 – Daily Record – Brickworkers wanted – Eglinton Magnesite Brickworks, Dundyvan, Coatbridge (Same as Eglinton Silica Brickworks?).

01/03/1919 – Airdrie and Coatbridge Advertiser – Wanted. Man to fire boiler and attend engine. Apply the Eglinton Silica Brick Co Ltd, Dundyvan Brickworks, Coatbridge.

22/03/1919 – Coatbridge Leader – The Eglinton Silica Brick Company, 15 Renfield Street, Glasgow were likewise granted authority to erect an engine room and wet mill at their Stobcross Works, Coatbridge.

19/04/1919 – The Scotsman – Important sale of brickmaking plant and machinery at Garnqueen Brickworks, Glenboig on Tuesday 6th May at 12 o’clock. Shirlaw, Allan and Co, auctioneers, Hamilton have received instruction from Messrs Eglinton Silica Brick Co Ltd, 45 Renfield Street, Glasgow to sell by auction as above. Particulars afterwards. Catalogues from auctioneers, Hamilton. April 1919.

Below – 29/04/1919 – Sheffield Daily Telegraph – Eglinton Silica Brick Co Ltd for sale.

Below – 04/06/1919 – Kirkintilloch – Water supply issues at the Eglinton Silica Brickworks, Glenboig.

1920 – Special report on the mineral resources of Great Britain – The Eglinton Silica Brick Co., Ltd. 45, Renfield Street, Glasgow. The silica-brick trade in Scotland was started by the Eglinton Chemical Co., of which the present company was originally a branch, about the year 1876, for the supply of silica bricks to Scottish Steel Works. The raw material at first employed was flint from County Antrim, Ireland. Later, chalk flints were imported from the Thames and, to a certain extent, from the northern shores of France. The Thames flints could at one time be bought at 5s. to 6s. per ton c.i.f. Grangemouth. These flints were calcined in shaft kilns, and each kind had different characteristics; the French flints, while purer chemically, were low in fusion point. The bonding material was highly plastic clay obtained from South Wales. The bricks were moulded by hand machines, which, until recently, were exclusively used in this country for moulding silica bricks; these have now been superseded by power presses, which are doing just as satisfactory work as that done in the past by manual labour. After being dried, silica bricks were burned in Beehive kilns, at a temperature of about 1400° C. These flint bricks contained about 93 per cent, silica, the balance being alumina, lime and iron. They were chiefly used in the chequers of steel furnaces, where they would stand better than the best English bricks. They were, however, used also in the crowns of steel furnaces in several works in Scotland, as well as in other parts. One great advantage of these bricks consisted in their less expansion than other silica bricks, and they were, therefore, better able to withstand variation of temperature without cracking. Also, they could be employed in furnaces for repairs during fettling, and for this purpose alone were in great demand. Until recently little enquiry had been made as to the ganisters used in Scotland, but, judging from the samples that have been hitherto submitted to us there is nothing in this country to compare with the English ganister. There are, however, considerable deposits of quartzite in the islands and west coast of Scotland which have been brought to our notice by the Geological Survey, and which, we believe, could be easily delivered at Glasgow at prices which should enable them to be used for refractory purposes. Quartzites are largely quarried in the United States for the raw materials of silica-brick manufacturers. Practical tests have been made of the samples submitted, and our opinion is that the deposit -Sample No. 2 (North side of Loch Leven, Ballachulish, 1 mile east of Callart Cottage), might be expected to give the quartzite best fitted for tile manufacture of silica-bricks. The Eglinton Silica Brick Company is at present (1916) entirely engaged in the manufacture of magnesite bricks from imported material. The above information and report on samples has been kindly supplied by Mr Wm. Donald, Manager of the Eglinton Silica Brick Co.

28/01/1920 – Coatbridge Express – Miraculous escape. About 11.45 am on Thursday, Frank O’Rourke, a roofer, residing at 3c8 Dundyvan Road, met with an accident while at work at the new shed at the southeast side of the Eglinton Silica Brick Works. His clothing was caught by a revolving shaft and the man himself whirled around the shaft. His left struck a steel beam that projects from the side of the building and he sustained a compound fracture of bones between the knee and the ankle. Fortunately, when his clothing gave way he fell to the ground otherwise the injuries might have been more serious. After being attended to by Dr Rennie, O’Rourke was removed to the Alexander Hospital.

20/03/1920 – Coatbridge Leader – Robert Muir, labourer, Sunnyside Road, adhered to a plea of not guilty on charges of breach of the peace and assault, said to have been committed at the Eglinton Silica Brick Company’s works on 9th March. For the prosecution, James Milligan, clerk, Hollandhurst, Gunny, stated that he was employed at the Silica Brick Company’s works, and the accused was also an employee. A mistake was made in the accused’s pay on 7th February, about which he called at the office. He asked if he would be paid back, and the witness replied that he would hear about it. The witness was dealing with the complaint and asked Muir to leave the office. Accused, however, cursed and swore, and struck him. Afterwards, the witness called the police and gave Muir in charge. He (witness) gave no provocation. Questioned by the accused, the witness said he asked him to bring his pay line. John Hendry, assistant manager, saw Muir strike the complainer and heard him cursing and swearing. Bailie Kellock found the charges proved, remarking that Muir had done wrong and must pay the penalty. He had no right to take the law into his own hands. The sentence was a fine of 20s or ten days in prison.

20/03/1920 – Airdrie and Coatbridge Advertiser – Wanted immediately, two bricklayers and two kiln burners. Apply to the works manager, The Eglinton Silica Brick Co Ltd, Dundyvan.

23/06/1920 – Coatbridge Express – History of Dundyvan Brickworks. The employees of the Eglington Silica Brick Company Limited at Dundyvan Brickworks had their annual trip to Lanark on 5th June and a goodly company enjoyed the outing in the ancient burgh. Mr Wm. Donald, general manager, was present and at the conclusion of dinner, he made interesting reference to the history of their works.

Many trades, he said, that put out enormous efforts for the country during the war have had to pause and look around now that the war is over but with us it is different. Our trade is to supply the requirements of the steel trade and if the steel trade is busy, we shall be busy. Our duty is to see that the steel trade is never short of supplies of magnesite bricks. Another of our duties is to see that they get plenty of ground magnesite. And, as soon as we can, we should make them some chrome bricks, but we can’t do that while we are busy on magnesite bricks. When we do all we can, we are doing our bit. That is why you are all so busy, and you can understand from what I have said that we could have plenty to do for a long time ahead.

If we do all we can to keep the quality up to our highest level we will always have plenty to do, and something to spare for others in the trade. It doesn’t do to be the only arm in the trade. I find the other members real good friends, we have an Association – The magnesite Brickmakers’ Association – so that in addition to being members of your own Societies you are members of the Magnesite Brickmakers’ Society. Some of you will know, and others I think will be interested to know, that in 1871 there was another war in Europe. At that time it was Germany and France who were fighting over Alsace and Lorraine. Some of you know Alsace, where Metz is, opposite and near to Verdun, and others will know Lorraine where Strasbourg is. Germany won and occupied Paris, and France had to pay up. Now the tables have been turned and France has got back the Alsace and Lorraine countries taken from her.

Now, it was soon after and as a result of that Franco-German war that the Eglinton business first began. Land was got at Irvine harbour, and works were started to make chemicals that were in great demand. Limestone wait required, and the best stone was in County Antrim, but they couldn’t get enough, so my father went over to Ireland and out the Glenarm Quarries from Lord Antrim, built a pier, and built two steamers and got his limestone that way. In that limestone there were beds of flints and flints were bad for the chemical works, so that had to be removed from the limestone and soon a good many thousand tons of flints accumulated and had either be made into something or cleared out of the way. Well, as a result of that war steel was required, and the Blochairn and Hallside Steel Works were erected in Scotland and required silica bricks. My father knew that silica bricks were being made from flints on the Thames or were trying to be made, and be decided to make them on the Clyde. At that time Roberts had a foundry in South Wales where he made castings for brick machines like what we used to use. After giving his price for brick machines he offered to supply mills and to build stoves and kilns and the result was that he gave up his business in South Wales and came to Scotland with Norman and Jim Hannaford, who is now the foreman at Braehead. Roberts became the first works manager at Dundyvan, and the stoves and kilns were built by Mr Jamieson, the builder, to the plans that Roberts brought with him from South Wales. So that Dundyvan with all these Welshmen began as a colony of South Wales -a little New South Wales. That was in 1889. There have been ups and downs since then. At first, the steel trade of the Clyde was most affected with the Clyde shipbuilding. When therefore shipbuilding was busy, so was Dundyvan. After Roberts, the manager was Norman, then McGregor, the man with the one arm and then Dan Fraser. Fraser left in 1909 and it was that summer I came among you and became the works manager for six years. You will remember that my father was run over in January 1915. At that time I was far from well and he was Dundyvan every day. One morning he came down early and came in at No. 3 gate. The pugmen didn’t see him, and the pug came round the corner too quickly and my poor father couldn’t get past quick enough. A good many of you will remember my father and his great interest in all stages of manufacture. Sometimes he was too particular. But he was an exceedingly goodhearted master, and to all who knew him well, a good friend. He had a wide circle of friends. His death made it necessary for me to take up the reins, and I wasn’t long in seeing that with the altered circumstances of the war, calcined magnesite couldn’t be got. We would have to take cargoes of raw magnesite. Now the Dundyvan kilns at that time weren’t enough to do much calcining, burning of slap bricks and burning of finished, and 1 made up my mind that, I had to get hold of another Works. At first, I thought of Braehead but I soon saw that wouldn’t do what would be required without more plant first being erected at Dundyvan, so I leased Garnqueen, with the expectation that the kilns there would at least be able to do the calcining. The cost of upkeep of these kilns working at our high temperatures was very great for the work they did and the quality of the calcined magnesite produced was not nearly so good as what can be done at Dundyvan.

Relating the work done during the war Mr Donald said – By October 1916, we had become the largest makers in this country. In October that year, the steel trade wasn’t getting enough. So all the makers were called to the Ministry of Munitions and we were all asked what we could do. I promised to increase our production by a quarter within three months and I was asked to do it When that was done I was told one day that bigger supplies would be required. Could I do anything more! Well, I knew myself from the orders I had to refuse that more was required and I had been making enquiries about other works I could get. So I promised to come back in a week and let them know what could be done. Well,, when I came to Scotland the likeliest works were Shawsrigg Works, Larkhall, and the calcining kilns at Armadale. So I went back in a week. I remember it was 4 o’clock, on a Saturday afternoon, and I offered to double the production within two months if that was wanted, provided I could get more magnesite and provided I got some Garnqueen man back from the Army. That was promised, so I went ahead, the kilns at Shawsrigg were muffle kilns. These muffles had to be cleared out. The old set of kilns had to have their crowns put right. A brick machine had to be got to Shawsrigg and erected there and the mills had to be thoroughly overhauled. The works had been idle for two years and workers had to be got. The railway siding plant had to be extended, and the water supply was bad. A new pump had to be got, and so on. Also, we had to get another machine for Garnqueen so that we could depend on one always being right. We had also to get a second lightning crusher. The first lightning crusher had been got from Braidwood. The first machine came from London. Another was got from Irvine. The next was got from Gloucester. The next was got from Hull. And the next was got from Dublin. It was only by getting them second hand from where they existed, in works that were closed down, that the machinery could be got in time. Well, that gave us Dundyvan, Garnqueen, Shawsrigg and Armadale. At Armadale, all we did was calcining. Calcining was also done at Shawsrigg and Garnqueen, as well as slap bricks, and the first burning came to Dundyvan to be made into finished bricks. Later there wasn’t ever then enough, and we had to take the works at Kilmarnock. There was great excitement at that time. I had already entered into a contract to supply the French Government with three-quarters of a million magnesite bricks. Now Italy had joined the Allies and a representative from their Ministry of Munitions in Rome called at 45 Renfield Street and asked what we could do. I said quite simply that there was no limit to what we could de if we had enough magnesite and enough works to make bricks. So they asked me to supply a quarter of a million, delivering 50,000 in May, June, July, August and September in 1916. As soon as the arrangements were completed I went ahead at Southhook Works near Kilmarnock. One of the ‘Clan’ Line arrived from India. The raw magnesite was sent straight down there. Soon we began to get it into slap bricks and got them out too. So the production game began on a bigger scale. Well, we were up to time with the increased production. A wire came from the Ministry saying they had a wire from Italy wanting the bricks. Where were they? So I replied they were still in the kiln but the kiln door was down the previous day and we could have them packed up and despatched that week. That was how the thing went on and by September 1916 we had delivered the 750,000 to France and the bricks to Italy as well. That having been done the question was – What next? Well, the usual course of business is to execute orders but during the war, more questions than that had to be taken into account. The Germans settled this particular question for us. They sank two steamers with magnesite and made such havoc with their submarines that it was decided to restrict all exports and only to import magnesite to meet the demands of the British works. These were going to be very great, and it would be difficult to get all the supplies of magnesite from Greece that would be required.

It was decided, therefore, that Southhook and Shawsrigg Works and the Armadale Kilns would be given up and we would work away with Dundyvan and Garnqueen. In the meantime, Dundyvan had grown. We had kilns 9, 10 and 11, and at Garnqueen we had built eight Newcastle kilns. At Dundyvan also we had added stoves 5 and 6. Since the Armistice, we had the sale at Garnqueen of all the spare machinery and since then we have gone ahead at Dundyvan setting our house in order. That is what the steelworks themselves had been doing, and soon their orders came along again. This time with increasing orders. I made up my mind that to get the extra plant to give the increased production I wouldn’t go back to fireclay works, but would erect the most modern plant at Dundyvan, taking the erections decided on in their order of most importance. When we get erected all that has been purchased we shall have the best magnesite works in Great Britain.

There is a good old saying that “All work and no play makes Jack a dull boy”. More than that, however, it makes him less able to concentrate his attention to matters that his competitors pay attention to. All workers in any branch of trade have competitors in that same branch of trade either in the adjoining street, town, county or country, and it is just as necessary for each worker to consider his work in that light as it is for the employers to think how they can compete with other employers by the introduction of better machinery and plant. Employers depend on the machinery and plant being worked with the highest skill, and with the greatest economy. It is up to the workers to back up the employers and each to compete, with the workers who are doing the same job in the towns or in other countries. On the other hand, it is up to the employer to consider whether they can assist the workers by giving good working conditions, light and fresh air, protection from bad weather and warmth whenever necessary. In country districts it is often necessary to provide travelling facilities and housing accommodation. In towns like Coatbridge, where the workers have the choosing of the town councillors just as much and even to a greater extent than the employers have, they can introduce in their towns good education, good lighting, good tramway travelling facilities, good drainage, and in these days of town planning they can also introduce good housing schemes. In works that are situated in burghs or towns, the employer has taxes to bear that lighten the burden of the residential inhabitants and the workers, so that the inhabitants are all the better able to have the best conditions of life in their midst. It is mainly in their works themselves that the employers have their responsibilities, but my opinion is that it would be good for all employers if they gave their workers ground for development in allotments so that their interests in many of the things they have learned in their youth in country districts can be sustained. It is my hope that soon will be able to provide our workers not only with improvements in the working conditions at Dundyvan in many respects but also that at no distant date we shall have a field, part of which can be used as a football field either by the younger workers themselves or by the children of the older workers and in part of which the workers will have allotments that they can cultivate for the growth of vegetables and flowers. You will see from the coloured print of the Veitsch Company’s Works and buildings that they have a bandstand and laid out gardens for their employees. If they had not deployed their works first they would not have gone in for such wonderfully good developments in these directions. But their enterpriser before the war was really wonderful, and their spirit I hope to develop at our works in Coatbridge. The Veitsch Company are far away among the Austrian Alps. A panoramic view of these is exhibited. The works are five or six miles from any railroad and all their bricks and bags of magnesite have to be carted through a narrow valley to the Murs Valley where the lines run either east or west, either to Trieste, which is shown on the map, where shipments take place or towards Vienna where the railway lines distribute the goods to the various consuming centres. Shipments at Trieste are very difficult just now. Steamers take a long time to load. There are very few locomotives in the country. Such as there are, are using wood logs as fuel. You can imagine how much steam we could keep on our main boiler if we had only wood to burn. You can imagine how many carriages could have come from Coatbridge to Lanark today if the engine had logs of wood to burn instead of coal. I met a man recently, the representative of a very large Paris and London firm, who told me his principal was travelling from one end of Austria to the other, and also in Germany and that it was an ordinary occurrence for trains to stop between stations and for any timber near at hand, either fences or gates, or even parts of the carriages them, selves to be collected by the passengers so as to provide enough wood to steam the engine to the next station. My brother law is in that part of the world just now, and he tells me that the trains travel with only one-third of the usual carriages and that even though you have been travelling for two days and two nights in succession and are tired out, you can’t sleep in the trains for the shaking, and the jolting.

While they have plenty of food in the country districts, the food in the cities sells at ransom prices. They have no transport facilities. Coal costs anything from £15 to £20 per ton. You can imagine, therefore, with no coal supplies how many kilns they can with logs of timber, and how many tons of dead burned magnesite and magnesite bricks they can supply. Of course, their competition is bound to come later, and it is for that reason that we are doing all that we can overtake to get erected good milling plant and good calcining plant so that we can do at our works all that they can do at theirs. When our plant is erected it will be up to the workers to work the plant with the highest skill. Your will compete with the labour of the Continent to do the work to the highest standard and as economically as possible. Wages will not come down until the cost of living is greatly reduced, but all workers should consider whether they cannot give a little more production. That may only be possible if the machinery or plant is altered so as to suit better the labour being done. The intention with us will be to give any proposal that is put forward by any of the workers in that way every consideration possible. Now, there is no use of speaking in generalities without giving an application to those general ideas, and I would like to refer in a few words to two matters that I know have been very much on the mind of our works manager. One of these has to do with the percentage of rejected magnesite bricks and the other has to do with fuel consumption.

I think the workers are to be congratulated on their having fixed an annual dance as you did last winter and also on the annual trip which you are beginning today. Whoever it was who originated the idea deserves credit. I shouldn’t be surprised if it was Maggie Toal and if it was, her name should be remembered and go down to posterity in the history of the works. I am more glad still that you are having such a fine day. I think the committee acted wisely in having a set dinner and afternoon tea, as they have done, and also in deciding that for this year they would have drives rather than sports. Perhaps for next year, now that the minds of the workers have become accustomed to the idea of an annual trip they will set themselves to begin to lay up for six months ahead of the trip, and if so they will be able to go further afield, either by train or by motor transport. There is nothing like providing well beforehand, and perhaps you will let me provide you with an idea about next year’s trip. That is, that it should be a trip either to the head of Loch Lomond or to Dunoon so that you could have a complete change of air and a good dose of sea breezes. I think you have been fortunate in choosing Lanark this year so that you can all get to know the county town of our county of Lanarkshire and to know the Falls of Clyde in the neighbourhood. This is one of the oldest burghs in Scotland. It was a place of residence of the Scottish kings before the English invasion of the times of Wallace and Bruce. Some of you may have been at Stirling and know the William monument. You can also see a statue of Wallace before the church steeple in the square. Wallace was one of the greatest men of Scottish history and though he wasn’t born here (he was born at Elderslie near Paisley) his young wife, Marion Bradfoote came from Lanark and it was at Lanark he first became prominent and famous. That’s a long time ago, seven hundred years ago and more, but it is undoubtedly due to his tremendous energy that the Scottish people retained their self-esteem and strength of character during a series of most trying experiences – The Scots came out well. I think it is a somewhat similar experience on much vaster lines that the whole people of this country of ours are emerging from. The recent war was a tremendous experience for all of us while it lasted. But I believe that we have all gained in strength of character and the best way to show that is in the work that we each of us do. Mr Lawson Scott, works manager thanked Mr Donald for his presence and interesting statement.

27/11/1920 – Airdrie and Coatbridge Advertiser – Boy wanted at once for Works Office. Good at figures. Apply Dundyvan Brickworks, Coatbridge.

24/10/1921 – The Scotsman – The Eglinton Silica Brick Co Ltd (in voluntary liquidation) The subscriber having sold the works and business of the above-mentioned company to the Eglinton Magnesite Brick Company Limited as of 27/09/1921 ceased to have any interest therein from the said date. All persons having claims against The Eglinton Silica Brick Co Ltd or the subscriber as liquidator, thereof, are requested to lodge them with him within 10 days from this date. David Guthrie, C.A Liquidator. 31 St Vincent Place, Glasgow. 20/10/1921.

08/04/1922 – Airdrie and Coatbridge Advertiser – 1914 Overland for sale. In splendid condition with a new body and a complete new hood. Price wanted £140 or best offer. Can be seen at Eglinton Brickworks, Dundyvan, Coatbridge.

10/03/1923 – Airdrie and Coatbridge Advertiser – Dean of Guild Court. The Eglinton Magnesite Brick Company presented plans for the erection of a storage shed, a broken brick store and a women’s mess room. No objections were offered and a warrant to proceed was granted. The cost is estimated at £1200.

14/04/1923 – Airdrie and Coatbridge Advertiser – Required shortly contractor to undertake the discharging from wagons and loading into a shed of approximately two thousand tons of magnesite in bags: Full particulars may be obtained from The Eglinton Magnesite Brick Co Ltd, Coatbridge.

08/12/1923 – Coatbridge Leader – Dean of Guild Court. The Eglinton Magnesite Brick Company submitted plans for roofing in a portion of their works, and the erection of a joinery shop at a cost of £150. The lining was duly passed.

15/07/1924 – The Scotsman – Court of session … Eglington Silica Brick Co Ltd (In liquidation) V H. G. Marrian (Inspector of taxes – for the opinion of the court ( No further details).

1926 – 1927 – Eglinton Chemical Co., Ltd.

11/06/1927 – Coatbridge Leader – James Donnelly, labour, Douglas Street pleaded guilty of having on 12th, March represented that he had no income and received 28s as relief for himself and his wife and six children from Old Monkland Parish Council, the truth being from 10th to 15th March he was employed in the Dundyvan Brickworks of the Eglinton Magnesite Brick Company and earned, £3 10s 2d … He was fined 40s, the option being 20 days in prison and allowed 14 days for payment of the penalty.

1928 – Eglinton Silica Brick Company Limited, Dundyvan, Coatbridge owned by the Eglinton Chemical Company in 1889 and managed by J.A. MacDonald. It was one of the few Scottish brickworks to specialise in making silica bricks. In the 1914 – 1918 war when the supply of Austrian magnesite was cut off, the brickworks turned to burning Greek and Manchurian raw magnesite. It was known as the Eglinton Magnesite Brick Company in 1928. Source Kenneth W Sanderson.

19/03/1930 – Dundee Courier – Valuation Appeal Court, Edinburgh … Appeals which were persisted in by the Inland Revenue and which were allowed by the court were those relating to … Eglinton Magnesite Brick Company Limited, Coatbridge.

02/05/1931 – Airdrie and Coatbridge Advertiser – For sale, a large quantity of brick packing cases suitable for firewood. Eglington Magnesite Brick Co Ltd, Coatbridge.

28/11/1936 – Coatbridge Leader – … Councillor Rankin instanced the Eglinton Magnesite Brick Company as another concern from which a once busy industry had been transferred. He understood the local works were now only used as a store …

05/01/1938 – Coatbridge Express – Death – March 31st at ‘Birnieha’, Shawhead. Mr Charles Rigby, manager of the Eglinton Magnesite Brick Company Limited, Dundyvan Road.

Below – 1939 – Eglinton Magnesite Brickworks.

21/01/1939 – Coatbridge Leader – Bernard Donnelly, unemployed ironworker, 10g Kirk Street, pleaded guilty of having stolen, on 11th January, 2cwts of coal from a cellar at Dundyvan Brickworks, belonging to the Eglinton Magnesite Brick Company. Mr Denholtm said that Donnelly was seen in the cellar at about 1.50 p.m. removing coal. There were two bags outside each containing about 1 cwt. He was warned and charged at the time but made no reply. “It was a rather a cheeky thing to do,” the Fiscal commented. Donnelly excused himself on the ground that he had a boy lying sick at home, and that there was no coal in the house. He was thus forced to go out and find some, he said. He was in receipt of benefit from the Employment Exchange he admitted. Judge Mullen said that he had every sympathy with an unemployed man because he knew that relief did not enable the recipient to procure all necessities, particularly coal which was so dear, but he could not condone stealing. The people who owned the coal had to purchase it themselves, and they thus suffered loss by such thefts. Accused said that was the first time he had done such a thing. A fine of 5s or five days imprisonment was the penalty imposed, a fortnight being allowed for payment of the fine.

Below – 03/08/1940 – The Scotsman – Eglinton Magnesite Brick Company Limited, Dundyvan Brickworks, Coatbridge in voluntary liquidation.

10/08/1940 – Coatbridge Leader – Dundyvan Brickworks closing down. Eglinton Magnesite Company suspends operations. The Dundyvan Brickworks of the Eglinton Magnesite Brick Co.. Ltd., are to close down for good next week. The company, which dealt in bricks of purely Austrian origin first started operations in Coatbridge in 1921, but since the outbreak of the war, and indeed for some time before that, there had been a considerable falling away of business in its special line with the result that, the company is now winding-up. Its Coatbridge Works, which are situated at the south-east end of Stobcross Street and right behind Dundyvan Iron Works, were used mainly as a Scottish depot and in prosperous times, big shipments of magnesite bricks were received there from the continent. Up till a little over three years ago, the concern was managed locally by the late Mr C. L. Rigby. While latterly Mr James Graham has been looking after the firm’s interests. We understand that Messrs William Martin, Sons and Co, Dundyvan Iron Works, are likely to acquire the site and part of the dismantled works.

02/11/1940 – Coatbridge Leader – Refuse seen burning during black-out … A caretaker who left a fire burning during the hours of darkness in the yard formerly used by the Eglinton Magnesite Brick Company Limited, in Stobcross Street, Coatbridge, appeared before Sheriff Gillies at Airdrie on Monday when a big number of pedestrians, householders and occupiers of various types of premises were dealt with for contraventions of the Lighting (Restrictions) Regulations. The respondent above referred to was John Lang, 2 Central Avenue, Broomhill, Glasgow and he pleaded guilty of the offence charged against him. Lang, in extenuation, told his Lordship that he had been burning refuse and thought that the fire would have died out before the ” black-out ” hour. Sheriff Gillies, in imposing a fine of £2, remarked to Lang that it was a very dangerous thing to do.

1942 – 1943 – Eglinton Magnesite Brick Co Ltd. Brick and Tile Maker, Dundyvan.

Plastic clay was a raw material that was used as a bonding material in the silica-brick trade. British Geological Survey Petrology Collection sample number MC 7443. It is recorded that in the 1870s the Eglinton Silica Brick Company Limited, 43 Renfield Street, Glasgow used plastic clays to bond silica bricks made from flints either imported from the Thames area or northern France and that the bricks were bonded with highly plastic clay from South Wales. The resulting bricks were used in steelworks. There is no evidence that plastic clay from this locality was worked, though it was collected during exploration for natural resources.