Scottish Fire Brick Company, Middlesbrough.

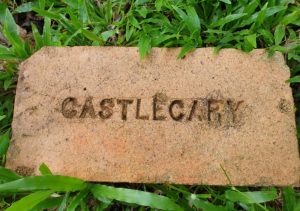

The newspaper articles below refer to the “Scottish Fire Brick Company”, Middlesbrough and a Mr McLauchlan appears to be a director in 1887. It is believed that Mr McLauchlan is Mr Joseph McLauchlan, Middlesbrough. He was an agent for the Castlecary Fire Clay Works, Scotland. (Note – SBH – So was there really a company called the “Scottish Fire Brick Company” operating out of Middlesbrough or was it a reference to the Castlecary Fire Clay Works, Scotland?).

22/01/1883 – Daily Gazette for Middlesbrough – A new industry for Middlesbrough. Today (Monday) the Middlesbrough Fire Brick Company commenced operations at their new works in the Marshes, Middlesbrough. Fire bricks have always been an important factor in the iron and steel trade. Until within the last five years, the cheap fire bricks from the Durham coal fields were almost invariably used in the Cleveland district for the linings of blast furnaces, cupolas for puddling and mill furnaces, and in other places where great heat was to be withstood. For some time past, however, the Durham bricks have been gradually displaced by the higher class bricks from the Leeds district, from Stourbridge, and from Scotland for all important positions as a fire resister. The Scotch bricks are used at the Steel Works at South Bank, and other firms in the district distribute their orders for thin best bricks principally between the Leeds and Scotch makers. The Durham and Newcastle bricks are now but little used, except for parts least exposed to great heat. The great advantage and economy of using the best bricks is easily understood when we compare their duration, say, in an ordinary puddling furnace. An ordinary Durham fire brick will only last from three to four weeks, whilst the best Leeds and Scotch vary from nine to eleven weeks in a corresponding position. The cost of material and labour in rebuilding the furnace, the loss of time, and the continuous patching up amount to a serious item, and have caused ironmasters to be very careful in the quality of the brick they use. The Middlesbrough Fire Brick Company’s new works are situated between the Linthorpe Iron Works and Ayrton Rolling Mills and stand upon about an acre of ground. On the south side, they are connected with the North-Eastern Railway. They are also attached to the Middlesbrough Owners’ private lines to the ironworks and wharves on the river between Newport and Linthorpe Ironworks. The works consist of a large gantry for stocking their raw material (capable of holding 2,000 to 3,000 tons of clay &c), engine-house, millhouse, with large edge running stones, a pug mill, a mixing pan, elevators, &c. The drying shed is a substantial brick building capable of drying about 100,000 ordinary bricks per week. The three burning kilns are of the cone shape, and have been built by the celebrated kiln builder, Mr Robertson, of Glasgow, and are specially arranged to burn the bricks at an intense heat. There are three lines of rails inside the works to the gantry, mill house and kilns. Arrangements are also made for enlarging the works should it be deemed advisable. There is little of an experimental character about the undertaking. The managing partner of the Castlecary Fire Clay Company (of Scotland) is a director of the Company and one of the largest shareholders for some time past. Bricks made from the clay which the new Company are using have been used in considerable quantities in Middlesbrough, and are well known. In addition to the Scotch fire brick, the firm also intends producing ganister fire bricks and ganister prepared for use in the Bessemer converters. For some time past this latter material, which is largely used in steel works, has come from Sheffield, but the new firm has been experimenting with the local ganister, and are, we understand, producing an article equal in quality and identical in analysis to the best Sheffield ganister.

28/09/1887 – Daily Gazette for Middlesbrough – Today at the Middlesbrough Petty Sessions William Wilson was charged with stealing a number of sacks, the property of the Scotch Fire Brick Company, and further with receiving the sacks knowing them to have been stolen. Thomas Campbell, secretary of the Company, said that prisoner had till recently been in the employ of Mr McLachlan, coal merchant, Middlesbrough. Mr McLachlan was a director of the Scotch Fire Brick Company, and the prisoner, as his servant, had had frequent business at the Company’s works. The witness had seen the bags (produced) safe at the works on the 19th inst and had given no authority to the prisoner to take them away. James Rankin, foreman at the Brickworks spoke to giving 24 bags to the prisoner for Mr McLachlan. The prisoner called two youths who stated that they received the bags for the prisoner. Chief Constable Ashe said 85 bags were found in the possession of the prisoner, who, he asked, should be remanded for further evidence on the charge. The prisoner was remanded until Monday next.

10/03/1888 – Sheffield Daily Telegraph – It is satisfactory to note that in some quarters there is a great improvement in trade. One local firm, Messrs. J. Grayson, Lowood, and Co., of Attercliffe and Deepcar, have so large a demand for their silica bricks, that they are making a considerable increase in their plant at their Deepcar Works, and have also purchased A large brick works and plant at Middlesborough-on-Tees. This latter establishment, which has been worked by the Scotch Fire Brick Company (Limited), will be known as “The Lowood Wharncliffe Gannister Brick Works,” and will be carried on as a branch establishment to the Sheffield and Deepcar Works. The raw material used in the manufacture of the silica bricks and other goods will be obtained from the firm’s Wharncliffe Quarries at Deepcar, and manufactured by workmen from their regular staff. By these means, Messrs. Lowood and Co. will be enabled not only to execute orders with promptitude, but also to make the quality of the goods supplied from Middlcsborough equal to those manufactured in Sheffield. This speciality so closely associated with the iron and steel trades has made a very rapid advance of late years.

26/03/1888 – York Herald – New ganister brickwork. The works of the Scotch Fire Brick Company on the Marshes at Middlesbrough have been sold to Messrs. J. Grayson Lowood and Company,- of Sheffield and will in future be carried on as the Lowood Wharncliffe Ganister Brickworks. The material from which the silica bricks for steel works will be made will be brought in its raw state from Messrs. Lowocd’s Wharncliffe Collieries at Deepcar, near Sheffield