Manuel Works, Whitecross, Linlithgow, Stirlingshire.

- Stein, Castlecary Fireclay Works, Castlecary, Stirlingshire.

- Stein, Manuel Firebrick and Refractory Works, Whitecross, Stirlingshire.

- Stein & Co, Anchor Brickworks, Denny, Stirlingshire.

- Milnquarter Fireclay & Gannister Works, Bonnybridge, Stirlingshire.

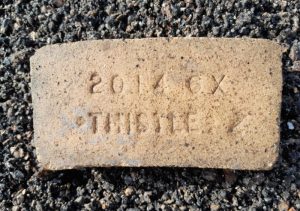

Below – Brick sign at the entrance to the works.

Canmore

Information by David Leask

Information – Falkirk Community Trust.

02/1928 – Work begins on draining the site.

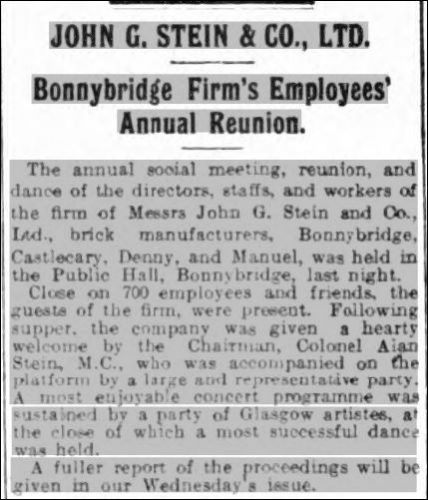

Below – 23/02/1929 – Falkirk Herald – John G Stein annual social outing.

Below – 22/03/1930 – Falkirk Herald – Messrs John Stein and Co., Ltd., Castlecary, Bonnybridge, and Denny will open in six weeks’ time their large new works at Manuel which have taken about two years to construct. While the manufacture of bricks cannot be properly classed as one of the vital industries of the area, it is nevertheless an increasingly important means of employment for a very large number of breadwinners who would otherwise be compelled either to travel further afield to their daily task or perhaps be unable to find employment all, especially in view of the continued depression in the building trade. The new works, it has been stated, will provide an additional output of 30,000 firebricks per day, a task which obviously cannot be achieved without the extensive employment of labour. When it is learned that during the past year the firm’s works at Castlecary and Bonnybridge were called upon to work at full capacity, the immense importance of this industry is at once realised in an area like Falkirk, where the shadow of unemployment and slack time has long been accepted as inevitable. Colonel Alan Stein, in addressing his employees, very wisely stressed the importance of encouraging the saving habit both from the individual and national point of view. The general lack of prosperity throughout the country has had a marked effect on the building trade. Houses are still too dear to be let at economical rents, and before there can be any genuine revival in the building trade all concerned will require to give better value. There is no one who will deny the truth that production in this country is unable to compete in price with foreign-made articles, and if an increased volume of export trade is desired, prices will require to be cut to the approximate level of the competing goods. In view of this difficult, but by no means insuperable obstacle, a matter which reflects great credit to both employer and employees that to the present there has been no noticeable decline in the brick manufacturing industry of the district. If such a healthy condition of things existed in the more staple industries of the area there would be cause for universal satisfaction.

19/03/1930 – Falkirk Herald – Messrs John G Stein & Co, brick manufacturers employees annual social reunion… Col. Stein on rising to address the company, was accorded an enthusiastic ovation. He said that it gave him much pleasure on behalf of his brother and himself to welcome those present to their eleventh annual social meeting and dance and he hoped that it would prove to be as enjoyable as the previous functions. It was customary to take the opportunity when they were together to say a little about the firm’s business and prospects. Denny Works had only been working at half capacity during the past twelve months and with the continuation of the depression in the building trade he did not see any prospect of improvement at present. The lack of prosperity throughout the county had, of course, its effect on the building trade but apart from that, houses were still too dear to be let at economical rents and all concerned in the building trade were required to give better value before there could be a genuine revival in house building. Their principal business was the manufacture of fire bricks and silica bricks and the Castelcary and Bonnybridge Works had been working at full capacity during the past year. They had reason to be thankful for that as the industry throughout the country had not been well employed. As they all knew, the firm had been building large new works at Manuel during the past two years. He was pleased to say that these works were now nearing completion, and would be in production in about six weeks’ time. They had about 185 men on the payroll at Manuel at the present time, but owing to the limited accommodation of the hall, which was already taxed to the utmost, it was not possible to have the Manuel employees with their wives there also. They regretted that very much, but hoped next winter to have a separate social meeting in Falkirk or Linlithgow for them. They were delighted, however, to have the staff from Manual with them that night. (Applause.) The new works at Manuel would give additional output of 30,000 firebricks per day, and perhaps they would wonder how they were going to dispose of the additional output in these times. Well, it could only be done by a continuation of the firm’s policy of striving always to give better and better value. The new laboratory would be finished in about six weeks’ time, and this new laboratory would give the research workers better facilities for carrying out their work. He believed the provision of the additional productive capacity would act as a stimulus to them all to give of their best, and ensure that they least deserved the extra business. (Applause.) If they did that believed they would get it. He might be expected on an occasion such as was afforded that night to say a word about unemployment. It was a serious problem for their country, the unemployment question. While they had a higher standard of living than in pre-war days for those employed, along with shorter hours, better social services, etc., they had the hardship and demoralisation of unemployment in the case of a considerable number of men and women. In his opinion there were two main factors in the solution which were not yet appreciated by the man in the street. The first factor was that they were not saving enough. It was the savings of the nation that provided capital for improvements, extensions, and new developments, and these all gave employment. The saving habit was therefore a good one, both for the individual who saved and for the nation. The second, and by far the more important, was that the people in this country at the present time were not producing cheaply enough. They had a remarkable and striking demonstration in the recent revival in the coal export trade. That materialised whenever the price of coal was reduced. They must therefore give better value if they were to secure the required extra volume of export trade. This was a matter less for politicians than for those engaged in industry. It was not only a question of rationalisation, where that was being sought as one method of lowering costs in certain industries. It concerned not only those people at the head of businesses, but it concerned every individual worker in the country. (Applause.) The speaker remarked that he was not a pessimist so far as the future of the old country was concerned, but did think they were slow to appreciate the main causes of the present depression to apply an effective remedy …

10/04/1930 – The gas was lit in No 1 kiln and gas producer plant.

11/05/1930 – The first Nettle firebricks at Manuel are produced.

Below – 04/04/1931 – Falkirk Herald – Employee’s reunion – Annual gathering of employees of Messrs John G Stein & Co – Col Stein and the trade outlook. Dinner over and the tables cleared, Colonel Stein rose to address the employees, from whom he received a hearty ovation. In his opening words of welcome, he expressed his regret that it had not been possible to have the employees of the Manuel Works present, as the accommodation the hall was already taxed to its utmost. They, however, had a successful social evening of their own in Polmont a week ago. Continuing, the Chairman said:—We are passing through a very depressing time, and while we have been very successful in the past in providing regular work to steadily increasing numbers, we have had to slightly curtail our output during the last six months. Notwithstanding this, we have as many employees as we had last year but since then we have started our new works at Manuel, and but for the depression, our numbers would have been much greater in consequence. I would like to say a few words, first on the general situation. We are all naturally much concerned about the serious and persistent unemployment, and it is important to try, if possible, to have a clear idea of the cause. I was once told by a distinguished research worker that a problem well-defined is half solved. There are important factors such as the state of affairs in Russia, India and China, and the world depression in trade, but I believe our main problem is that we must get our costs of production reduced. We have failed in this country to adjust our costs to world costs, and we are getting a much smaller share of the export trade in consequence. I have mentioned this before, but “ facts are chiels that winna ding,” and I think this fact becomes more and more apparent as we struggle painfully along. We are handicapped with high wages in many of the sheltered trades. By this, I mean those trades competing for export. The municipal street cleaner gets a higher wage than the skilled engineer. I think, however, there are two principal ways by which we can reduce costs, leaving aside an extension of piecework, for which there appears room, especially in the building trade. First, expenditure of more capital on improved plant and equipment to get greater production per head; second, reduction in rates of wages. The first way, in my opinion, is the desirable method, but apart from a lack of confidence in the future, in this country, we are using up our capital in excessive taxation, and it is not available for new equipment and new construction. The provision of new equipment in itself provides considerable employment. For example, we have been spending capital for two years building new works at Manuel, and roughly speaking, gave employment directly or indirectly to 350 men during those two years, and now when complete we are giving regular employment to others. This sort of thing should be done more in all trades, and all the time, and it would be done, I am sure if conditions permitted. Failing reduction in costs on these lines, I think nothing can prevent a fall in wages, although the solution may come partly one way and partly the other. I believe the ultimate interests of both capital and labour run more on parallel lines than is generally believed, and a proper realisation of economic laws would help us to recover more quickly from the present depression. I turn now to our own affairs. I am glad to report there has been an increased attendance at evening classes our employees last winter. Under the scheme whereby we give a bonus to those who complete the course and gain certificates, 18 of our employees earned bonuses totalling £41 4s last winter. The same scale bonus will be given to employees at Manuel in future. I hope there will be a still greater increase in the attendance at evening classes. I need hardly emphasise the importance of good education, and for those who wish to get on in life, it is quite essential that they should make every effort to improve their education. If we are to maintain a higher standard of living than our competitors we must make the fullest use of the brains as well as the brawn! We had a series of technical lectures at Castlecary Works during the winter. There were nine lectures altogether covering chemistry, physics, and clay technology. The average attendance was 35, and I consider this highly satisfactory. These lectures were given by members of our staff, Messrs Hyslop, Biggs and Malcolm, and I believe they are willing to continue in the same way next winter if they find there is a demand from the employees for them. The idea originated with these gentlemen themselves, and I am sure we are much indebted to them for the trouble they have taken, I have been very pleased to note the improvement in the gardens at Castlecary. This is no doubt the result of the garden competition instituted by Miss Annie Stein two years ago. Other various social activities are going along well. The Scouts, under Scoutmaster Muir, are going strong and had a very successful camp at Arran last year. The Sunday School, under Mr Crawford, continues its good work, and we now have a successful juvenile choir under Mr Benson. The Recreation Club is more popular than ever. The Bowling Club have also had a successful season and the winner of the green championship (bowl presented by Mrs John G. Stein) was Mr Robert Clelland. The works football shield was won this year by the stove department. Since our last social meeting the two most important events for us were the starting of our new works at Manuel eleven months ago, and the opening of our new Research Laboratory eight months ago. The new works are turning out excellent bricks, and we are finding steadily increasing demand for them. We are doing our very best to capture markets overseas previously held by foreign competitors. The new research laboratory will help us to keep abreast of the times, and we have an excellent staff there, under Mr Hyslop. The heavy industries of this country have been the most badly hit by the depression, and this affects the demand for firebricks and silica bricks in which we are most interested. We have, however, had a good share of the business that is available. I would like very much to have been able to tell those who are on short time, or were suspended, that there were signs of the tide turning, but I really cannot do so. We have an excellent team spirit throughout our whole organisation, and I am sure that, especially in these times, you will do your very best that we deserve to get more business. I have confidence in the future of this country. I think we have been too slow to appreciate the greater competition we have now to face for a share of the world trade, but we have excellent workmen and I have every confidence that we will sooner or later face the hard facts, and that we will then see a return to prosperity. At the close of his address. Colonel Stein had to wait for the prolonged applause to subside before he could announce the commencement of the concert. The programme was sustained by a party from Messrs Paterson’s musical agency, Glasgow, and it is safe to say that it equalled, if it did not excel, the high standard attained on previous occasions. In his opening number, “The Stockrider’s Song” (W. A. James) Mr Frank Gordon, bass-baritone, caught the mood of this Australian bush song to perfection, and fully merited the applause he received from the appreciative audience. Later, in “The Trumpeter” (Airlie Dix), and again in that popular old Cornish folk-song “The Floral Dance,” Mr Gordon had full scope for his interpretative powers and established himself in favour from the beginning. In her first solo, “Hungarian Dance” (Drdla) Miss Margaret Smart, violinist, exhibited fine tonal quality and a dexterous bow hand, while in her later numbers, “Two Russian Solk Songs” arranged by Kreisler, and the Weber-Burmester “Waltz,” her technique was admirable, and occasionally when the music demanded, she gave glimpses of clever left-hand work also and proved herself a young artiste of much acceptance and considerable promise. Miss Nettie Sclanders is a young soprano with a fresh unspoiled voice and a useful range. In “The Waltz Song” (Edward German) Miss Sclanders showed clear diction and a sweetness of tone that was in harmony with her charming stage presence. In her later songs, “Ave Maria,” and Eric Coates’ “Bird Songs at Eventide,” this young singer earned whole-hearted applause from her hearers. The “magic” of Mr Claud Williams was at times as mystifying as it was clever, his running patter being a source of continuous merriment, and completing a programme that was thoroughly enjoyed by all present. Miss Barbara Laing at the piano, accompanied the soloists with commendable skill and sympathy. At the conclusion of the concert, Dr Young proposed a vote of thanks to the committee and artistes. He said there had always been two outstanding features connected with the firm of Messrs John G. Stein & Company. The one was the power of organisation, and the other was efficiency. With regard to the former, he asked the employees to accord to the committee who had organised so successful a function, their heartiest thanks. (Applause.) The second outstanding feature was efficiency. They had heard Colonel Stein talking about unemployment and cost of production, and he would like to suggest to Colonel Stein that he should secure the services of Mr Claud Williams, and then he could make bricks out of nothing! (Laughter.) Mr John McConnachie, on behalf of the employees, returned sincere thanks for the generosity of the firm. They were very much indebted, he said, to Colonel Stein for the address he had given them, and also for his resume of the firm’s activities during the past year, which they must consider very satisfactory despite the depression which was so prevalent all over the world. They all hoped and trusted that it would soon pass away and that the firm of John G. Stein & Company would continue to hold the position it had held for many years; that is “second to none.” (Loud applause.) He also asked the audience to accord Mrs John G. Stein a special vote of thanks and to ask their worthy chairman to convey to his respected mother their kindest regards, and the hope that she may long be spared to come amongst them. Mr Norman Stein, although he, unfortunately, could not be with them this evening, was nevertheless an important factor in the firm’s progress, and it gives him pleasure to join his name with those of Colonel Allan and Mrs John G. Stein, He asked them to accord to their employers a very hearty vote of thanks for the excellent way in which they had been entertained tonight. (Prolonged applause.) The call, having received a response, and having been duly acknowledged by Colonel Stein, the first half of the programme came to end. The hall was then cleared for dancing which was carried through to the sprightly music of Mr David Mitchell’s Carron Orchestra, the members of which are to be complimented on their rhythmic melodies and the readiness of their response to encores. The onerous duties of M.C. were jointly and ably fulfilled by Messrs W. Miller, P. Duff and A. Cooper …

10/1931 – A second Harrop, USA kiln was started.

07/11/1931 – Falkirk Herald – Industry in Falkirk … The manufacture of firebricks, which in past years has been numbered among the “hardest hit’’ of all local industries, is giving indications of a return to better times. Messrs J. G. Stein are hoping that with the revival in the steel trade their opportunity will arrive, and the firm is at present engaged in extending their works at Manuel. A number of extra workmen have been engaged. English buyers have discovered that the quality of firebrick manufactured across the border is much lower than that of the Scottish product, and as a result, there is a brisker demand to be met by the local manufacturers …

19/11/1931 – The Research Director, Dr Hyslop took out a patent (361, 166) with regard to the process of oxidising the carbon in the Nettle clay at under 750 deg C to produce a low temperature calcine as the high carbon content of the clay limited the rate of burning the bricks. This process resulted in a greater density brick, branded NETTLE D.

06/1932 – The second Harrop, USA kiln was completed but due to lack of orders, it was never lit until 10/1934.

1933 – 1943 – Dr Hyslop took out a further 4 patents covering different processes involved with the extraction of alumina from fireclay.

16/02/1938 – Falkirk Herald – Large article regarding the firm’s annual gathering. 800 people were present.

08/04/1938 – A 3rd Harrop, USA kiln was completed and the first ‘Stein Glasgow’ fire bricks were manufactured.

Below – 11/09/1943 – Falkirk Herald – Advert announcing the distribution of Christmas gifts to all men and women in HM Forces who used to work at Manuel.

Below – 1944 – 1967 – Manuel Works.

29/06/1946 – Falkirk Herald – Bricklayers wanted for inside construction work; furnace experience an advantage. Apply John G. Stein & Co., Ltd., Manuel Works, nr. Linlithgow.

26/03/1948 – The Scotsman – Houses for workers. Products of high priority. At a meeting of Stirling County Council at Stirling yesterday it was reported that on the suggestion of the Department of Health for Scotland a meeting had been held attended by representatives of the Department of Health, The Ministry of Supply, John G Stein and Co Ltd, members of the local authority and others on the question of the provision of houses for workers employed by Messrs Stein in view of the importance of their products to steel works in this country and as a dollar earning export. Colonel Stein had explained in detail the need of houses for workers at their Manuel Brickworks and their works at Castlecary if their output was to be maintained. Mr Thatcher of the Ministry of Supply explained that his Ministry attached a very high priority to the products of the firm. The chairman, Mr Crow of the Department of Health reported that the Department were prepared to make available to the County Council, 100 Cruden houses on receiving an undertaking that the houses would be allocated to persons employed by the firm and who at present resided in the county …

01/07/1948 -No 4 kiln starts producing bricks.

Below – 24/07/1948 – Falkirk Herald – Government visit to Manuel Works. (Fourth biggest in the world?).

.

.

.

17/11/1951 – Falkirk Herald – Clay Miners required. Wages for 5 3/4 days – £7 13s. This can be further increased by piece work. 12 days paid holidays per year at 27s per day. Experience not necessary. Hostel accommodation is available. Apply Manager, John G Stein & Co Ltd, Manuel Mine nr Linlithgow.

06/1954 – Large scale production of Nettle D was started. (According to Mr K. W. Sanderson).

13/05/1956 – First ‘Nettle D’ bricks are manufactured in the ‘new plant’.

09/1956 – No 5 kiln was started and came into production the following year. It was used to fire high alumina or basic brick as required by the market. Bricks such as the high alumina brand Stein 73 were fired in this kiln. (According to Mr K. W. Sanderson).

03/10/1958 – West Lothian Courier – Fatal accident. When at work in Messrs Stein’s Brickworks (Manuel Works?) on Monday morning, Gilbert Hassel, 5 Avontoun Crescent. Whitecross was crushed by a mechanical shovel, death being due to chest and spinal injuries. Mr Hassel, who was 40 years of age, is survived by his wife and two children. aged 18 and 15.

05/1959 – Refractories Journal – One million 7 per cent cumulative preference shares of £1 each in John G. Stein and Company Limited have been offered for sale at 20s. 6d The company was converted into a public company on 30th April. In a letter to Glasgow Industrial Finance Limited, the chairman, Mr Colin H. Stein states that the directors have consistently pursued a policy of building up reserves, subject to payment of reasonable dividends, to meet the cost of a continuing programme of expansion and development designed to improve the quality and quantity and reduce the cost of the company’s products. Over £1, 600,000 has been spent on land, minerals, buildings, plant and houses during the five years ended 31/12/1958. Existing plans for the next stage of this programme cover 3 years ahead and further developments beyond that period are in contemplation.

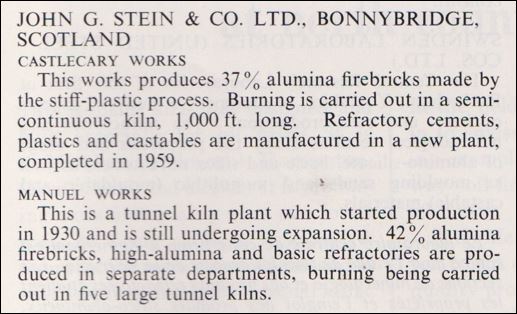

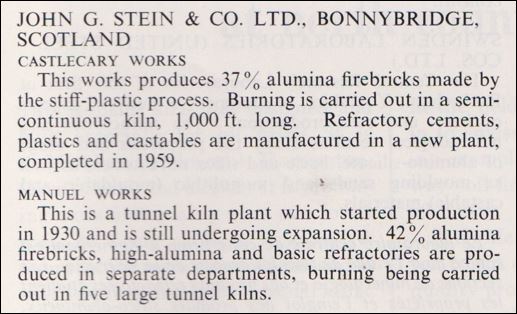

Below – 05/1960 – The Refractories Journal – Semi-continuous kiln 1000 feet long.

11/1960 – Refractories Journal – Refractories and brick manufacturers in Scotland are currently reorganising on transport operations to eliminate ‘Contract A’ licences and to replace these with the employment of a contractor on normal commercial lines. Under the ‘Contact A’ basis, the employing company guarantees the contractor a given revenue annually and the vehicles are exclusive to the employing company. Defects of this method of operation are that the contractor cannot carry return or other loads and so it is denied earning power which means that the rates to the hiring company are maintained at a higher level than need be, were return loads available and the costs spread over. In return, the hiring company has an exclusive call on the vehicles, but it has been a general policy in recent months to dispense with that exclusive right and to seek service on a keener price basis from the same contractor who is normally prepared to accept that basis since it gives increased scope for earnings. A simple declaration by the hiring company that it wishes to terminate the contract is sufficient evidence to allow this to be done, and a number of such cases have been heard in the Scottish area affecting companies in the industry. At Glasgow Court on 7th November, Joseph Hunter and Sons of Polmont were authorised to put 13 vehicles of 55¼ tons off ‘Contract A’ on to ‘Ordinary A’ when the hiring company John G. Stein and Company Limited gave evidence e of a desire to switch to normal usage. Darngavel Brick Company Limited, the other user had previously made a similar statement. The vehicles will continue to be used on brick and refractories and raw material traffic for these clients but on a free basis. In evidence, it was stated that the Waldhouse mine of John G. Stein and Company was expanding and would double its output by early 1962. The case for the two companies was that their adjoining properties and works allowed scope for interchange of vehicles as the need arose and this was granted.

04/5/1962 – West Lothian Courier – While working overtime at Manuel Brickworks. Whitecross, on Wednesday. 38-year-old bachelor George Ainslie, 12 Braehead Place, Linlithgow died from extensive injuries received when he was crushed by a hydraulic shovel.

1963 – No 6 kiln was built.

Below – 03/12/1963 – The Scotsman – John Stein advert for cements, plastics and castable refractories.

1965 – No 7 kiln was built.

Below – 15/01/1965 – The Scotsman – Advert for a Design draughtsman at Manuel.

1967 – Hepworth Ceramic Holdings plc (HCH) purchases John G Stein & Co Ltd. and merges it with its refractory subsidiary General Refractories Group.

Below – 23/01/1968 – The Scotsman – Advert for a design draughtsman at Manuel.

Below – 16/09/1968 – The Scotsman – Advert for welders at Manuel.

Below – 26/09/1968 – The Scotsman – Advert for maintenance fitters at Manuel.

11/1968 – Refractories Journal – Mr Matthew Dick has been appointed works manager at John G. Stein & Co’s Manuel Works at Whitecross. Educated at Falkirk High School he did sailing engineering time and was then on development work before becoming assistant works manager at Castlecary. He did management studies at the University of Glasgow and has been works manager at an associated plant at Glenboig.

Below – 27/12/1968 – West Lothian Courier – Advert for an auto electrician at Manue,

28/11/1969 – GR-Stein became a subsidiary of Hepworth Ceramic Holdings Ltd.

1970 – Hepworth Ceramic Holdings Plc renames the merged refractories group as GR-Stein Refractories Ltd.

Below – 30/04/1970 – The Scotsman – Advert for a design draughtsman at Manuel.

Below – 13/06/1970 – The Scotsman – GR-Stein Refractories Ltd advert for Firebrick Manager and Shift Manager.

Below – 22/05/1972 – The Scotsman – Advert for an occupational health nursing sister at Manuel.

Below – 02/11/1973 – West Lothian Courier – Advert for laboratory assistants at Manuel.

Below – 18/01/1974 – West Lothian Courier – Advert for bonus clerkess/typist at Manuel.

Below – 15/03/1974 – West Lothian Courier – Advert for maintenance fitters, pattern maker, process operator and clerkess at Manuel.

Below – 24/05/1974 – West Lothian Courier – Advert for engineering foremen at Manuel.

Below – 19/07/1974 – West Lothian Courier – Advert for an assistant production control clerkess at Manuel.

Below – 02/08/1974 – West Lothian Courier – Advert for female laboratory assistant at Manuel.

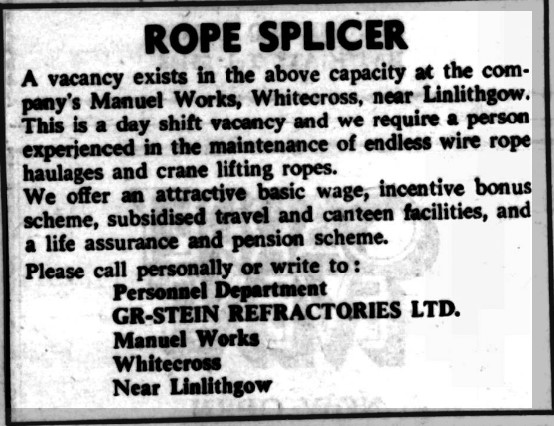

Below – 07/02/1975 – West Lothian Courier – Advert for a rope splicer at Manuel.

Below – 21/01/1977 – West Lothian Courier – Advert for Maintenance fitters and pattern makers at Manuel.

Below – 20/05/1977 – West Lothian Courier – Craft apprenticeships at Manuel.

1985 – HCH comes to an agreement with British Steel Corporation (BSC) to merge its refractory subsidiary, GR-Stein Refractories with the BSC Refractories Group. HCH would own 78% and BSC 22% of the enlarged refractories group.

1987 – HCH purchases Thos. Marshall (Loxley) group and Belref Group, both are major refractories producers.

1988 – Hepworth Ceramic Holdings Plc is renamed as Hepworth Plc. Hepworth renames the combined GR-Stein (including the former BSC Refractories works), Marshall and Belref refractories group as Hepworth Refractories Ltd. with its headquarters in Sheffield and with a European headquarters in Saint Ghislain, Belgium.

1991 June – Two French insulation brick companies – Les Produits Siliceux (LPS) and Constructions Thermiques Europeennes (CTE) were added to the refractories group. MPK’s Insulation’s Colchester works closes in October.

1996 – Hepworth states in its annual report that it’s seeking a buyer for its refractories subsidiary.

1997 April – Alpine Inc a USA company buys Hepworth Refractories for £63.9m (£62.5m plus £1.4 intercompany debt repayment)

1998 April – Alpine Inc having just bought an American refractories group, American Premier Refractories, merges this group with its Hepworth Refractories subsidiary and forms a new company called Premier Refractories International. American Premier Group included BMI-France, American Premier, Premier Refractories Canada, JH France and Findlay Refractories among its subsidiaries.

1999 May – Cookson Plc purchases Premier Refractories International (PRI) for $115m plus $293m in debt. Cookson merges PRI with its refractories subsidiary Vesuvius. Cookson had bought Vesuvius Crucible Company in 1987 and expanded that group by acquisitions which included buying Flogates / KSR group in 1998. Cookson continued to purchase and divest. UK Foundry specialist Foseco was purchased in 2008.

13/05/1999 – The Scotsman – Cookson pays £252m for Alpine division. Cookson Group, the industrial materials specialist which has been selling unwanted businesses, has signalled its plans to return to growth with news of a £252 million acquisition in the US. The cash has been spent on acquiring Premier Refractories International, a subsidiary of Alpine Group, which has a special niche in supplying linings for furnaces in the steel, glass and other industries. Stephen Howard, the Cookson chief executive, said that the business is complementary to his group’s existing Vesuvius operation which has a major plant at Glasgow and supplies heat-resistant plumbing equipment to similar customers. Cookson has raised more than £160 million from the sales of businesses in the past 18 months. Premier which employs 3,500 people in North America, the UK, France and Belgium, made £16.5 million profits on £226 million sales in the nine months to the end of January. Cookson directors said that they could see substantial benefits for merging the business with Vesuvius and expected the deal to enhance earnings within the first year. Following the acquisition, Cookson’s total operations in the refractory market will have annual sales of about £700 million with more than 70 manufacturing sites and employing more than 8,000 people. As such, it will rival the group’s.main business in supplying materials to the worldwide electronics industry. The deal is expected to be cleared by the end of this month. Cookson is paying £181 million cash and the remainder will be met by the issue of new shares at 183p each. Cookson’s shares responded with a 3.5p rise to 184p.

2001 – Works closed.

Below – 18/09/2001 – The Scotsman – Manuel site for sale. 120 acres

2012 – December Cookson group floats its refractory division as Vesuvius Plc And renames the rest of the Cookson group as Alent Plc.

2020 – Vesuvius Plc remains an international leader in the refractories industry and continues to make and sell its legacy brands such as Nettle, Stein, Sillmax, Alro, Supermag, Contex, Durax and many other GR-Stein brands though most of them are manufactured in plants outside of the UK.

**********************

Some additional insight – Eric Flack states – From 1959-1965, I used to work for a consulting analytical chemist in Glasgow. They specialized in chrome ores amongst other things. Steins Manuel Works used to import Masinloc Chrome Ore ground to under 1/4 mesh. It came in 4,000 ton “lots” as ships ballast in the Ben Line-mainly. I would spend a few days each month sampling the ore. It went mainly by lorry to Whitecross and sometimes by rail; via the tippler at Manuel. The chrome was around 32-35% Cr203 and 20-25% Al2O3. They made a very heavy Chrome refractory brick. Stein also imported ilmenite from Rhodesia and Rhodesian Chrome. They sometimes bought Turkish chrome but it was not so good. But mainly Masinloc Chrome Ore. Then went to work with British Steel where I did a weekend shifts-extra overtime- rebricking electric arc furnaces! With Stein’s chrome bricks!

**********************

Below – Date unknown – Aerial view of the Manuel Works.

Below – Source Falkirk Heritage and Archives.

J G Stein, G R Stein and Hepworth Ceramic Holdings.

Castlecary Brickworks, Bonnybridge, Falkirk

Established November 1902 – 1979

Construction at the yard began in November 1902 with the works finally opening in April 1904.

In the 1920s the Company was hit by the depression and this adversely affected the demand for fireclay and silica bricks. Stein, however, retained a good market and opened a research laboratory in 1930.

In 1937/38 further expansion was completed and Castlecary became the head of GR Stein’s Scottish Operations.

1970 – JG Stein & Co Limited merged with General Refractories Limited and became a member of a group headed by Hepworth Ceramic Holdings Limited. During the remainder of the 1970s and despite the selling up of a ‘special products’ unit, the site was slowly run down.

1980 – Main offices closed and shortly after, all production.

Raw materials – Fire bricks were made from raw materials found in a fireclay mine in Castlecary Estate and leased from the Earl of Zetland.

Products – Production of firebricks and phosphate bonded refractories. A range of Tenemax domestic storage heater blocks. Also, refractory cements and monolithics including mouldables, gun mixes, ram mixes and concretes.

*******************************

Below – 03/01/2002 – The Falkirk Herald

THE END

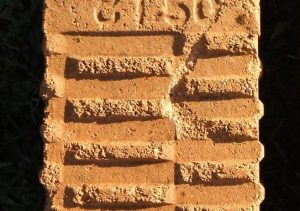

Two words imprinted on one of the last bricks ever made at the former GR-Stein works in Whitecross.

But that simple memorial does not even begin to tell the story of a remarkable workplace renowned throughout the world and loved throughout Falkirk district.

Only a skeleton staff now remain at Manuel Works, near Whitecross there to see the once-grand site recede into shadow along with the memories of the people who worked there.

Their industry and toil made the brickworks famous. But in the end, they were not enough to keep it open.

At its peak, there were more than 1200 employed there almost everyone in the district had a relative who found their way to the works, some for a summer, others for a lifetime.

Its passing marks the end of one of the last great family employers. Generations of families worked at Manuel and helped make it a success.

Workers no longer throng in and out of the gates, but their voices and spirit still echo in the site.

It opened in 1928 and eventually rose to become a world leader exporting to 120 countries.

Operations Manager Robert McMeechan (56), of Stenhousemuir, will be the last to leave. He has overseen the shutdown since it was announced 15 months ago.

He told the Herald: ”Most of the people had worked here for 20 to 30 years they spent a lot of their lives here.

”The place was full of families. It was a great family place. It s good for your business to have families. They re all looking after each other, but they re also making sure they re all doing what they should be doing.

”It was a haven for people, to be honest. There were a lot of people from universities who came for the summer.

Around 240 people were employed at Manuel when the closure was announced, a far cry from the 1200 employed in the early 1970s.

But the effort of the workers who remained throughout the closure period never faltered as they completed orders to be sent to America and Chile.

Robert said: ”The workforce was excellent, they did brilliantly. They kept working right until the end.

”The quality was so great, they were coming here to get the last orders. People from the entire world wanted bricks from here before it shut down.

Manuel exported to 120 countries mostly through Grangemouth Docks. Raw materials came to Whitecross from across the globe.

In a good year, around 100,000 tonnes of bricks were produced. Manuel Works won the Queen s Award for exports in 1987.

It produced refractory bricks, for furnaces, and monolithics concretes and cements to put the bricks together. Brick production has been shifted to Poland, while the monolithics have gone to Chesterfield.

Its products were used for the making of steel, cement, glass and aluminium.

Robert said: ”The Manuel quality is why we were the best in the world, but you reach a stage where you re not competitive. It doesn’t matter how efficient you are.

The works, which occupy a 122-acre site, were founded in 1928 by the legendary John G. Stein.

”John G. Stein had a lot of foresight, knowledge and skills, said Robert.

In the late 60s, the Stein family agreed to a merger with General Refractories and became GR-Stein.

The Stein family left a short time later, but the name lives on and will continue to do so. Even though the brickworks have shifted to Poland, the products will continue to bear the famous Stein brand names.

Hepworth Refractories took over in the 1970s, Alpine made it Premier Refractories around 1997 and current owner Vesuvius took charge around three years ago.

Works at Castlecary, Glenboig and Chapelhall closed in the early 80s and everything was centred at Manuel Works.

”Now it s Manuel’s turn, mused Robert.

His grandfather, father, uncles and brother, William who was made redundant in the closure all worked at Manuel.

Roberts role is now to wind up Manuel and oversee the last couple of orders going out and equipment being shipped away.

He started in June 1961 as an apprentice electrician and remembers the many ”fantastic characters.

It was his task laterally to ensure the shutdown went as smoothly as possible. He said he was glad training took place to help workers find other employment.

Robert said: ”I’ve had to live with this for a long time. There has been a closure programme for 15 months. I just had to focus on the job.

Pre-cast operator John McLeish (51), from Falkirk, was one of the many made redundant. Fortunately, he recently secured new employment after 22 years at Manuel.

”I made a lot of friends up there, he said. ”You really miss your workmates. I enjoyed the work I did. It was a good job.

He described the feeling of looking for a new job as ”soul-destroying and said it affected his whole family, however, he is looking forward to 2002.

”It was a strange feeling when I knew I wasn’t going to go back to that place, he recalled. ”I feel sorry for some of the guys who had been there since they left school. It s all they’ve ever done.

He said he had kept in touch with former workmates, some of whom had become like family.

Braes councillor David Speirs described the closure as a ”dreadful blow for the area.

”It’s genuinely sad, he said. ”I know a lot of people who worked there. People with families and mortgages.

However, he expressed hope that new employment could be created in the area.

Ian Imrie (46), convener for the Transport and General Workers Union at Manuel, said it was a ”sombre atmosphere towards the end.

He paid tribute to the workforce for working through the difficult closure period.

”The workforce bent over backwards to help the company out in the last year, he said. ”If it wasn’t for the workforce they would never have got out the orders.

Mr Imrie is now seeking employment. It is a plight he shares with many of his former workmates.

Below – I believe this is a photo of a similarly marked brick

…….and this too – Annet House Museum Linlithgow

Extracts from the newspapers at the time of Manuel’s closure

“Today (Friday) marks the end of an era when the lights go out for the last time at Manuel Brickworks in Whitecross.

The facility has employed thousands of villagers and many more from the Linlithgow, Bo’ ness, Bridgend and Maddiston areas for decades.

Its workforce has dwindled dangerously after changing ownership several times in recent years after a long period of stability under the GR Stein banner Now the works officially close today and electrician, Robert McMeechan has the unenviable task of shutting down the works where he has been employed since he was 16 years old

There has only been a skeleton staff working in recent weeks with hundreds departing over the past few months most of them knowing no other work than what they did at the brickworks plant.”

Said local amateur historian Murdoch Kennedy this week: “I was reminded of the words of the late George Charleston in a poem about the closure of another local employer Lochmill when he wrote:

The latest local victim of, the economic knife was to them, not just a workplace but, far more, a way of life

Added Murdoch: “I have no doubt however that the sadness of Steins final closure will provoke many memories of happier times “

Mr Kennedy also recalled a tribute in verse about Manuel Brickworks penned by the late David Patterson of Linlithgow Bridge

who died in 1977, it was entitled.

“Jock Baillie’s Heavy Squad”

Big Jimmy said; Unload yer bricks

And mak yer wey tae Number Six

Jock Bailie’s breaking up the road

He needs yer lorry to take the load

Big Jock’s squad they worked like deils

Wi picks an shovels and pneumatic dreels

When the digging-oot is aw complete

They’ll fill it up wi good concrete

Tam Robertson and Jock McNee

Can dae a job like onie three

Wi’ oilskin coats and troosers tae

In lashin’ rain they worked aw day

A’ at their side worked Jimmy Hume

A wiry lad frae Lithgy toun

An’ frae Brigend wha’ did they send

But stocky, hardy Paddy Muldoon

Jock Baillie telt me tae be wary

Because the road is awfie nairy

Roughriders, forklifts, lorries tae

Are passin by here aw the day

Wee Paddy wi’ his rheumatic pains

Wis sent tae clear the chokit drains

He’s pokin here and pokin there

Wi watter runnin everywhere

Tae set the job aw in line

Alan Steele is daein fine

He’s goat the pins and lines tae fix

Aw ready for the concrete mix

He’ll dump doon every concrete load

Tae mak an even, level road

For heavy traffic every day

A tradesman job yeve goat tae hae

JockBaillie’s goat a heavy squad

Among his workers, no a fraud

As honest as the day is long

They’ll work until the whistle’s gone

Big Jock’s happy as onie Lord

Tae be in chairge o’ sic a squad

Says he: “Ah’ve nae Tam, Dick an Harry

Ah’ll settle for Tam, Jock and Paddy”

Below – Two, small special shapes found on site. They are unstamped.

Below – A small cube measuring approximately 1½” on all sides and stamped 769 which was found on site. This was possible a test sample of brick to be analysed in the laboratory.

Below – Found by Ian Suddaby on site. This cut brick has been marked ‘Lab’ and was no doubt a test sample examined in the laboratory.

Below – A small unstamped ‘special’ which was found on site. It is perhaps a piece of kiln furniture.

.

Below – An undated photo of the Manuel Works. It depicts the East Mill Shed. Source – Facebook – “GR Stein’s brickwork Whitecross reunion page’

Colin Boyle states – Just past the yellow GR Stein sign at the foot of the mine brae, there was a door to a wee, I think at one point, a paint shop.

It was empty when I started there and it was in need of new lighting and power so me and John McGill got to bend some conduit and pull in some single cores.

It became a howf for Billy Meeks. And on a Friday afternoon, I got my apprentice log book done in jig time so I could rush over there for some “intellectual chit chat” with other like-minded fellows

Below – A close-up of Archie Breen’s paint shop.