Alternative brickworks include:

- West Works, Armadale, West Lothian.

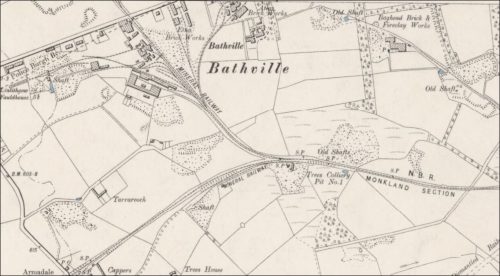

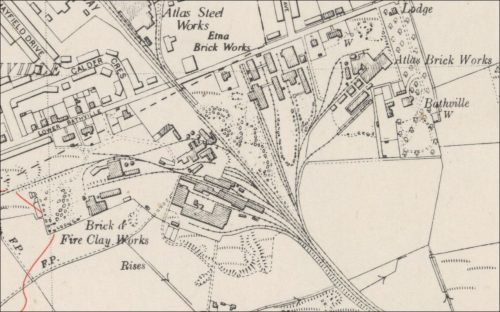

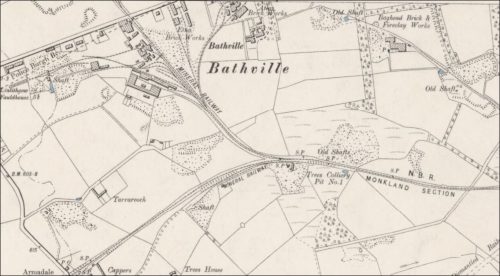

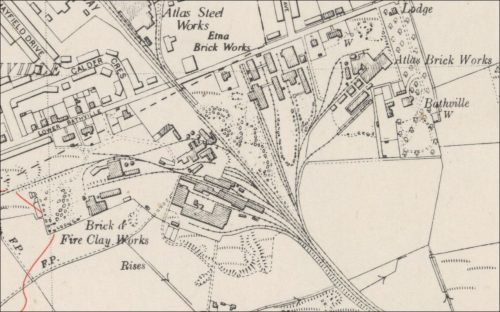

Canmore – The works are situated between Bathville Pipe Works and Atlas Brickworks (NS96NW 38). The Ordnance Survey Map (OS 25-inch, Linlithgowshire, sheet ?NX.I) showed two 10 chamber Hoffman Kilns which were also shown on the map of 1897 … The westernmost kiln was still standing in 1978 but out of use …

A Newcastle Kiln to the east of the works in 1917 was demolished after 1956 … A loading conveyor and works changing room replaced it. At the south of the works, a 16-chamber Hoffman (built c.1898) was standing but out of use in 1978, and another continuous kiln, west of this, was demolished before 1956. The works had had many alterations after 1956; a stable was demolished and the drying and moulding shop which had stood between one of the Hoffman [kilns] and the Newcastle [kiln] has also been demolished. The machine, screen and mill house at the west side of the works were still used as the machine wing in 1978, but the building was probably different … There were tramways throughout the works in 1917, and still in the 1940s … but a wagon tippler situated south of the crusher house (still in use in 1978) had been demolished, and the pan mill and moulding shop (situated between the two south kilns) likewise had been demolished after 1956. In1978 the works had 4 Hoffman-type chamber kilns. The newest, which stood parallel to the 26 chamber kiln, had been built to a traditional continuous design in 1964. The kiln had been converted in 1975 to allow it to be set by forklift trucks, as opposed to the traditional system of bogies carrying 167 unfired [green] bricks) drawn by Lister tractors. The bogies took the bricks from the press to the wicket doors, and the kilns were set by hand. After firing the bricks were again hand loaded onto the bogies and sent to the central loading unit.

Doors the same size as the chamber arch were opened up at each end of the new kiln. Brick packs were formed in the machine wing and transported by forklift truck through the large end doors, the kiln sections being set in four-packs; two on the bottom and two on top. When the kiln was unloaded after firing, the forklift trucks lifted a bottom and a top pack at the same time (a load of 4.5 tons). It was estimated that this conversion doubled the output of the kiln; whereas previously the kiln burnt 18 chambers per week at 12 500 bricks per chamber, in 1976 it was claimed that it consistently did a full round equivalent to 28 chambers, with 16 500 bricks per chamber. The doors, in effect, turned a 28 chamber kiln into one operated on a quarter-kiln setting and drawing cycle.

In 1978, the machine wing was situated south of the 10 chamber kilns, and west of the other two. It contained … five Mitchell double brick presses and three pan mills. The only Bradley and Craven machinery which had been supplied to Etna Works were a double shafted and a single shafted tandem mixer (No. 3224) which was supplied in 1954 and of which there are photographs taken by the company in the 1960s (see MS/500/57/8). And a 16 inch, non-de-aired, Auger Machine (No. 2712) which was supplied in 1946.

The works were established in the late 19th century at Armadale to work the highly refractory aluminous fireclays of the Millstone Grit series in the area and their products had, by the early 1960s, a firmly established market over a wide field at home and overseas in all the major industrial where refractories were required.

The “ETNA” brand made by UFP Ltd in the 1960s was particularly suitable for carbonizing plants, cement kilns, coke ovens, cupolas, lime kilns, mill furnaces, pottery kilns, water tube boilers…

This brand was also made at the West Works which were built in mid-1960 to take over the refractory production once carried on at both the Etna and Atlas Works.

The making of firebricks probably ceased in the 1960s sometime after the alterations mentioned above and in 1978 only composition bricks marked “UFP” were being produced.

Since 1978, the easternmost 10 chambered kiln had been converted to be set and loaded by fork-lift truck and was in use in 1981, and the area between the two 10 chamber kilns had been covered.

Scotland Places

Info – Brickmaking in Armadale.

1892 – 1893 – Jas Wood, Etna Brickworks, Bathville, Armadale Station, Linlithgowshire; office, 28 Royal Exchange Square.

1893 – 1894 – Jas Wood, Etna and Atlas Brickworks, Bathville, Armadale Station, Linlithgowshire; office, 28 Royal Exchange Square.

Below – 1896 – Etna Brickworks.

1896 – James Wood, Armadale, Linlithgow, Head Office, 28 Royal Exchange Square, Glasgow.

07/11/1896 – Airdrie and Coatbridge Advertiser – Glasgow Royal Infirmary – Contributors include Jas Wood Limited Etna and Atlas Brickworks, Bathville – £3 15s.

19/12/1896 – Linlithgowshire Gazette – Accident at Bathville – On Monday morning a boy named James Fisher, employed at the Etna Brickwork, belonging to Mr Wood, in some way got his foot entangled between the plates and the side plate of the travelling scree. He was dragged along for two or three yards before the machinery could be stopped. When released his foot was found to be severely lacerated. After being attended to at the work, he was, however, able to proceed to his home.

21/12/1897 – Edinburgh Evening News – Bricklayers wanted – Etna Brickworks, Bathville, Bathgate.

22/01/1898 – Edinburgh Evening News – Bricklayers wanted – Etna Brickworks, Bathville by Bathgate.

16/02/1898 – Glasgow Herald – Bricklayers wanted at Etna Brickworks, Armadale.

21/05/1898 – Linlithgowshire Gazette – A young thief. A young lad named James Cowley, in custody, pleaded guilty having, on 7th May, stolen 18s 9d from a pitcher belonging to Bridget McCumisky, brickfield worker, Bathgate, which she had left temporarily at the brick kiln at Etna Brickworks, Bathgate, occupied by James Wood, brick manufacturer. Accused was up before the Sheriff on 9th May, and pleaded guilty, but the Sheriff, in respect of the youth of the accused, declined to receive a plea until his parents or guardian were present. The Fiscal stated that he had spent the money on footballs, and had only shilling left. The Sheriff, in sentencing him to receive stripes with the birch rod, said that the case had been adjourned from Monday till Wednesday to permit of his father being present, as he did not know anything about the charge. His father took him to the Court gate, but he there ran off and his father was so much distressed at this that he got drunk and had to be locked up.

24/09/1898 – West Lothian Courier – Three labourers wanted at Etna Brickworks Armadale. Constant work to steady men. Apply to the foreman at the works.

10/11/1898 – Edinburgh Evening News – Mysterious disappearance of an Armadale man. Wm. Brown, widower, employed as a kiln burner at the Etna Brickworks, Bathville, has been missing since Saturday. His wife died about six months ago, and the youngest child has been under the care of an aunt at Bellshill, to which place the father was in the habit of journeying for the purpose of visiting his child. On Saturday afternoon, having paid his usual visit, he was seen by his friends to enter the train for Coatbridge on his journey home. Since then no tidings had been heard him, although a search had been made for him. It is feared that he had taken the wrong side of the line when changing from the Central to Sunnyside Station, and fallen into the canal.

Below – 24/12/1898 – Linlithgowshire Gazette – Theft – not guilty. Reference to the No 4 kiln.

20/01/1900 – West Lothian Courier – Armadale. Brickwork Accident. On Monday morning at 9 o’clock Peter Nimmo, a young lad between 13 and 14 years of age residing with his uncle, Mr John Nimmo in East Main St., met with an accident at the Etna Brickwork. when his right forearm was fractured. The lad was engaged on the high loft, attending to the ground clay lift, when the breakfast horn blew; and on making his way down he missed his foot, and fell a short distance. In addition to a simple fracture at the wrist, he was slightly injured on the right leg.

Below – 05/05/1900 – Glasgow Herald – Foreman wanted for Etna Brickworks, Armadale. Must have experience in Hoffman Kilns and brickwork machinery. Apply by letter stating experience and wages wanted to James Wood, 28 Royal Exchange Square, Glasgow.

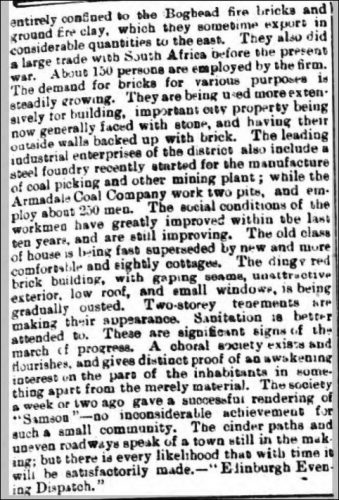

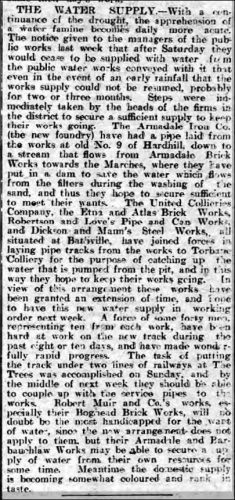

19/05/1900 – West Lothian Courier – Armadale threatened with a water famine … The Etna brickworks suffered to the extent of having to cease the night shift. If the supply is to continue during the summer. consumers will have to be very economical in the use of water.

02/06/1900 – West Lothian Courier – Linlithgow Sheriff Court. Sheriff Macleod. Mary O’Rourke or Margaret Thomson, brickworker, Cochrane McGinnes, Catherine Harkins, Ann McAndrew or Harkins and Margaret Fallow, brickworkers, all residing at 49 Livery Street, Bathgate were charged with on the 18th May at Etna Brickworks, Armadale assaulted Margaret Thomson, brickworker, Cochrane Street, Bathgate by (1) seizing violent hold of her, dragging her about, beating her with the fists and threatening to murder her and (2) behaved in a disorderly manner. They pleaded not guilty but were convicted on evidence. Mary O’Rourke or McGinnes was bound over in 10s 6d, Cathrane Harkins 7s 6d and Ann McAndrew or Harkins and Margaret Tallow in 5s 6d each, to keep the peace for 3 months. (Note – SBH – Making sense of the names is rather confusing in this article!)

10/08/1900 – West Lothian Courier – Few labourers wanted at Etna Brickworks, Armadale.

03/08/1900 – West Lothian Courier – Etna brick workers demand higher wages. The workers at the above works made a demand to the master for higher wages this week and refused to work on Thursday, in order to show that they were in earnest. We understand that the demand is for an increase of 2s per week on the men’s wages and 1s per week on girls’ wages

05/10/1900 – Linlithgowshire Gazette – Accident. James Bradley, aged 13, residing with his parents at Northrigg, met with an accident while engaged at the Etna Brickworks, belonging to James Wood & Co, Ltd., on Saturday. It appears that he was engaged in chapping the sieve to allow the clay to run down into the box where it is mixed when the shirt sleeve on his right arm got into the teeth of the pinion wheel. Fortunately, the driving belt of that part of the machinery was not tight, and when he was drawn in the belt slipped off, but not before his arm had been injured. But for the belt coming off, there can be no doubt that the accident would have been very serious. The lad was attended to by Dr Anderson.

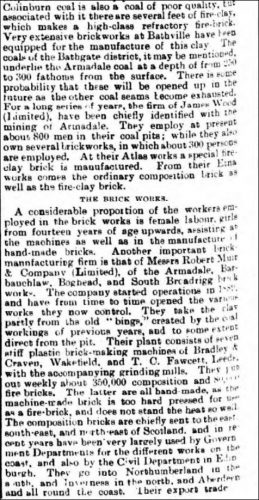

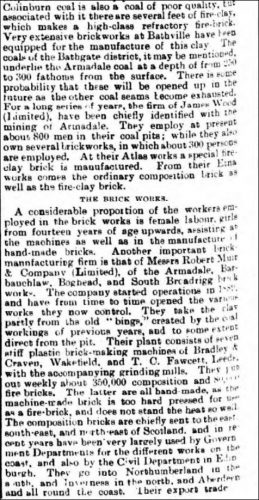

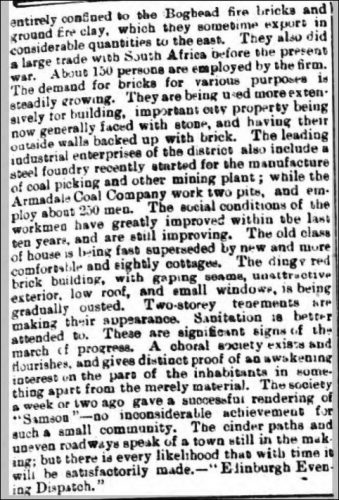

Below – 26/10/1900 – Linlithgowshire Gazette – A history of brickworks in the Bathgate, West Lothian area. One of the most important of our local industries is that of brick making. Quite a number of works, some of them of considerable dimensions, are devoted to this branch of trade, and it would astonish our readers were they told of the vast quantity of bricks which weekly leave this district. That the industry is flourishing in a most remarkable degree is evidenced by the many extensions carried through at most of our local brickworks in recent years and certainly, within the last ten years, the progress made has been enormous. There have been one or two local factors that have lent themselves this increase. There is, for instance, an abundance of clay of a suitable character; then the presence of so many collieries the district makes this a particularly good field for brick making; and not the least of the factors which have contributed to the success of the industry has been the enterprise displayed by the various firms which devote themselves to this class of business. Brick making appliances play so large a part the manufacture of bricks that, in comparison to the large output of material, the number of hands employed is small, yet when we take into account the number and the extent of the brickworks in this neighbourhood, and the very large business which is done, the number of workers, male and female, engaged in this particular branch of trade run into many hundreds. The oldest brickwork in the district is that owned by Messrs Robertson, Love, and Co., it having been in existence for nearly 30 years. Robert Muir and Co. had also an old brickwork before they started their present one. Boghead Brickworks were erected by Mr Gillies of Boghead, and the works were originally used in the manufacture of fire brick and ground fireclay. Years ago the business changed hands, Mr Gillies parting with it to the Boghead Fireclay Company. It was then a small concern, but to meet the growing demands of trade this firm were obliged to considerably enlarge it. They afterwards sold the works to Messrs Dickson and Mann, who a few years later disposed of it to the present proprietors, Messrs Muir and Co. As the demand for the bricks produced in the works continued to grow, a further large addition had to be made, and yet another is in progress. The enterprising firm of Messrs Muir and Co. are, we learn, also making preparations for turning out at these works composition bricks, in addition to those classes bricks presently produced. The works at Bathville owned by James Wood and Co., are of vast dimensions and are divided into two portions, the Atlas and the Etna Brickworks. The Atlas Works are entirely devoted to the manufacture of firebricks, while at the Etna Works composition bricks are produced. An idea will be had of the extent of these works when it is stated that they cover nearly twenty acres of land. In the Etna Works, some 100 hands are employed, while at the Atlas Works there are about 50 workers. At both works, the firm could employ many more hands, but at present, when the trade is so busy, brick workers are not to be got. The Atlas Brickwork is the older of the two. It was begun in a small way a good many years ago by Mr Robert Fleming of Coatbridge, who had as a partner Mr Kopel Moritz. The latter subsequently dropped out of the partnership and removed to the Armadale Brickworks. He continued to be associated with those works till his death, after which the works wore acquired by Mr W. D Samuel and Mr Robert Muir, the present managing directors and original partners of Robert Muir and Co., Ltd., who own Armadale, Barbauchlaw and Boghead Brickworks, and whose fireclay and firebrick products are exported in large quantities to Singapore, Rangoon, Durban, Delagoa Bay, etc. Mr Fleming carried on the Atlas Works himself for some years after the dissolution of his partnership and on his death, the business was acquired from his trustees by Mr Wood of Bathville. Mr Wood threw into the concern considerable enterprise and business ability. He considerably developed the trade and not only made extensive enlargements at the Atlas Works but on his adjoining ground, he erected the Etna Works. Both works are fitted with the latest machinery and improved appliances for the manufacture of all kinds of bricks, and a very large and rapidly growing business is done by the firm. James Wood, Ltd., have their two works fully employed, so far as labour is to be had, in the production bricks alike for the home and export trade. It would be divulging what the firm might regard as a trade secret were we to state the average weight of the bricks which weekly leave their works. It is enough to say that weekly production is enormous and that it is continually increasing. The firm’s products find their way into almost all parts of the world. The firm have good agencies and a splendid connection abroad, and firebricks and ground fireclay are largely exported to Bombay, Calcutta, and elsewhere. As illustrating the advancement made in the method of brick making, it may be mentioned that the kilns now used for the manufacture of composition bricks are those of the continuous Hoffman principle, whereby immense heat is transferred from one chamber to another, and an immense saving of coal is ensured. In the older brickworks in the district, the Newcastle kilns are still in operation for making firebricks. With these kilns, makers have to make their bricks and dry them in a shed with whatever heat they can get. If steam is employed, it is let underneath the kilns by flues, and the heated air dries the bricks. Under the new Hoffman kiln system, however, the bricks are simply taken from the machine and put into the kilns and the hot air follows gradually around. After the brick chamber is emptied it is immediately filled with fresh or green bricks and the heated air from the burning chambers is conducted round in flues underneath the floor of the kilns. By the new method, the bricks are of course quicker and better made. The fireclay comes from the pits in ‘trips’ and the workmen empty it on to a travelling table and hence into a grinding mill. The clay is then lifted from the pit under the grinding mill by elevators up to the sifting loft. Then it goes through sieves, travels down a shoot to the mixer, where there is a constant stream of water flowing and where by means of knives attached to the machine the clay is mixed and pressed into the brick making machine. The clay comes from this machine as a perfect brick. Thereafter the bricks are placed in the Hoffman kiln and in 14 days time they have taken the form of the first-class commercial article ready for market. It will be seen what a revolution this improved method of brick making must have wrought in the brick making trade when it is mentioned that under the old system in good weather, 14 days were required to dry the hand made brick, while 14 more days were occupied in the burning of it. At present an addition consisting of a large drying shed of considerable dimensions is being made to the Etna Works and this addition, when completed, will permit of a greater output of material and lead to the employment of additional hands. The works are managed by Mr Findlay who succeeded the late manager, Mr Hugh Dunlop, who had been connected with the works from the start and who died a few months ago. We can only mention the other brickworks in the district. That belonging to Robertson Love and Co is prospering like others. Mr John Nimmo and Sons have done a fair business at their works while the Armadale Coal Company have kilns in the course of construction for a large new brickwork. The possibilities of the brick-making trade of our district are very great. Situated as Bathgate is almost equidistant between our 2 great commercial cities, Edinburgh and Glasgow, and on the mainline of the railway, there is every certainty that this industry has a bright future. Its growth has been rapid but it is only still in its infancy. When the present factors which are tending to so greatly to depress the building trade have been removed and when the money market is such that it will permit the speculative builder to build as before, the trade will come away with an almost unprecedented boom and much of the new business will naturally come to this district. It is therefore not to be wondered at that some firms are, in anticipation of this demand, enlarging their works and further additions may be anticipated. From a calculation made by a gentleman immediately associated with the trade, some 120,000 composition bricks leave the brickworks in this district daily.

23/11/1900 – West Lothian Courier – Charge of fraud against a girl. Mary Doran, brickworker, daughter of and residing with Michael Doran, miner, Old Town, Bathgate was charged with having on 27th October at the pay office at Etna Brickworks, Bathville pretended to Alexander Norrie, cashier, that she had been sent by Wm. Horsburgh, labourer, employed at said brickworks for his week’s wages, then payable, and thus induced the said Alex. Norrie to hand her the said wages amounting to £1 3s 10d which she then and there received and appropriated to her own use. She pleaded guilty and was dismissed with an admonition.

28/12/1900 – Linlithgowshire Gazette – At the brickworks. So far as the trade at the brickworks is concerned, no complaint can be made with regard to orders. Employment has been regularly found for all hands, and trade has been very brisk all the year-round. At Messrs Robertson, Love, and Co.’s, however, there is a good stock in hand, but it is expected that the orders during the coming year will be such as to readily dispose of this stock. the Etna Brickworks, belonging to Messers James Wood, Limited, some good orders have been secured, including a contract for the brick work for the fortifications at present being built on Dalmeny Estate at South Queensferry. Government work has also been secured by Messrs Robert Muir and Company, who have been successful in a contract for supplying brick for the fortifications being erected on Inch Garvie and on the ground recently purchased from the Dunfermline Guildry at North Queensferry. Despite the high price for some qualities of bricks, the local manufacturers have done very well during the year, and are confident of securing some good orders in the coming year.

12/04/1901 – Linlithgowshire Gazette – Accident at Etna Brickworks – About seven o’clock on Tuesday night, while Edward Walker, Engineman, High Street, Bathgate, was attending to a brickmaking machine at Etna Brickworks, occupied and owned by Messrs Jas. Wood, Ltd., his right hand got caught between the press and spring box of the machine, whereby the three first fingers were severely crushed and lacerated. He was immediately removed to the Royal Infirmary, Edinburgh and we understand that amputation of the three fingers was considered necessary.

03/05/1901 – West Lothian Courier – Fatal accident of steeplejack. On Monday evening, about five o’clock, while James Harvey (44) a steeplejack, residing at Ann Street, Bridgeton, Glasgow, was engaged adding to a smoke stalk, at the Etna Brickworks. Bathville, he fell from the top, a distance of 119 feet, and was killed on the spot. It appears that the deceased had asked his assistant for a particular brick and when he was getting the brick, he heard a piercing cry and saw Harvey fall to the ground. The body landed on the toolbox, which was meshed into splinters. It appears that in making a clutch at the chimney top to save himself, he took a brick away with him. It is said that he took a fit a short time ago and it is not improbable that he may have been affected in this way when he fell. There were working along with him, the contractor, Mr James Robb and Mr Wm. Watson, Glasgow. Deceased leaves a widow, but no children.

26/07/1901 – Linlithgowshire Gazette – On Monday forenoon, while a young man, named George Paddel, residing in Academy Street, was engaged in the vicinity of Etna Brickwork coupling waggons, he let the pole fall and his hand slipped between the buffers two waggons end was severely injured. He was assisted to his lodgings and was attended to by Dr Anderson, who found that the right hand was broken … the pits and brickworks in the district generally resumed full time on Monday after having had the usual holidays during which many had taken advantage of visiting friends, places of interest and the exhibition …

22/01/1902 – The Scotsman (Note – SBH – I am uncertain which Armadale brickworks this article refers to but I have included it here so that it does not go unmissed!) – For sale belonging to the Executry Estate of the late Mr Marshall, Contractor. Portable engine at no 9 pit, Armadale, Bricks large quantity, Fireclay pipes large quantity and various sizes, Whinstone sets and couplings, freestone jambs, Pan Mill at New Brickwork, Armadale, Bricks (40,000 already cleaned at No 8 Pit, Freestone large quantity not including iron. The articles will be shown to enquirers Mr David Sclater, Clerk of Works, Uphall.

14/02/1902 – West Lothian Courier – Reference to Mr Joseph Clayton as manager of the Etna Brickworks.

Below – 21/03/1902 – Linlithgowshire Gazette – An article discusses the Boghead, Bathville, Etna and Atlas Brickworks of West Lothian.

.

06/06/1902 – Linlithgowshire Gazette – Wanted – Contractor for Hoffman Kiln – Apply Foreman, Etna Brickworks, Armadale.

11/06/1902 – Kirkintilloch Herald – Proposed Scottish coal combine – So far as evidence goes (writes a mining correspondent) the rumour of a Scottish Coal Combination is not without foundation. Representatives interested in such a trust are systematically visiting, for valuation purposes, the collieries of those firms who might be disposed to consider the formation of such an amalgamation. Combine visited the collieries of Messrs Jas. Wood, Ltd., in Armadale district. The pits owned by this firm in Armadale district, of which a valuation was taken, together with the siding accommodation belonging to the firm, are as follows;—No. 2 and No. 7 Northrigg, Nos. 2, 5, and 8 Polkemmot, and No. 4 Hartrigg and Colinshiels Pit, while they own Drumpellier Pit, Coatbridge; Meiklehill, Kirkintilloch: and Neilston, Kilsyth. The firm also owns Atlas and Etna Brickworks, which have a large output.

01/07/1902 – Dundee Evening Telegraph – The Scottish Coal Combine – Today the various collieries and brickworks belonging to Messrs James Wood Limited and the collieries belonging to the Armadale Coal Company will be formally handed over to the syndicate known as the Scottish Coal Combination. Yesterday representatives from the Glasgow office of the Combination for stock-taking purposes made a survey of the whole material on hand, furnishings and coal etc, exclusive of the working colliery plant at the different collieries, along with the coal foremen. Messrs James Wood Limited own the following collieries in Armadale district: No 2, No 8, No 6 pits, Polkemmet, No 4 Hartrigg, Nos 2 and 7 Northrigg and Colinshills and also the well known Atlas and Etna Brickworks. They further own Drumpelier Colliery, Coatbridge, Meiklehill, Kirkintilloch, and Neilston Colliery Kilsyth. They employ over a thousand men in Armadale district. The Armadale Coal Company own the 2 pits Nos 17 and 23 Buttness.

14/11/1902 – West Lothian Courier – Crushed Between Two Waggons. John Brown, residing in the Old Town, Bathgate, met with a serious accident at the Etna Brickworks, Bathville, yesterday morning, when he was caught between two waggons while shunting and severely crushed. Medical aid was procured at once when it was found expedient to have him removed to the Royal Infirmary, Edinburgh, but it is feared he will not be able to survive his injury. Very little is known of Brown amongst the workers, many only knowing him by the appellation of “Sydney.”

11/04/1904 – Edinburgh Evening News – Reference to storm damage at Etna Brickworks, the property of the United Collieries Limited. (See entry dated 15/04/1904 for more detail)

Below – 15/04/1904 – Linlithgowshire Gazette – Brickwork smoke stalk destroyed by lightning. Saturday was a day of blizzards that raged all day, cold, hail, and snow storms following each other in rapid succession. In the afternoon at about 4 o’clock, the sky became darker than usual and lights had to be lit in places of business to carry on the work. The wind was raging furiously when a slight flash of lightning was noticed followed by a distant peal of thunder. At ten minutes to four, a more vivid flash lit up the whole place for a second and then there followed a deafening peal of thunder which frightened horses and sent those out of doors to seek shelter. Shortly afterwards it was learned that the lightning had struck No. 4 smoke stalk of the Etna brickworks, and had rent it from top to bottom, knocking away 30 feet from the top and leaving a large part of it in a very ragged condition. Fortunately, the works had closed for the day, otherwise, lives must have been lost, as the spot where the most of bricks fell from the top of the chimney, which was 120 feet high, was swarming with workmen and women before day’s work closed. The storm was still raging on Sunday morning, when, between 10 and 11 o’clock, the wind was so strong to blow over about another 30 feet of the stalk, leaving only about the half standing. The lightning seems to have struck the top of the chimney and ran down the west outside, stripping two or three courses of bricks on its track. The great wonder is that the other chimneys, which are placed thickly around the one struck, escaped. The falling bricks caused considerable damage to the shed roof and boiler top but the damage done was much less than might have been expected. Two firemen engaged to fire the kilns were in one of the sheds near hand, sheltering themselves at the time, and were quite unaware of what had happened until they appeared outside. The wreck has caused, for a time, the double shifting of the other part of the work until the repairs are effected.

15/04/1904 – Linlithgowshire Gazette – What might be reckoned as a narrow escape from lightning on Saturday afternoon was experienced by Mr John Wallace, foreman carrier from Armadale Railway Station. He was at his horse’s head between the station and Bathville when the flash of lightning that struck the chimney stalk of the Etna Brickworks glanced off the collar hems and singed his horse’s mane. The polished steel hem on the near side was made quite black, and will not now polish.

06/05/1904 – Linlithgowshire Gazette – The smoke stalk at Etna Brickworks, which was struck by lightning on Saturday, 9th April, is now being re-built. Mr Topping, builder, Whitburn, has been entrusted with the contract and has had the ragged part of the chimney taken down, leaving a stump of about 50 feet upon which to build, after the displaced course outside bricks which forms rut on the west side have been replaced.

11/11/1904 – Linlithgowshire Gazette – Accident at Etna Brickworks – Yesterday morning an unfortunate accident happened to a young man, named Peter Creamar, a brick worker, residing at Thomson’s Land, by which he had an arm broken. Having had occasion to pass between two stacks of bricks, where a large crown wheel was standing perpendicular, the passage being rather narrow, Creamar was unable to pass without pressing on the wheel, which caused the wheel to fall over him, with the above result.

1905 – Operated by United Collieries Ltd.

24/11/1905 – West Lothian Courier – Mr Driscoll, Bathville met with an accident while employed at his work at the Etna Brickworks, Armadale owned by the United Colliery Company on Saturday. It appears that Mr Driscoll had been engaged at the stamp press when something prevented the spring from rising and on putting in his hand to remove the obstruction the spring suddenly came up with great speed with the result that his hand was caught between the spring and the stamp press. On being released from his precarious position it was found that his right hand had been badly injured and on medical aid being summoned it was found advisable to have him removed to the Edinburgh Royal Infirmary. On his arrival there, however, it was observed that the injuries sustained were not of such a serious nature as was at first anticipated and that in all probability the hand, which at first was thought would require to be amputated, will be saved.

04/12/1906 – Edinburgh Evening News – About midnight last night fire broke out in a stackyard adjoining Etna Brickworks, near Armadale, owned by the United Collieries (Limited). There were in the yard 10 stacks of hay. The high wind prevailing the time soon fanned the blaze to furnace heat, and although there were many people present nothing could be done to save the hay and the stacks were reduced to ashes.

13/12/1907 – West Lothian Courier – Workmen’s compensation case. Sheriff Macleod has given his decision in Linlithgow Sheriff Court in an application at the instance of the United Collieries, Limited, to have the compensation paid by them to Patrick O’Driscoll, brick worker, Armadale stopped or diminished in connection with an accident which happened to him at Etna Brickworks, Armadale, on 19th October 1905, when the defender, who was engaged as a mixer in the brickworks sustained an injury to his right hand which necessitated the amputation of two fingers. Compensation had been paid by the Company at the rate of 8s per week and they averred that O’Driscoll was now and had been for sometime fit for work. O’Driscoll, in his answer, pleaded that he was still unable to work. The Sheriff, after considering the evidence, has reduced the compensation to 4s per week.

28/02/1908 – West Lothian Courier – Accident at Etna Brickworks. On Friday David Smith, South Street, Armadale, while at work in Etna Brickworks fell from a gangway and in falling sustained injuries to his head, while his legs were crushed by a barrel containing cement rolling upon him. The young man was in the act of assisting rolling up the barrel of cement when the accident occurred. He was able to go to works after a few days rest but he still complains of pains in his head and legs.

1/7/07/1908 – Linlithgowshire Gazette – Saturday was a fatal day for of the ponies engaged to draw hutches of fireclay from No. 4 of Bathville bing to the railway siding at Etna Brickworks. The pony slipped its foot when on the scaffold, fell over, and broke a leg. The knacker did the rest.

also

The holidays started at Dickson and Manns works on Wednesday and will continue till Tuesday, 28th. The Etna Brickworks are only to be closed for four days, but the Atlas is to have three weeks, and the collieries will be closed from the 16th to the 27th.

11/12/1908 – Linlithgowshire Gazette – John Wilson, an elderly man engaged at the Etna Brickworks, Bathville, as cashier, failed to turn up on Saturday to pay the workmen, and when inquiries were made it was found that he had disappeared. On Friday he is reported to have sent to the colliery office at Bathville (brickworks belonging to the United Collieries Company) for £130 to pay the workmen on Saturday, this being £40 in excess of the usual amount but not being an unusual thing, the cash was handed over, but the request that no coppers were required caused some comment. On Friday afternoon Wilson found it necessary to go to Glasgow but promised to be home in the evening. He failed to reach home that night, but sent a telegram to Mr John Richmond, the manager of the works, saying had met with an accident but would be home with the first train in the morning. No address was given on the telegram, which was sent from Glasgow. After the second train arrived from Glasgow on Saturday morning, and the missing cashier not having put in an appearance, the suspicion of those interested was aroused, more especially as the cash had run short at the colliery office, and inquiries were being made to see if the brickworks cashier had any spare. Bailie Currie, the foreman blacksmith, was sent for and broke open the safe, to find there were neither books nor money there. Tho police were then sent for, and the cashier’s house, in Station Road, searched, but nothing was found. Mr Wilson, who had held the position of clerk and cashier at the brickworks for the past ten years, was known to be a man of a very retiring’ disposition taking up with no company, and a total abstainer. In dietary he is a strict vegetarian and is a strong believer in Spiritualism. When the police had exhausted their search of the house, no trace of books or money could be found, and no further word coming from the missing clerk to explain his detention it became apparent that the books had been destroyed. It is believed, from traces burnt of paper, that they have been burned. Mr Wilson had been living apart from his wife since August and it is believed that through this his mind has become very much disturbed and that has made up his determination to quit the country on this account. He has left behind him a valuable house of furniture and some highly-priced dogs, one of which is a magnificent type of a great Dane, about eight months old. Up to the time of writing no trace of him, or any clue as to his whereabouts has come hand.

12/02/1909 – Linlithgowshire Gazette – Considerable interest was centred on a quantity of banknotes found by some small boys on Sunday. The boys, three in number, about 10 years of age, while rambling Sunday afternoon, came to the fireclay bing at No. 4 Pit, Bathville, which is at present being removed for use at Etna Brickworks, and entering it they noticed what they thought was a book lying a piece of, wood, but after picking it and examining they found it to be a bunch banknotes …

12/02/1909 – Linlithgowshire Gazette – Sale of absconding clerks furniture. By a warrant of the Sheriff, the household effects of John Wilson, the clerk who absconded with £130 of the United Collieries Company’s money on Friday, the 4th December last, were disposed of by public auction. It will be remembered that Mr Wilson, who was engaged as a clerk at the Etna Brickworks at Bathville owned by the United Company, withdrew £130 on Friday afternoon, the 4th December, to pay the workmen on Saturday, and that he shortly after receiving the money left for Glasgow on pressing business, promising to be back again that night, and that he never returned. On the safe at the office being broken open neither books nor money were found. A warrant was at once made out for his arrest, but up to the present he has not been caught. He had a valuable house of furniture and three dogs, one great Dane, about eight months old, and two black schipperkes said to be of a good pedigree. A few weeks ago a portion of the furniture was sold to pay the half-year’s rent due on his house in Station Road, and on Thursday the balance of the effects were sold at the instance of the United Collieries Company, under the supervision of Mr Robert Wilson, Sheriffs Officer, Mr John Addison, Bathgate, officiating as auctioneer. Notwithstanding the dull state, of trade in the district for some time, there was a large number of people present and fairly good prices were obtained.

02/02/1909 – Linlithgowshire Gazette – Mr John Barr, foreman joiner Bathville Works (Brickworks?), died on Thursday last week at the age of 43 years. Mr Barr came to Bathville about 20 years ago from a Paisley firm to erect the greenhouses at Bathville House after it was rebuilt by Mr Wood and afterwards remained in Mr Wood’s employment as a works joiner. He succeeded to the foremanship on Mr John Richmond taking over the management the Etna Brickworks, and also had charge the house property the works, a position he continued to hold on the works being transferred the United Collieries Company …

27/08/1909 – Linlithgowshire Gazette – Brickworkers excursion. The employees of the Etna and Atlas Brickworks, to be in line width the other works of the district, organised an excursion to Portobello, which took place on Saturday by special trains. The excursion was not so well-patronised by workpeople as was expected, although the works were idle for the day to allow them the privilege, but those that did take part in it spent a very day enjoyable visiting the Marine Gardens, and breathing in the salt sea air, and returned at night full of the spirit of enjoyment.

12/09/1909 – Linlithgowshire Gazette – Etna and Atlas brickworks export to Canada … there is a large order for a million bricks that is being shipped from Etna and Atlas brickworks to Canada that is taking up all the extra wagons. When this order has been discharged more waggons will be had for coal …

Below – 21/10/1910 – Linlithgowshire Gazette – Death of Duncan Richmond former manager of the Atlas and Etna Brickworks, Bathville. He started work at the works around 1885.

Below – 25/08/1911 – Linlithgowshire Gazette – Drought causes local firms to unite in order to construct a pipeline to bring in water – United Collieries, Etna and Atlas brickworks, Robertson and Loves Pipe and Can Works. Robert Muir and Co’s works at Boghead brickworks will be disadvantaged as they will not be connected to this new supply but their Armadale Barbauchlaw Works may be able to secure a supply of water from their own resources.

15/11/1912 – Linlithgowshire Gazette – Bathgate town council meeting – A letter was read from the postmaster asking formal permission to erect a telephone wire from Armadale Post Office to Etna Brickworks which was granted.

Below – 09/10/1914 – Linlithgowshire Gazette – Brickworks slackening down. The effects of the war are now beginning to tell upon the brick workers in the district. At the Etna Brickworks, which have hitherto been kept full pressure all the year-round, it has been found necessary, owing to the difficulty placed in the way of shipping, to curtail the output, and consequently cut down the number of hands employed. Messrs Robertson and Love’s Fireclay Works at Bathville, where drain pipes and chimney tops are the principal product, they are now finding the effects of the war, with the result that one of the works, known as the top work, is about to be closed down for the present. A general slackness in orders is now being felt all over the district, and before many weeks many hands may be out of employment.

12/04/1918 – Linlithgowshire Gazette – Boys leg cut off – John Wardlaw. 15 years of age, son of Mrs McCracken, East Main Street, while working at Etna Brickworks on Saturday, had the misfortune to lose his right leg. He had occasion to pass a card to one of the workmen and to do so, it is reported, that he made to step over the brick making machine when his foot slipped and got into such a position on the turntable that his leg below the knee was completely severed. He was immediately conveyed to Edinburgh Royal Infirmary. On Hogmanay night his step-father, John McCracken, while engaged as a kiln burner at Boghead was so severely burned that he died in the infirmary, and in addition, Mrs McCracken has another boy dangerously ill with meningitis. The greatest sympathy is felt for Mrs McCracken in her affliction.

18/03/1921 – West Lothian Courier – R Muirs and Coy’s new brickworks manager. On Friday last Mr Daniel Watson, who succeeds Mr Gillespie as brickworks manager with Messrs R Muir and Coy, Armadale commenced his studies. Mr Watson is a native of Cleland and figuratively speaking, may be said to have been born into the business. His father was in the same line and it is very interesting to note, was the first manager of the Etna Brickworks, then owned by Mr James Wood of Wallhouse and which are now owned by United Collieries Ltd. His uncle too, is in the same business and he, it is also noteworthy to state, was for a period, manager at Mr King’s Possil Brickwork, Glasgow. Mr Watson entered the brickworks at the early age of 12 years and while yet in his teens was appointed manager of Cambuslang Brickworks. From here he went as the manager to the Linwood Brick Manufacturing Company, Paisley and it is from Paisley that he comes to take over his Armadale managership. Just a little over 40, he looks the ideal manager, and his, very obviously, a great liking for and interest in the work which he has followed now for fully 30 years.

15/04/1921 – Linlithgowshire Gazette – Short time at the foundries. The miners’ lock-out is beginning to take at the other public works in the district, and should it continue for much longer there must soon be a complete cessation of work for want of fuel. At the foundries, the men are on day notices and the biggest foundry “The Atlas”, many men of all classes have been suspended, while so few orders are coming in that the work is on five days a week, and may have to close any day soon. The Etna Brickworks, belonging to the United Collieries Company, Ltd., being better provided with stocks of coal and clay, will be able hold out the longest.

03/06/1921 – Linlithgowshire Gazette – Public works coming to a complete stand – Week after week one public work after another is compelled to shut down for want of fuel. First the Atlas Steel Foundry had to close down, then Messrs R. Muir and Co,’s Brickworks, and next Messrs Robertson and Love’s Fireclay Pipe and Can Morks, and lastly Messrs Dickson and Mann, Ltd., have had to close their steel foundry, and the Etna and Atlas Brickworks, which were well stocked begin with, have now also had to shut down for want of coal. Messrs Dickson and Mann could probably have held out a little longer as far as fuel is concerned, but the opportunity is being taken to make some desirable repairs on the furnace. They are still carrying on their engineering shops, and the United Collieries are able to carry on their machine shops and wagon building shops, being little fuel required with them. All the chimney stacks being now smokeless, the air is pure that one can’t help commenting what a blessing it would be to humanity if the air pollution by smoke could be entirely eliminated. It’s a poor misfortune that does not yield some compensation.

08/07/1921 – Linlithgowshire Gazette – Brickworks re-opening. With the resumption of the miners on Monday, Messrs Muir’s Armadale Brickwork were set in operation again, the first day’s coal being utilised for that purpose. Other works would start immediately but for the fact that the holiday season is on, and if the workers are asked to work during the holiday week they will be able to demand double pay. The Etna and Atlas Brickworks are not to lose much time before they are turning out their full complement of building brick, and the fireclay pipe and chimney can works are in operation again, the demand for their output being enormous. The foundries don’t seem to be in a hurry to get started. At the Atlas Foundry, some dressers have been working lately clearing away some order, and now, in view of the holidays, notice has been posted that the works will close down on Thursday the 7th till Tuesday the 19th.

16/09/1921 – Linlithgowshire Gazette – Peter Tearney, the man who was reported last week to have been found lying unconscious in a kiln at Etna Brickworks and taken to Edinburgh Royal Infirmary, died without regaining consciousness, having been badly burned about the body. It was believed that he belonged to Broxburn, and inquiries were made to try and find if he had any relations there.

Below – 18/08/1922 – Linlithgowshire Gazette – Brickworks going slow. The fact that the Scottish Board of Health have put a ban on bricks at a higher price than 50s a thousand for Government-subsidised housing schemes and that brick manufacturers are not disposed to concede the 5s necessary to bring the price to that figure has brought a slackness in the brickmaking industry in this district. The Etna Brickworks at Bathville belonging to the United Collieries Company Limited, usually kept at full speed, and employing many hands to keep pace with their orders have had to proclaim 5 days a week for their workers until the difference in price is settled. Messrs Muir also had to go slow owing to the new price made by the Board of Health who claim that the bricks can be supplied at the money. Unless a settlement is come to this week, the brickmaking, building and allied trades will be at a standstill and thousands more thrown on to the unemployment list.

18/04/1924 – Linlithgowshire Gazette – Accident at Etna Brickworks. Maggie Coventry (18), residing at Craig Terrace, Blackridge, while workings at the Etna Brickworks, Armadale, last Friday, was injured about the forehead. About 12.30 p.m. she and another girl were transferring bricks. The girl Coventry bent down to lift some bricks just as her partner threw some upwards, with the result that she was hit on the forehead, making a bad gash. She was immediately hurried to the office, where her injury was bandaged, and a taxi was sent for to convey her to her home. Dr Lindsay was sent for and on arrival, he pronounced the injury as nothing serious. The injured girl managed to attend her grandparents’ diamond wedding in the Public Hall the same night.

Below – 1929 – Etna and Atlas Brickworks from the air.

16/10/1931 – Linlithgowshire Gazette – Motor lorry causes damage. Not a little excitement was caused among the residents of Watt Avenue, Bathville Road, Armadale, early last Friday morning. Two heavy lorries belonging Messrs Russell, contractors, West Calder, emerged one from the bottom and the other from the top entrances of the Etna Brickworks and attempted to pass each other. In passing one of the lorries got out of control and careered on to the pathway, and through the iron railing bordering the houses. About 26 feet of the railing was torn down, but luckily no person was injured.

16/10/1931 – Linlithgowshire Gazette – Steeplejack killed – Distressing fatality at Armadale Brickworks – A distressing accident, involving the death of a steeplejack, occurred at the Etna Brickworks. Armadale, on Monday afternoon at about 1.45. The victim, George Robb, 260 Dunn St. Bridgeton, Glasgow, an employee of Messrs Cumming & Company, steeplejacks, Glasgow was repairing the top of one of the works chimneys when some of the masonry gave way, and he was hurled down a distance of 120 feet. He fell on a waggon which was standing in a siding at the foot of the stack and sustained terrible internal injuries. The skull was also fractured, besides extensive facial injuries. He was immediately rushed to Glasgow Royal Infirmary where he died shortly afterwards. The sudden and tragic nature of the unfortunate man’s death caused a gloom over the entire works and left an impression not easily forgotten.

02/12/1931 – Falkirk Herald – West Lothian Industries – Promising Revival in Brickmaking and Hosiery. A promising revival in certain industries in West Lothian is reported notably to the manufacture of bricks and hosiery. One of the busiest places in the country at the moment is the Etna Brick Works, at Armadale, belonging to the United Collieries Ltd. An official stated that there had been a sudden revival of trade, and they were supplying the demand as it occurred. A few weeks ago the daily output of bricks from the works was 25,000, and last week the figure was almost 55,000. Not only has the spurt to the industry been responsible for the employment of additional men, but it has also been found necessary to put on a night shift. A large number of the bricks have been sent to Glasgow for housing achievement. This output of bricks is regarded as a really high for a brickwork in the provisional housing schemes in progress in West Lothian are being supplied. The prospect of the brick trade is promising. At the company’s other brickworks at Bathville, the employees are also busy …

03/06/1932 – West Lothian Courier – Waggon shunting accident. On Monday while engaged checking and ticketing railway waggons at Etna Brickworks, Bathgate, a clerk had a serious misadventure. The unfortunate young man, James Christie, who resides in South Street. Armadale had the thumb and the second finger of his right hand jammed between the inner part of a buffer on a railway waggon and the face of the socket into which the middle part of the buffer goes. The young man’s wounds having been dressed he proceeded home where he was medically attended. It is feared that part of the thumb may be lost, but everything is done to save amputation.

Below – 1938 – Etna Brickworks.

03/10/1941 – West Lothian Courier – The death occurred at his residence, 7 Watt Avenue, Armadale, on Sunday, of Mr W. R. Notman. an Armadale octogenarian. Mr Notman, who came to Armadale from Larkhall, was cashier for a considerable number of years at the Etna Brickworks of the United Collieries, Ltd., and retired some ten or twelve years ago …

17/10/1941 – West Lothian Courier – The United Collieries Ltd., brick manufacturers, Etna Brickworks, Lower Bathville. Armadale were charged at the instance of H.M. Inspector of Factories that, on 6th May a shaft was not securely fenced in consequence of which Richard McKechnie (15), an employee residing at 61 Mayfield Drive, Armadale suffered bodily injury. Mr A. B. Crawford, H.M. Inspector at Factories prosecuting said that the case had been taken under the Factories Act 1937, for a breach of Section 13. A shaft that was situated some 39 feet, above the ground and access to the shaft was obtained by means of a stairway. The shaft projected onto a gangway. Shortly after 7 a.m., an engineer sent the boy to oil the bearing of this revolving shaft and while engaged in the work on the restricted space of the gangway his jacket caught on a side pin of the shaft. He was rather badly bruised but fortunately, his jacket was cut away and he rolled down the gangway. His jacket being afterwards found wrapped around a part of the shaft, which has since been guarded. It was a miracle the boy had not been killed. The Act gave a proviso that the shaft had to be safe by construction if not fenced. In this particular case, access to the shaft was easy and the boy had been doing nothing more or less than he had been expected to do. He asked that the case be looked upon from a serious point of view. In these days when so many inexperienced persons were employed every care should taken to see that they were working under safe conditions. Expenses in the case amounted to 10s. Mr Fyffe, secretary of the company said the firm quite appreciated the seriousness of the matter and the firm were very glad indeed that nothing else happened. The position of manager of the works had been a hereditary one for years and there were no more anxious or careful managers than the managers of these works. They regretted and the company regretted, what had happened. The works had been periodically visited by inspectors who had made certain recommendations which had always been carried out but nothing had ever been said about this shaft. A penalty of £15 was imposed.

01/10/1943 – West Lothian Courier – An outbreak of fire occurred on Tuesday afternoon in the engine house at Etna Brickworks, Hardhill Road, owned by the United Collieries, Ltd. A detachment of the County N.F.B. was summoned and succeeded in preventing the fire from spreading to the adjoining machine shop. Damage estimated at over £200 was done to the floor, roof, doors, and windows of the engine house.

Below – 1944 – 1969 – Etna Brickworks

1947 – Operated by United Fireclay Products Ltd.

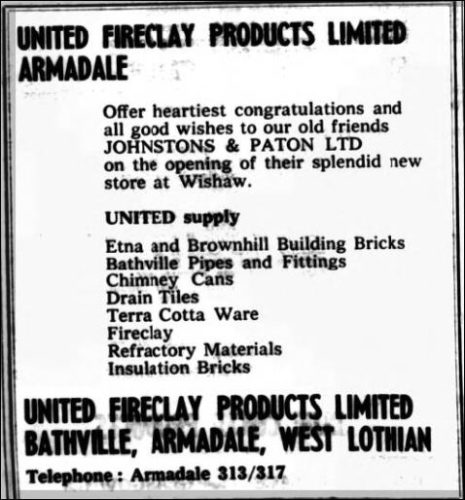

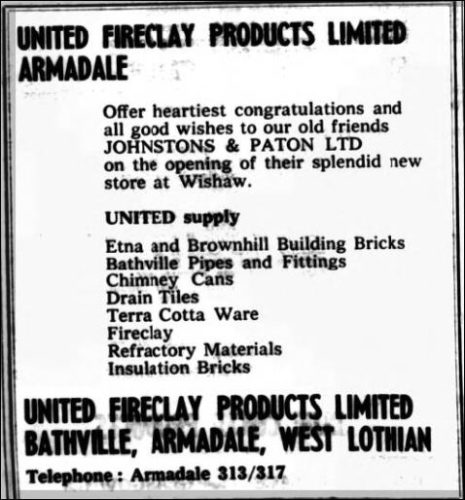

1947 – United Fireclay Products Limited comprised of the Etna and Atlas Firebrick Works, The Bathville Pipe Works, the UNICOL Tileworks, all at Armadale and the Brownhill building brickworks at Clelland, Lanarkshire. Lower demand for refractories led to the Etna Works being converted to making building bricks under the ETNA brand and the closure of the Atlas Works in 1973. Gibbons Dudley took over the United Fireclay Products in 1971 and they were bought over by Steetley Ltd in 1981 who then sold the Etna and Brownhill Works to GISCOL Ltd.

28/03/1947 – West Lothian Courier – Office boy wanted for brickworks office. Apply Etna Brickworks, Armadale.

05/12/1947 – West Lothian Courier – About 200 workers employed in two brickworks in Armadale were involved in an unofficial strike that took place on Wednesday. The works affected are Etna Brickworks, owned by United Collieries Ltd., and Barbauchlaw Brickworks owned by Rose Ltd. It is stated that the workers are claiming an increase of £1 per week and a five-day working week. At a meeting of the strikers held yesterday, it was decided to resume work this morning (Friday). Negotiations with the employers will continue.

22/05/1953 – West Lothian Courier – The death occurred at his home at Station Road, Armadale, last Saturday, of one of the best known and oldest residents in the Burgh. He was Mr John Richmond, aged 92, former manager of Atlas and Etna Brickworks. Armadale. Mr Richmond, who was a native of Braeside, Ballieston, had resided in Armadale for more than 60 years. An expert at his job, he was well-known in the trade throughout Scotland and enjoyed the confidence of employers and employees alike. During his period as manager, he was in no small measure responsible for the high prestige established by Atlas and Etna products in the building trade. He retired many years ago but continued to enjoy good health and remained active until two months before his death. Predeceased by his wife a number of years ago, Mr Richmond is survived by his family of three daughters and two sons. One of the sons, Mr John Richmond, succeeded his father as manager at Atas and Etna Brickworks.

15/04/1955 – West Lothian Courier – Accident at brickworks. A young Bathgate man, John Weir, driver’s mate, 7 Birniehill Avenue, Bathgate was injured in an accident at Etna Brickworks, Bathville, last Thursday. Along with other men, he was engaged in letting a trailer down a slope to a loading bank. It is assumed that Weir, who was operating the brake, tripped and fell and the trailer got out of control. He had to lump for his life and although he got partially clear he was crushed between the vehicle and the bank and had to be removed to Bangour Hospital suffering from a broken arm, broken ribs and lacerations.

09/06/1961 – West Lothian Courier – Over a period of two years, two lorry drivers employed by the United Fireclay Products, Ltd., at Etna Brickworks, Bathville, Armadale. systematically stole 61,000 bricks between them. At Linlithgow Sheriff Court on Wednesday the drivers who were charged separately were fined a total of £35. James Devlin McNulty (29), 37 Marches Drive. Armadale. who pleaded guilty to stealing 44,000 building bricks between Ist February 1959 and 25th March 1961, was fined £20 and George Dunn (49), “Caplawhead” Station Road, Armadale, who during the same period admitted stealing 17,000 building bricks, was lined £15. Procurator – Fiscal, Mr P. F. Hamilton, told Sheriff-Substitute Victor D. B. Skae, that the bricks were valued at £6 10s. per thousand but McNulty who had been selling them to anyone willing to buy them would get nothing like that sum for them. The bricks were valued at £286. The serious thing about this case and another which is coming before your Lordship is the breach of trust involved. McNulty who is married with one child and earns £14 per week, told the Sheriff that he knew now he had been rather foolish. Mr Hamilton stated that in the case of Dunn the bricks were similarly valued at £6 10s per thousand, with a total value of £110. Like McNulty, he had been dismissed from his employment but he had been with the firm for 15 years. Dunn stated that formerly he earned a weekly wage of £14 but now earned £12. Imposing a fine of £15. Sheriff Skae told Dunn that he should be thoroughly ashamed with himself having served the firm for 15 years. Both men were allowed one month to pay.

Below – 01/03/1963 – United Fireclay Products Limited advert. Do you like statistics? We don’t very much either but do you know United have produced 1,400,000,000 ETNA Compo Bricks in the 70 years they have been serving West Lothian? This is enough bricks to build a wall 2-ft. high right around the world or to build a house for every person (person, not family) in West Lothian. If your house is not built of sandstone, there is a 10 in 1 chance that it is built with ETNA bricks. Seventy years of service and never a failure. We have manufactured 1,250,000 tons of ATLAS refractories for consumption locally and throughout the world. Their contribution has helped to make Scottish steel (and other metals) the highly respected products they are. ETNA bricks that are built and stay built, UNITED pipes that are laid and stay laid, ATLAS refractories which are safe and sure, are the basis for the faith we have in UNITED FIRECLAY PRODUCTS in West Lothian and in Scotland.

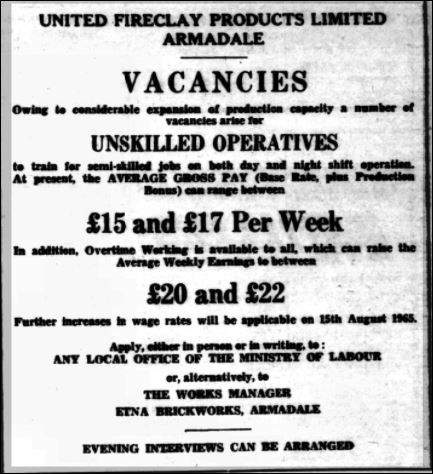

30/10/1964 – West Lothian Courier – Brickworkers warned. Brick workers at the United Fireclay Products Ltd. Etna Brickworks at Bathville, Armadale who staged an unofficial strike last week, are being reemployed by the firm but will be given no second chance if there is any further unconstitutional action. The strike started when night shift workers walked out early on Wednesday morning last week, because of a delay in negotiations over a claim for time and one-third pay for night shift work. Day shift workers came out in sympathy. On Friday, the management issued d dismissal notices in terms of the new Contracts of Employment Act, which stipulates that employees can be sacked for unconstitutional action. It also means that when the men go back to work, they have forfeited their previous service record and must start from scratch. The brick workers decided to call off the strike at a meeting on Sunday and on Monday morning, Mr Phil Gillon, organiser for the Transport and General Workers’ Union, met the management. After reporting the outcome of the meeting to the men, Mr Gillon said: ” The management have exercised their right under the Contracts of Employment Act. in claiming the men dismissed themselves because of unofficial action but they have agreed to take everybody back as soon as possible. The work must be phased until such times as the kiln can be brought back to full production.” Mr Gillon agreed that the delay in negotiating the time and a third pay claim was ” partly ” responsible for the stoppage and added: “The main thing is that the men consider 4d. an hour extra for night shift working is all wrong in 1964 and they want to be brought back into line with other industries.” He also said the negotiations will go on between the union and the Scottish Clay Council. On the question of reinstatement, Mr Gillon said: ” The employers were very adamant on it. They made it very clear that if it happened again, the men would be given their cards and would not be given the opportunity of re-applying for work.” A few of the workers returned on Monday night and others have been taken on again during the week. The build-up to the full working force is slow because it takes some time to get the kiln back to full production.

Below – 20/11/1964 – Wishaw Press United Fireclay Products advert with reference to Bathville pipes and fittings, Etna and Brownhill building bricks.

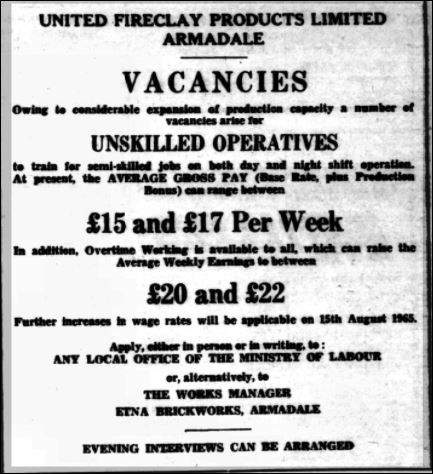

Below – 21/05/1965 – West Lothian Courier – United Fireclay Products Ltd. Owing to considerable expansion of production capacity a number of vacancies arise for unskilled operatives to train for semi-skilled jobs on both day and night shift operation … Works manager, Etna Brickworks, Armadale.

1968 – Etna firebrick production ceased sometime in the mid to late 1960s.

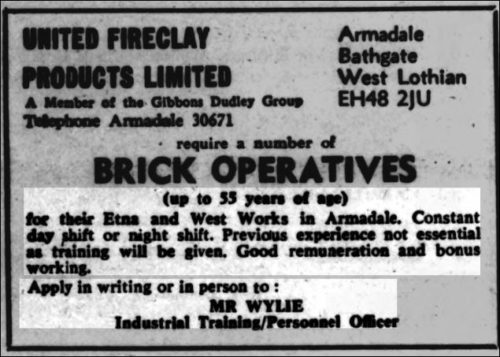

Below – 23/02/1968 – West Lothian Courier – United Fireclay Products Limited advert for the Etna Brickworks.

27/06/1969 to 15/05/1970 (numerous adverts) – West Lothian Courier – United Fireclay Products Ltd, Bathville, Armadale, West Lothian. Telegrams ‘combined’ Armadale. Telephone Armadale 671. Require the following: Kiln drawers, kiln setters, brick machine men, mixers, lifters off and general hands. Previous experience is not essential as training will be given. New improved wage scales and night shift allowances in operation giving opportunity for high earnings and advancement within the grades. Overtime working available. Apply either in person or by telephone to the Personnel Officer, Etna Office, Bathville, Armadale.

1971 – United Fireclay Products Limited merged with Gibbons Dudley Ltd.

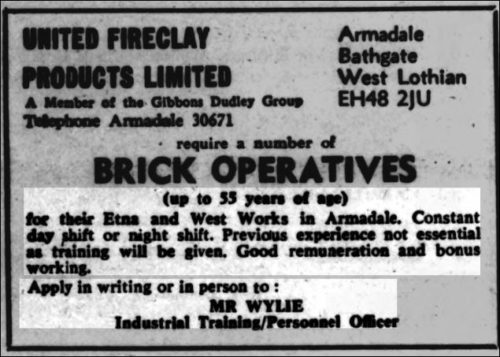

Below – 27/09/1974 – West Lothian Courier – West Lothian Courier – United Fireclay Products Limited require brick operatives at their West Works, Armadale and the Etna Brickworks.

Below – 05/09/1975 – West Lothian Courier – West Lothian Courier – United Fireclay Products Limited require brick workers at their West Works, Armadale and the Etna Brickworks.

<1978 – An article entitled ‘A look at the Armadale Works of United Fireclay Products’ which appeared c. 11/1978 in the Refractories Journal states ‘The ‘Etna’ brand has disappeared by the ‘Atlas’ brand continues to be used all over the world.

16/05/1980 – West Lothian Courier – Watchman. There is a vacancy for a watchman for evenings and weekend security duties at the company’s premises at Armadale. The position is particularly suitable to a person desiring lighter duties and the applicant may be in any age group, male or female. Interested persons are invited to call at the Etna Office or telephone Mr S. Wylie, personnel officer between 10 am and 3 pm Monday to Friday. United Fireclay Products Limited. Armadale, Bathgate, West Lothian EH48 2JU. Telephone Armadale 30671. Telex 727144. Manufacturers of refractory and building products. G. (Gibbons). A member of the Steetley Group.

1981 – The works were taken over by Steetley Brick. (Note – SBH – The previous entry would suggest the Steetley takeover took place in 1980 or earlier).

1983 – The works were taken over by Carradale aka Glasgow Iron and Steel Company Limited. (GISCOL)

1985 – Film – Etna Brickworks.

1996 – Ibstock purchases Redland Brick Ltd for £155 million, comprising of the former Redland and Steetley Brick businesses.

2008 – Compilation of stills by TeEnZiE – Etna Brickworks.

Dec 2011 – Works closed?

Below – 27/01/2012 – Photograph by John Wells – The Etna Brickworks during demolition.

Nov 2012 – Carradale Brick Company based at the Etna Works in liquidation.

Below – May 2019 – Photographs of the Etna and Atlas site.

Below – Etna wasters. These are large piles of melted brick. The ‘green’ bricks would appear to have either been too wet with regard to the water percentage in the clay or the kiln was too hot. These piles are about the size of a large car engine. (Note – SBH – I would love to be able to retrieve them one day!).

Below – Brick buttresses which formed part of a wall that surrounded the site.

Below – General views of the site showing a large quarry/clay pit, the old way bridge and demolished offices, concrete engine plinths and kiln structures.

.

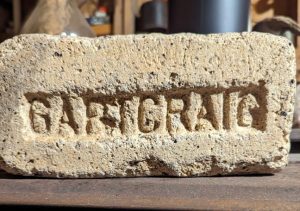

29/08/2019 – Daily Record – The Etna bricks of Armadale and Bathville.Throughout central Scotland, there must still be many thousands of structures built from “Etna” bricks.

These products of the Etna brickworks in Bathville are instantly recognisable by their sandy-brown fireclay colour, peppered with black rusty spots. These machine-pressed bricks are simply embossed with the word “ETNA”; the Greek goddess of volcanos.

The Bathville and Armadale area was once renowned for its bricks. Pits worked seams of fireclay that were associated with bands of sandstone, which provided the raw materials for heat-resistant firebricks used in furnaces and retorts.

Other works in the area produced “composition” bricks, usually formed from fireclay mixed with waste blaze from the bings of old collieries. The Etna brick seems to represent a halfway-house between these two brick types and was both stable to moderate heat in industrial processes, and resistant to frost.

The history of Armadale’s brick industry is difficult to untangle. During the mid 1860s, John Watson and his sons constructed the Bathville oil works, and associated works manufactured firebricks and composition bricks.

The Watsons became bankrupt in 1874, and most of their Bathville estate was then purchased by James Wood, a Paisley coal merchant.

The firebrick business at the Atlas works in Bathville was progressed for a period by Robert Fleming before this was also taken on by James Wood and in about 1885, Wood set up the Etna works to manufacture composition bricks, on a site adjacent to the Atlas firebricks works. The two sister works were to operate side by side for the next 80 years or so.

The Etna brick seems to have continued in production into the mid-1960s.