Cruden Bay is a small village located in Scotland, on the north coast of the Bay of Cruden in Aberdeenshire, 26 miles north of Aberdeen.

There are 2 records of brickworks located around the village. Both are referred to on Canmore – see links below

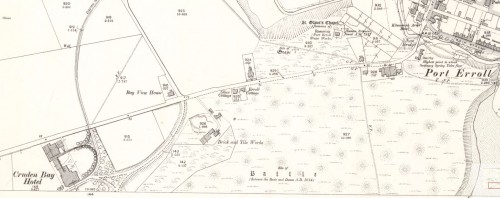

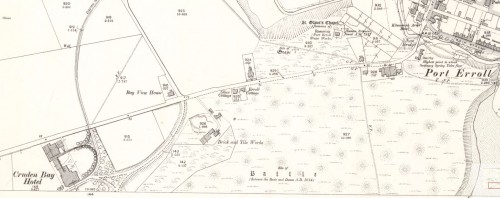

Canmore – This brick and tile works operated from 1882 to c. 1904; its site has been cleared.

Canmore – Cruden Bay Brick and Tile Works operated from 1902 – 1990 – Established in 1902 by a Mr Cruikshank, the works were producing 12,000 bricks per day by 1906. Field drains were also made in 1906 when 32 men and boys were employed. In 1947 the works were extended and modernised and by 1960 five million bricks a year were being produced. The works closed in 1990.

The kiln was coal-fired, being changed to gas sometime in the 1970s. Originally built as a 14-chambered Hoffman Kiln in 1902, it was extended to 16 chambers in 1947.

********************************************************

Not to be confused with the cleared brick and tileworks site at NK 085 360, for which see NK03NE 70.

A much-altered group of buildings in the process of being modernized. At time of writing a single-cylinder horizontal steam engine, of bore about 18 ins (0.45m) and stroke 36 ins (0.91m) with expansion valve gear, is still in situ, although disused; this was made by Marshall (works no. 38423). There is also a cable-worked railway of gauge 2 ft (0.61m) linking the works with the claypit. The single kiln is rectangular on plan, and of the Hoffman regenerative type.

J R Hume 1977.

This brick and tileworks operated from 1902 to 1990 and comprises a (continuous) Hoffmann kiln of twelve chambers. G Douglas and M Oglethorpe 1993.

The Cruden Bay Brick and Tile Works opened in 1902. The works made 3, 4 and 6-inch diameter field drain tiles and extruded bricks (bricks have 3 holes). It was the only works in Scotland to use the area above the kiln for drying. The kiln was coal-fired, being changed to gas sometime in the 1970s.

Originally built as a 14 chamber Hoffman Kiln in 1902, the works were extended to 16 chambers in 1947. A single-cylinder horizontal steam engine, delivering 135hp and manufactured by Marshall Son and Co., Gainsborough, was in use until replaced by an electric motor until 1973.

Other parts of the complex included a boiler house, workshop and washroom; self-acting lift from Drying Shed to ground level, kiln chimney, boiler chimney (demolished 1970); Tubway from clay pit (in use until 1979, then demolished); Ram from ground level to kiln top for coals and a small Bradley and Craven pan mill for crushing coal for kiln and breeze for mixing with clay. In 1976 the original steam-heated drying shed was replaced by a gas-fired hot air drying shed, with automatic mechanical handling equipment, made in Germany by LUNGI.

Information from GJ Douglas, Scottish Industrial Archaeology Survey, visited 1978, 1980 and 1982.

This site underwent a further photographic survey by RCAHMS in 1998. (Undated) information in NMRS.

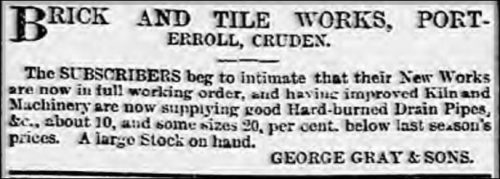

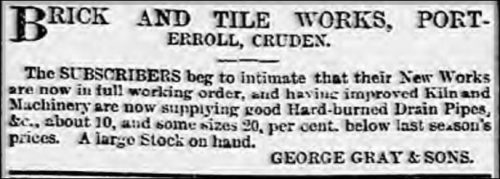

Below – 27/11/1885 – Aberdeen Evening Express – New works at the brick and tile works, Port Erroll, Cruden.

1886 – George Gray, Port Erroll, Cruden. (Page 88).

29/06/1897 – Peterhead Sentinel – …The boulder clay deposit at the Ward—now Port Erroll—has been turned to account within the last decade. Just behind the Lime Company’s sheds, in a hollow, apparently in dangerous proximity to the northern extremity of the drift sand, a brickwork has been erected, and with sand in abundance and coal at hand, and coal waste to got for a mere trifle, a good trade has been done in bricks and drain pipes &c. Between the brickwork and the mouth of the Cruden Burn, the deposit of clay is deep and seems good for many years’ working …

Below – 1899 – Cruden Bay Brick & Tile Works.

1901 – Directory of clay workers – G & J Gray, brick and tile works, Port Errol, Aberdeenshire.

1903 – J & G Gray, brickmakers, Port Errol.

03/01/1903 – Peterhead Sentinel etc – New chimney stalk being built at the Cruden Bay brick and tile works. Alex Cheyne, an Aberdeen bricklayer fell from a scaffold and broke 2 ribs.

06/10/1903 – Buchan Observer – To landowners, architects, builders and others. The Cruden Bay Brick and Tile Company, Cruden Bay Siding, G.N.S Railway, Port Erroll, Aberdeenshire are now in a position to supply all classes of common and pressed facing bricks and field drain pipes. Quotations on application. Having siding in works, orders can be executed with the utmost despatch. James Cruickshank, Managing director.

31/10/1903 – Peterhead Sentinel etc – Railway accident at Cruden Bay Brickworks … A night squad were repairing a soil slip near the siding at Cruden Bay Brick and Tile Company Works. Once completed the ballast train set out from Boddam however the points at the brick company’s siding had been wrongly set and the train ran into the dead-end stop. 8 persons injured.

22/07/1905 – Aberdeen Journal – Contribution to Aberdeen Royal Infirmary by Mr Cruikshank of Cruden Bay brick and tile work.

28/11/1905 – Banffshire Journal – Field drain pipes. Cruden Bay brick and tile company, Port Erroll. Only brickworks in Aberdeenshire having a railway siding into their works therefore in the best position to supply large stock of all sizes up to 12″. Quality guaranteed. Prices at any railway station on application. For the convenience of Turriff district supplies are kept at the stores of ” The Aberdeen Lime Company Limited”. William Wood agent. Telegram “brickworks” Port Erroll.

19/05/1906 – Peterhead Sentinel etc – Aberdeen Civil Engineers – Excursion to Cruden Bay Brick and Tile Works.

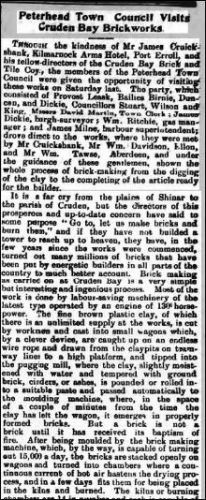

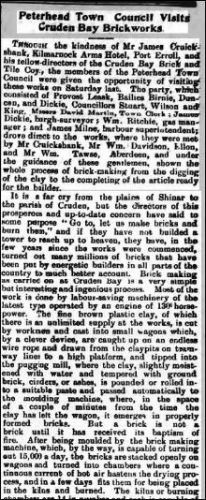

One of the most interesting and profitable excursions promoted by the Aberdeen Association of Civil Engineers, in inaugurating the summer session, took place on Saturday to Port Errol, when the members had the privilege of inspecting the works of the Cruden Bay Brick and Tile Company. Ltd. Including a number of guests, sixty-four gentlemen participated in the outing, which under delightful weather conditions proved a great success. The company left Aberdeen by the 12.40 train and were conveyed to Cruden Bay in specially reserved corridor carriages. On arrival, the party was received by Mr James Cruickshank, manager of the Brick and Tile Co., and prior to inspecting the works refreshments were provided. Thereafter, under the guidance of Mr Cruickshank, the various departments of the works were seen in full working operation, and one and all received much edification from the practical demonstrations before them as to the manufacture of such useful commodities as bricks, pipes, tiles, etc. It may not be interesting to give a description of the works, extensive, well-equipped, and thoroughly up-to-date as they are, as seen on Saturday.

DESCRIPTION OF THE WORKS

The works are situated about a thousand yards from Cruden Bay Station, at the lower end of a cutting 40 feet deep, and have been in full working operation for about 2 years. The exceedingly fine clay bed, which is practically of unlimited extent, covering several acres and only nine inches from the surface, runs along the side of the Cruden Bay Railway, with which the works are connected by a siding. By means of boring at the point where the works are situated, the bed was ascertained to be 86 feet deep, giving an estimated quantity of 75,000,000 bricks per acre. At the present the clay is only being worked to a depth of 35 feet, but it is proposed to work at a depth of from 55 to 60 feet as the pit widens, as the best clay lies between 25 and 55 feet from the surface, and lying as it does on the top of a bed of granite, contains no water. The clay is dug with spades and filled into barrows and tipped into small waggons, which carry about 10 cwts. The waggon is drawn by a steel wire rope up a gangway to the clay mill and emptied into a single shafted mixer, where water is added to reduce the material to the required consistency. From the mixer it passes into a revolving pan Mill, fitted with two edge rollers, weighing two tons each, and running on steel grids with 1/2 inch slots. By this means the stones are crushed and the clay passes to the ordinary pug mill, which forces the material in a continuous column to an automatic cutting table, which is a very ingenious machine, and where nine bricks are cut at a time and no waste ends left. The capacity of the machinery, which was constructed by Messrs T. C. Faucet, Ltd., Leeds, in 12,000 bricks per day. The wet bricks are set on small double-deck care capable of holding from 500 to 540 bricks each and conveyed per rail to the drying chamber, which is heated by exhaust steam.

The dryer, by the Wolff Dryer Company, consists of a single tunnel 110 feet long, twenty feet wide, and 6 feet 6 inches high, with five lines of rails and accommodating sixty-five cars. A five-inch header runs tho whole length of the dryer on each side, and coils of a one-inch piping cross between the headers, the larger number being at the lower end of the dryer. The rails have a fall of twelve inches in the length, and the cars find their own way to the end of the dryer. A tempering chamber has been added, but it has not been found necessary to fit it with steam piping. The capacity of the dryer is 25,000 bricks per week, but by the addition of live steam at night, the output can be increased to 60,000 per week. The condensed steam from the piping is pumped back by a self-acting pump to the boiler. Bricks for pressing are set on the cars, allowed to settle for twenty-four hours either in the drying floor or in the tempering chamber, and repressed by a Fawcett’s duplex press, capable of turning out about 6000 bricks per day.

A large part of the company’s manufacture consists of field drain tiles, for which the clay is admirably suited, and for the distribution of which the works are most conveniently situated. The clay for the pipes goes through the same process as that for the bricks and is placed for use as required by the pipe-makers. The pipe machines occupy a drying shed one hundred and four feet long and sixty-six feet wide-the cement floor of which is laid on bricks set on end. The other pipe machine is on the drying loft above the Hoffman kiln, to which the clay is hoisted by means of a chain elevator. The pipe machine consists of two revolving cylinders, which force the clay through Dies in a continuous stream on to cutting cables, where the pipes are cut three lengths at a time. The small pipes are wheeled in bogies from the pipe machine to the drying racks, where they are placed in shelves for drying.

The bricks and pipes, after being dried, are conveyed to the kiln in cars and barrows. The kiln, a continuous one, is an ordinary fourteen chamber Hoffman, fired wholly from the top with dross. The bricks are set in the bottom of the kiln, and the pipes on the top, seven to seven and a half chambers being burned per week, while a complete round of the kiln takes about thirteen days. Bricks and pipes for despatch are wheeled direct to the railway from the kiln, a large proportion never being stocked at all. Power for the machinery is supplied by a tubular boiler installed by Messrs James Abernethy &a Count., Aberdeen and is worked at a pressure of a hundred pounds to the square inch. The engine is by Messrs Marshall, Sons & Co., Gainsborough, of their K type, with a 16-inch cylinder and 30-inch stroke, and of 135 indicate h.p. and 125 effective h.p. The exhaust steam passes to pipes connected with the patent tunnel dryer and steam floor and can be directed to either or both as required. The water supply for the boiler is obtained by a small suction and force pump situated at the Cruden Burn, 500 yards distant. Altogether the works, as indicated, are thoroughly equipped, and many of Saturday’s visitors were amazed at the rapid, easy and simple method of manufacturing the clay.

VISITORS ENTERTAINED

After completing their inspection of the buildings the visitors were entertained to tea by the Brick and Tile Company in the Kilmarnock Arms Hotel. Mr James Cruickshank occupied the chair, and the directors of the company present were:-Mr P. Tawse, contractor, Aberdeen; Mr W. D. Ironside, C.E., Aberdeen: and Mr W. Davidson, architect, Ellon. The company also included:-Mr G. R. G. Conway, vice-president of the association: Mr R. Nicol, ex-president: Mr G. R. G. Conway, vice-president: Mr Wm. Simpson, secretary, etc., etc. After an excellent tea.

The Chairman, on behalf of his co-directors and himself, said they were very pleased to have had such a company as the members of the Aberdeen Association of Civil Engineers there that day. They considered it a great honour that the association should have considered it worth their while to pay a visit to the works. The company had not been at Cruden Bay that long, but they hoped to stay a good while (applause). It was a pleasure to see so many members of the association present, and he hoped when they went out to the world they would not forget their visit to Cruden Bay (applause).

Mr G. R. G. Conway, on behalf of the members of the association, said he had to thank the Cruden Bay Brick and Tile Company for their courtesy, consideration, and hospitality that day. Their visit, he was sure, had been to every one of them one of pleasure and interest. The brickmakers art was, as they knew, one of the oldest in the world. Those of them who read the Bible would remember that they made bricks away back in the days of Egyptians.

In their visit that day they had seen bricks made from very fine clay; they had seen works which were quite up-to-date in every respect, and the goods manufactured would bear a good deal of inspection by engineers. The bricks made there were of excellent workmanship (applause). At the head of the company in the person of Mr Cruikshank, there was a gentleman who was thoroughly familiar with the work and who was doing his best to push the industry and make it one of the best in that part of Scotland (applause). They also had to thank Mr Ironside, Mr Davidson, and Mr Tawse, Mr Cruickshank’s co-directors, who were with them that day for their great kindness and courtesy. The members of the association thoroughly appreciated the kindness extended to them, and they hoped when the company developed and the works extended over fifty or sixty acres, they would ask them back again to the works (applause).

The company thereafter broke up into small groups, and short excursions were made to places of interest in the neighbourhood prior to train time. The party returned to Aberdeen by the 7.28 p.m train, having spent a thoroughly enjoyable and pleasant outing. The afternoon’s arrangements were, as usual, in the hands of Mr William Simpson, assistant harbour engineer (secretary of the association), and were conducive to a successful gathering.

10/08/1907 – Shetland Times – Established 1837, The Aberdeen Lime Coy Ltd, Coal, lime and cement importers are the sole agents for the Cruden Bay Brick and Tile Company. Mr A T Robert Manager.

15/01/1908 – Aberdeen Journal – Sewerage Committee of Aberdeen Town Council meet and agree to purchase fire clay pipes and syphon traps and the order of the Cruden Bay brick and tile company was accepted, amounting to £223 18s 4d for fire clay pipes and £32 1s 4d for syphon traps.

Below – 14/07/1908 – Buchan Observer – Peterhead Town Council visit Cruden Bay Brickworks.

Below – 30/03/1909 – In the possession of John Ryan – Cruden Bay Brick and Tile Company business card. Jas Cruickshank, Manager.

30/03/1909 – Fraserburgh Herald – Excursion to Cruden Bay. On Saturday afternoon, the members of the Fraserburgh Building Construction Class in the Academy Evening School drove to Cruden Bay for the purpose of inspecting the brickworks and the power station at the hotel. There they met their teacher, Mr Dawson, along with members of his Peterhead class and the whole party under the kindly guidance of Mr Gray, the manager of the brickworks, examined the various steps and the machinery used in connection with brickmaking …

10/10/1910 – Aberdeen Journal – The finance committee of the Aberdeen Harbour Board report having tenders for the supply of ordinary materials for the harbour works for the year from 1st November next – bricks and drain pipes – Cruden Bay Brick and Tile Co.

13/12/1911 – Aberdeen Journal – Sewerage Committee of Aberdeen Town Council meet and agree to purchase fire clay pipes and syphon traps for the ensuing year when the offers of Cruden Bay brick and tile company of £131 2s 7d for fire clay pipes and £26 11s 7d for syphon traps were accepted.

1912 – 1913 – Cruden Bay Brick and Tile Co, Kittybrewster Station, Bedford Road.

31/12/1913 – Aberdeen Journal – The finance committee of the Aberdeen Town Council appoint contractors for the Police Department – bricks Cruden Bay Brick and Tile Co.

17/04/1918 – Aberdeen Journal – Sheriff Dudley Stuart presided yesterday at the Aberdeen Sheriffdom Appeal Tribunal. Lieutenant Robertson was the National Service representative. Mr Cruickshank, Kilmarnock Arms Hotel, Fort Erroll, manager of the Cruden Bay brick and tile company appeared for Robert Mutch (38) kiln setter, 24 Main Street, Port Erroll and stated that Mutch was 1 of 2 mean necessary as skilled labourers to keep the kilns going for important work in making drain pipes so greatly required by farmers extending the cultivation of their land, and those pipes were only now supplied in the North by the Seaton Brick and Tile Co and the Cruden Bay Brick and Tile Co. On the motion of Lieut Robertson, the case was remitted to the Board of Agriculture for consideration.

10/01/1920 – The Scotsman – Joint-stock companies registered in Scotland this week – Cruden Bay Brick and Tile Company Limited ( private company) to take over the business carried on at Port Erroll, Aberdeenshire and elsewhere by the Cruden Bay Brick and Tile Company. Capital £12,000 in £1 shares.

08/03/1921 – Aberdeen Journal – George Hall (66), Builder, 139 Desswood Place Aberdeen dies. He was a director of the Cruden Bay Brick and Tile Coy Ltd.

1923 – 1924 – Kelman, Wm., traveller (Cruden Bay Brick & Tile Co.), 79 Sunnyside Road and James McLeod, storekeeper (Cruden Bay Brick and Tile Co.), 93 Chapel Street.

18/12/1925 – Aberdeen Press and Journal – Cruden Bay Brick and Tile Coy Ltd, Cruden Bay, Aberdeenshire. Works Cruden Bay and Newark, Tipperty. Distributing depot – Kittybrewster Station (Off Bedford Road, Aberdeen). Manufacturers of best red clay bricks, field drain pipes, well linings etc. Builder’s merchants – fireclay drainage goods, vent linings, chimney cans, feeding troughs etc all stocked at Kittybrewster Station. Also, lime and cement supplied. Telegrams – ‘Brickworks’ Cruden Bay. Telephone 4 Cruden Bay and 1368 Aberdeen. Inquiries solicited.

10/01/1927 – Aberdeen Journal – Cruden Bay Brick and Tile Coy Ltd along with friends and family have their annual ‘At home’ in the public hall and Mr Jas Cruikshank made a speech. Mr A Robb was present as secretary.

23/12/1927 – Aberdeen Journal – The successful contractors for the Streets and Roads Dept of Aberdeen Town Council for 1928 are … bricks and field drains – Cruden Bay Brick and Tile Co.

29/06/1928 – Aberdeen Journal – Appeal for contributions to the new hospital – Cruden Bay Brick and Tile Co Ltd per James Cruikshank, Secretary £50, Employees of Cruden Bay Brick and Tile Co Ltd £8 10s and Mr M Simpson Cruden Bay Brick and Tile Co Ltd.

02/11/1929 – Dundee Courier – Fatal Accident at Cruden Bay brick and tile works. Allan Robb, (20), son of Mrs Robb, Pleasant Cottage, Cruden Bay, Aberdeenshire was fatally injured when assisting with loading and shifting railway wagons in the works siding of the brick and tile co, with whom he was employed. One of the wagons rebounded and he was crushed between 2 of them. He died in Aberdeen Royal Infirmary.

17/12/1930 – Aberdeen Journal – New Aberdeen Road to cost over £7000 … unemployed workers will be used as labour. A new sewer on the lands of Stocket will also be laid at a cost of £245. Bricks and field drains supplied by Cruden Bay Brick and Tile Co.

16/05/1931 – Aberdeen Journal – Major fire at Braehead, Cruden Bay. When the blaze was seen from the Cruden Brick and Tile Company’s factory nearby the hooter sounded to cease work and the employees numbering about 30 ran across the field to render assistance.

14/09/1931 – Aberdeen Journal – Mechanical Society of Aberdeen visit Cruden Bay Brickworks. Mr James Cruikshank was a director of the brickworks at the time and Mr Gray was the foreman.

22/03/1932 – Aberdeen Journal – Cruden Bay Work Enterprise – After having been stopped for 2 1/2 months for the purpose of installing a new boiler, the one in use proving to be too small for the increasing work, Cruden Bay Brick and Tile Co Ltd have restarted manufacturing. The new boiler, a Lancashire one 30ft by 7ft 6″ with Meldrum furnaces and for a working pressure of 120lb. Messrs Abernathy and Co Ltd, Aberdeen had the contract for the boiler and fittings and Messrs Wm Farquharson and Son, builders, Aberdeen the brickwork and boiler seatings. During the stoppage, the machinery, kilns and drier were thoroughly overhauled. 35 hands are employed by the Company and the Works are now going full time. This is the only occasion on which the kiln fires have been out for the past 8 years.

12/04/1937 – Aberdeen Journal – Robert Mutch born in Cruden 57 years ago died. He worked for 25 years at Cruden Bay Brick and Tile Co Ltd

1942 – 1943 – Cruden Bay Brick and Tile Co Ltd, Bedford Road

28/05/1947 – Aberdeen Journal – New Plant to increase output – In an all-out bid to increase the supplies of materials desperately needed for building, the Cruden Bay Brick and Tile Company Ltd, one of the biggest firms of its kind in Scotland, are installing new machinery which will step up their yearly production by 25%. The firm closed down a week ago for 4 months while the latest type of British machinery is installed. This temporary stoppage, however, will not affect production immediately. “We managed to lay in a stock before we closed down” Mr J.P Mearns, manager, told a reporter of the Press and Journal yesterday. All our commitments will be met while the firm is closed down. Mr Mearns revealed that the machinery was ordered in the week the war ended. “Once the machinery is installed our input will be increased by over 1,000,000 bricks a year” he added. ” We are keeping on a number of our men during the close down. The remainder have managed to secure temporary employment”. ” All the men will be back to work for us when we are ready to go into full production again about the beginning of October”

11/05/1950 – Aberdeen Journal – Clerk bookkeeper (male) required for Cruden Bay. Previous experience essential. House available. Applications with particulars and salary required to Cruden Bay Brick and Tile Co Ltd

16/10/1950 – Aberdeen Journal – Driver required for excavator – post now filled. Thanks to all applicants. Cruden Bay Brick and Tile Co Ltd.

24/03/1952 – Aberdeen Evening Express – 47 years with a brick company. The longest-serving employee of the Cruden Bay Brick and Tile Company retires in a weeks time. He is Mr William Kelman, the Aberdeen Branch Manager of the firm. He has seen vast changes take place in the building industry in the North East during the last half-century … He joined the Company in 1905, 3 years after it was founded …

20/10/1954 – Dundee Courier – For sale – Sentinel Diesel 7t end tipping lorry ( 1949). Taxed to the end of the year. Can be seen in Aberdeen. Offers to Cruden Bay Brick and Tile Co Ltd.

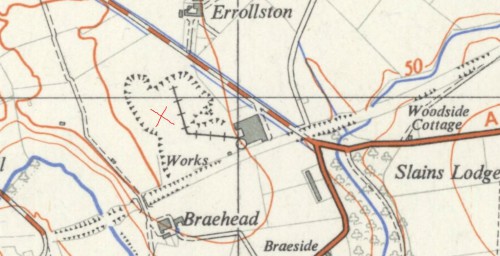

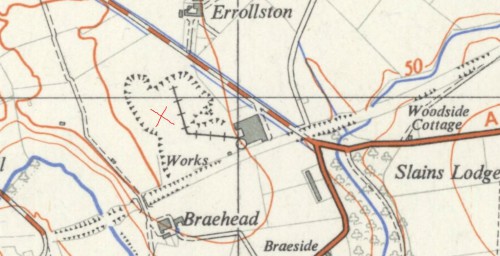

Below – 1957 – Cruden Bay brick & Tileworks – marked with a red X

1961 – 1962 – A directory of British clay products and manufacturers – Cruden Bay Brick and Tile Company, Cruden Bay, Aberdeenshire. Tel Cruden Bay 260. Common bricks.

07/03/1970 – Aberdeen Press and Journal – Merged – Two well-established brick and drain tile manufacturing firms in the North and Northeast have merged to provide a more efficient service to their customers. They are the Cruden Bay Brick and Tile Co., Ltd., who have premises at Cruden Bay and Tipperty, and Sutherland Bricks Ltd. Brora. Mr Ronald Bannerman. director and general manager of the Cruden Bay company, who acquired control of Sutherland Bricks, said: ” We will have a better service all round, and continuity of employment for the people working at the places. The Cruden Bay company have a total workforce of 50 and Brora 25. No expansion programme or extra jobs are planned for the near future at any of the works”

Below – 09/03/1970 – Aberdeen Press and Journal – Cruden Bay Brick and Tile Co Ltd have acquired control of Sutherland Bricks Ltd, Brora. The merging of these well-established Companies will provide a more efficient service to the Agricultural and Building communities in the North and North-east of Scotland. Although both companies will continue to operate as separate units, their joint activities will be aimed at the production of sufficient Bricks and Drain Tiles to satisfy the needs of the area as promptly and as cheaply as possible. Mr W. Stuart Sutherland of Sutherland Bricks Ltd. will continue to be actively associated, with the Company and to serve on the Board of Directors. A. Middleton, Secretary, Crudcn Bay Brick & Tile Co. Ltd.

Below – 27/10/1970 – Aberdeen Evening Express – Cruden Bay Brick and Tile Co Ltd incorporating Sutherland Bricks Ltd, Brora.

Below – 20/04/1971 – Aberdeen Press and Journal – Cruden Bay Brick and Tile Co Ltd incorporating Sutherland Bricks Ltd, Brora. Stockists of spigot and faucet pipes and general building materials. Works at Cruden Bay, Aberdeenshire and Brora, Sutherland and Tipperty Ellon and Aberdeen Depot, 17 Back Milton Road, Aberdeen.

Below – 16/12/1977 – Aberdeen Press and Journal – Brora Council looking to purchase land there owned by the Cruden Bay Brick Co Ltd.

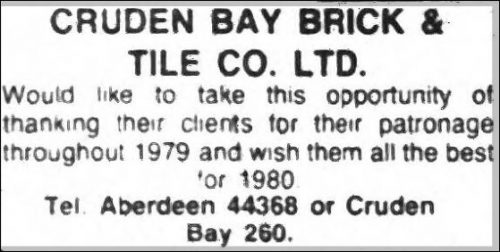

Below – 31/12/1979 – Aberdeen Evening Express – Cruden Bay Brick and Tile Co Ltd.

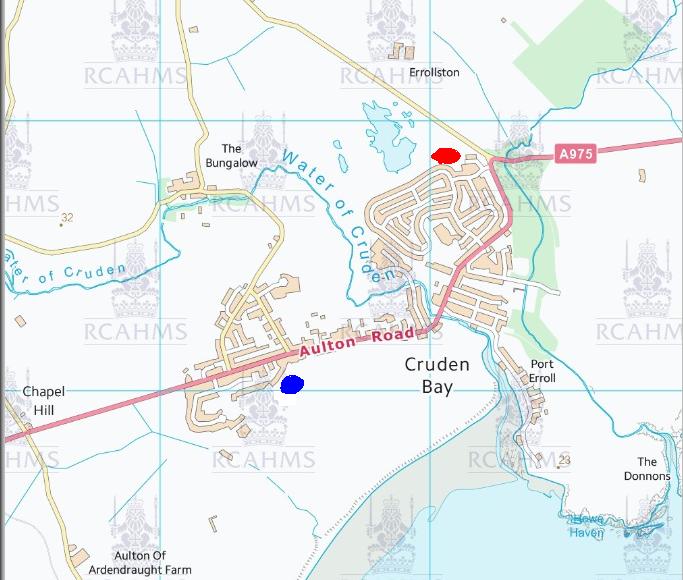

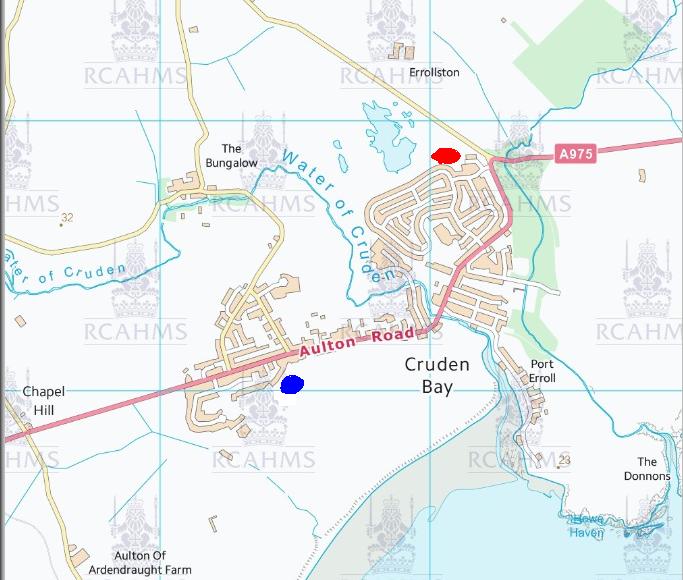

Below – Blue marker below depicts the location of the original works

The red marker below depicts the location of the latter works

During a site visit on 13/08/2014, the following Cruden Bay manufactured bricks were recovered from the disused brickworks.

Below – Cruden 3 Bay brickmark

Below – Brick stamped ‘3’ – The same style of numerals as the example above.

Below – Cruden Bay – no numbers.

Below – 3 cored brick – see picture below for similar stacked in a kiln.

Below – An oversized brick found on-site in numbers and believed to have been manufactured there. Measuring 9″ x 5 3/4″ x 3″

.

Below – This type of brick was found in abundance on the site and this particular example has been personalised by someone prior to the brick being dried.

Curiously they have written the word ‘Thur’ in the wet clay. It may have been a reference to the day the bricks were going to the kiln for firing or the day they would be ready once fired?

Below – And similarly a brick handwritten with ‘FRID’. This was found in a pile of bricks in Aberdeenshire and is believed to have been manufactured at Cruden Bay.

Below – Brick stamped ‘5’ and found on-site by Ian Suddaby. Undoubtedly a Cruden Bay product.

Link to Cruden Bay bricks

The following brickmarks were also found on-site during the visit on 13.08.2014 -Dykehead, Dykehead Bonnybridge, Stein, Thistle, Glenboig, Glen, Caledonia, Atlas, Atlas + A, Forth A, T16 ( unidentified maker). An Eagle and Ignis (unidentified maker) brick have also been previously recovered there.

The Brick Works at Cruden Bay were producing 5 million bricks a year in the 1960s.

1983 – Aberdeenshire Council info – Brick and tile works, built in the early 20th Century. A much altered group of buildings, with a single-cylinder horizontal steam engine with valve gear, which was still in situ in 1976, but disused. This was made by Marshall, works no.38423. There is also a cable-worked railway linking the works with the claypit. The single kiln is rectangular on a plan of the Hoffman regenerative type. Bore engine 0.45m by 0.91m; railway gauge 0.61m. During WWII two men were killed in a bombing raid that partially destroyed part of the buildings. Latterly disused and now demolished.

RCAHMS – are in possession of a c 1950 handwritten report which lists bricks manufactured on-site … common red bricks (2 sizes), common red harling bricks, common red radiated bricks, common red circle and header, common red coping bricks, and common red bull-nosed bricks, as well as rybat bricks, boiler topers, agricultural drain tiles and milled clay (company leaflet c 1950) …

They also have a rubbing of the brick found at the site which reads Turnbull Dykehead, – The brick in question was made at Dykehead fire clay works, Bonnybridge, Falkirk by

George Turnbull 1906 – 1962